Power line noise countermeasures using common mode choke coils

In Part 1, we explained that large-scale, complex, and high-speed vehicle-mounted networks will be installed in CASE era cars, and this requires technology for operating while ensuring high safety and reliability. Murata Manufacturing Co., Ltd. ("Murata" below) provides inductor products for contributing to advancements in vehicle-mounted networks and their safety and reliability. In Part 2, we focus on two product categories among the vehicle-mounted inductor products developed and provided by Murata, and we asked engineers about the strengths of these products and the direction of future advancements. These two product categories are the common mode choke coil (CMCC), which is a noise suppression component for preventing malfunctions in electronic control systems, and the PoC filter, which enables reductions in the number of cables.

--What types of noise suppression components are used for increasing reliability in vehicle-mounted networks?

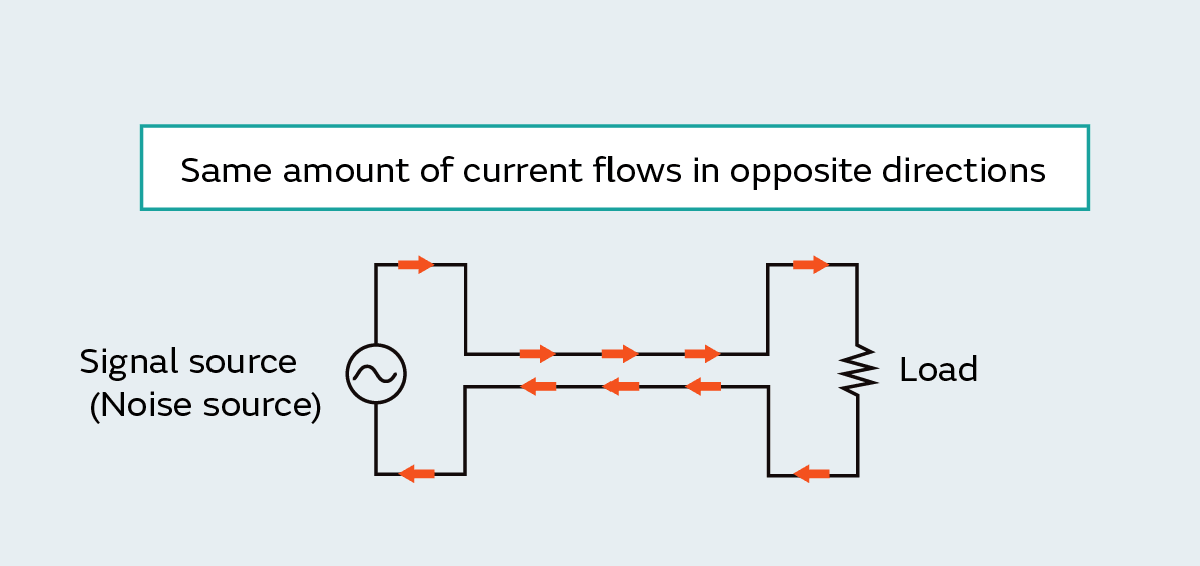

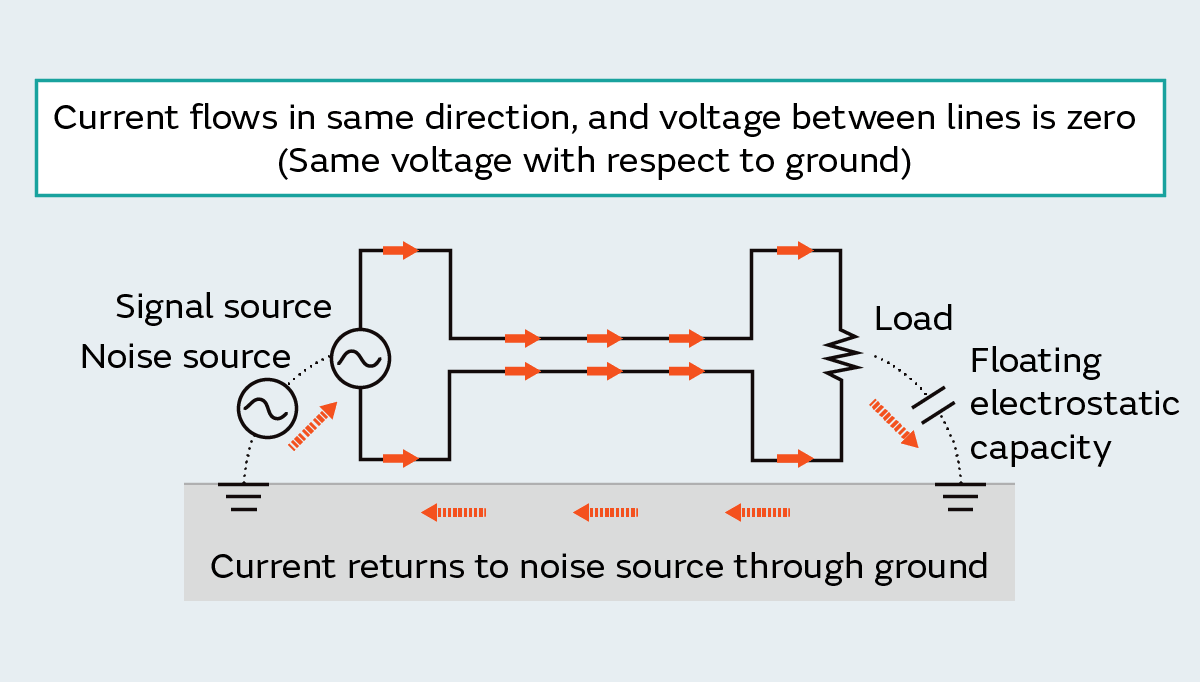

The noise mixed in with data in vehicle-mounted networks consists of two types: Normal mode noise*1 and common mode noise. Ferrite beads*2, capacitors, and resistors are used to remove normal mode noise, and CMCCs are used to remove common mode noise.

Common mode noise is generated when a phase shift occurs in a differential signal in a cable, connector, or other part. Differential signals are frequently handled in vehicle-mounted networks, and so CMCCs are commonly used. Murata provides products that satisfy the standards for CAN/CAN-FD, vehicle-mounted Ethernet, and other vehicle-mounted networks.

*1: Normal mode noise is noise generated when a noise source is located in series with the signal source. The noise is transmitted to the computer and other devices over the signal lines.

*2: Ferrite beads are an electronic part for changing the high-frequency noise to thermal loss and removing it. A lead wire passes through the beads which are made of ferrite, a magnetic material. When a current flows through the lead wire, a magnetic flux is generated in the ferrite beads, which causes it to act as an inductor. Ferrite enables large losses in the high-frequency range, and so it is used to enable effective absorption of high-frequency noise.

--What are the features and advantages of Murata's vehicle-mounted noise suppression components?

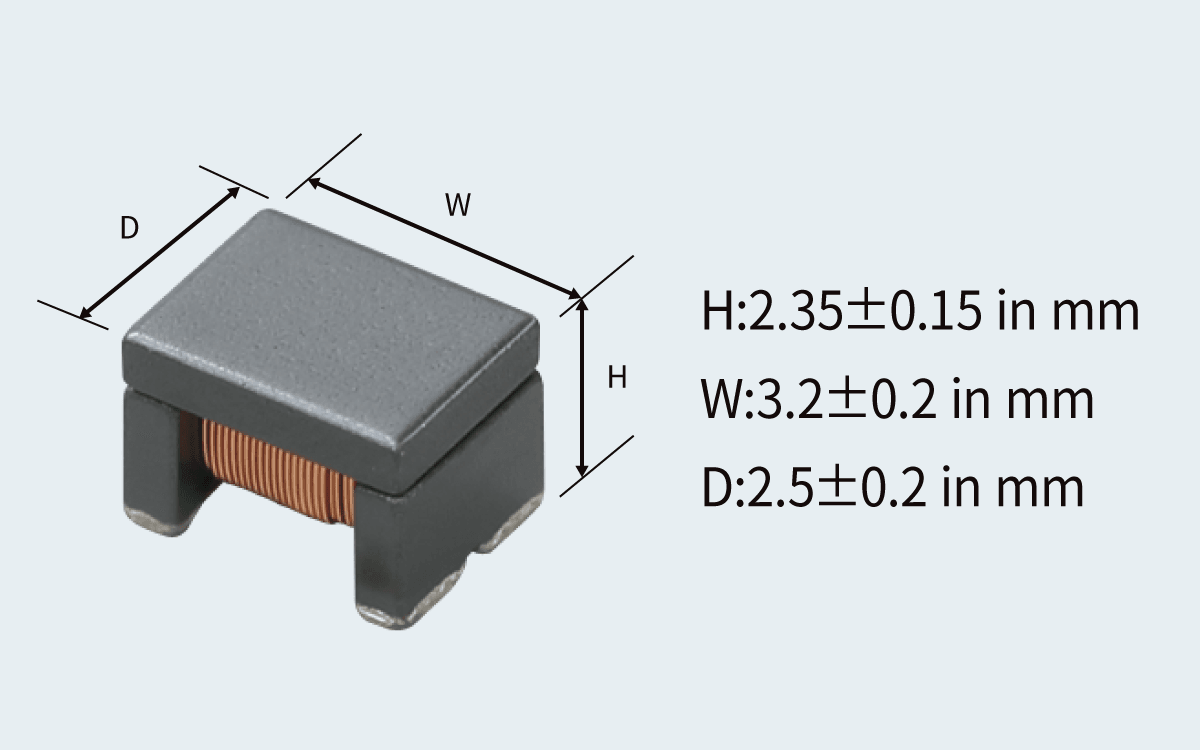

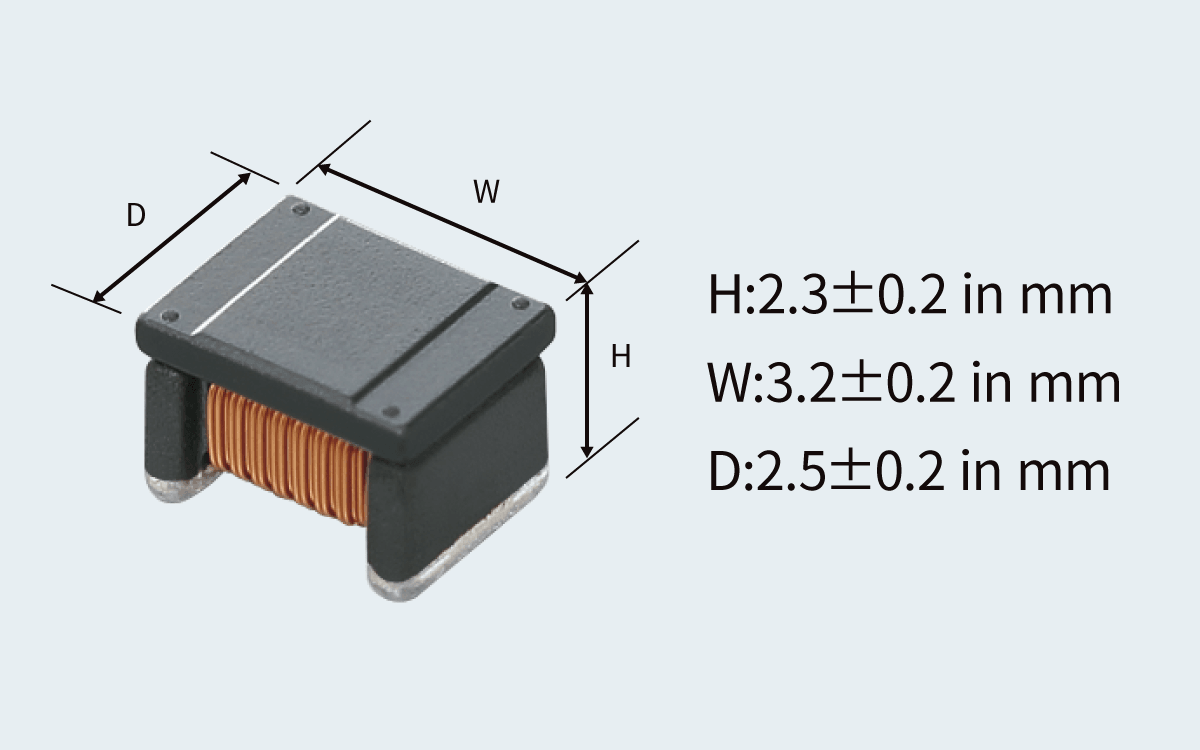

Murata's noise suppression components provide unrivaled performance in a compact size. For the CMCCs for CAN*3, which is a type of vehicle-mounted network, typical systems used a large-size toroidal type where copper wires are wrapped around a ring magnet or a 4532 (4.5 mm x 3.2 mm) size automatic-winding type. Murata was among the first to develop and release a 3225 (3.2 mm × 2.5 mm) size automatic-winding CMCC.

*3: Controller Area Network (CAN) is a vehicle-mounted network standard that was developed in 1983 by Robert Bosch of Germany. A large number of automobile manufacturers use it as an industry standard technology for engine and brake control, fault diagnosis, and other operations. Because it has a high resistance to noise and includes powerful error detection mechanisms, among the numerous available vehicle-mounted network standards, CAN is selected for use in sections that require particularly high reliability.

Murata is also superior in its capability to implement mass production of products while maintaining high quality. In the consumer market, Murata has a proven track record of stable production while maintaining high quality for CMCCs at high volumes that far exceed the level of vehicle-mounted CMCCs. Going forward, as vehicle-mounted networks become more advanced and their use becomes more widespread, the number of CMCCs being used is expected to increase significantly. At Murata, we consider our designated role for this era to be the supplier of large volumes of CMCCs with more compact designs.

--Car functions are expected to become more advanced, and vehicle-mounted networks are expected to continue to evolve. Within these technological trends, what are the technical requirements for noise suppression components?

For CMCCs for CAN and Ethernet, reduced loss is required, and the characteristic known as mode conversion takes on even greater importance. The mode conversion characteristic indicates the degree that normal mode is converted to common mode, and a smaller value indicates that common mode noise is less likely to occur.

A CMCC consists of a combination of two coils, but to improve the mode conversion characteristic, the symmetry of this coil pair must be increased. Murata revamped the coil design and winding method for successfully increasing the symmetry.

--Going forward, in which direction will technical development proceed for vehicle-mounted CMCCs?

We will be studying both the element structures and materials for CMCCs for CAN and for Ethernet to enable compliance with new vehicle-mounted network standards. Murata's strength in compact design will also be implemented while watching market trends and network standards.

--Next, we asked about the PoC filters, which are inductor products that simplify the vehicle-mounted network structure. To start off, the PoC filter is an electronic component that plays what role in a vehicle-mounted network?

The PoC filter is an electronic component that is essential for reducing the number of cables comprising the vehicle-mounted network.

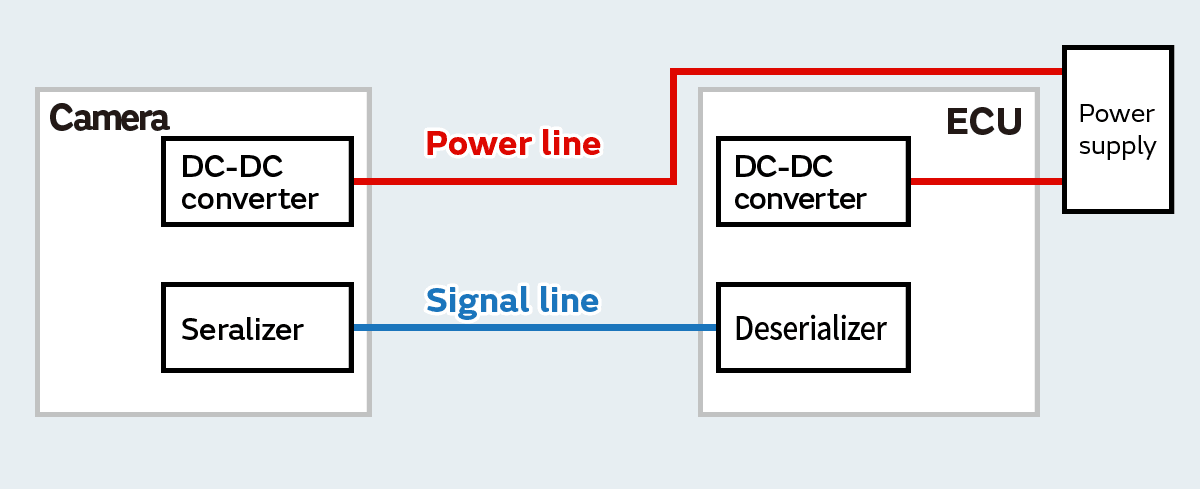

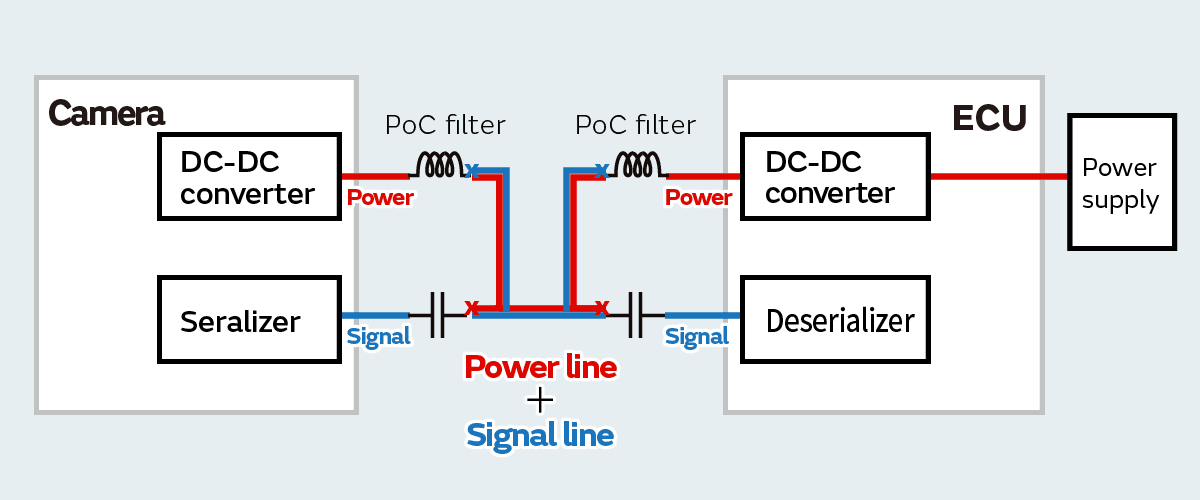

Cars with an advanced driver assistance system (ADAS) and self-driving cars have a number of cameras that collect information for determining the driving environment. These cameras are connected to a line for transmitting data signals and a line for supplying power. PoC is a technology where these two lines are combined and both the data signals and power are sent over a single coaxial cable, and a PoC filter is an inductor product that is used when separating the data signals and power supply. The characteristics of the inductor, where low-frequency signals pass through easily and high-frequency signals have difficulty passing through, are used to allow low-frequency DC power to pass through and to block high-frequency data signals.

In the vehicle-mounted network, PoC is used in SerDes*4, which is used for transmission of large-capacity data such as video signals. In the signal line, a capacitor is inserted so that data signals only pass through, and in the power line, an inductor is inserted to prevent the entry of high-frequency signals. PoC is used in SerDes to reduce the number of cables and minimize any increase in weight.

*4: SerDes (Serializer/Deserializer) refers to circuits that convert between the serial bus and parallel bus in each direction. In high-speed networks, this is used for serial connections between electronic devices that operate using internal parallel buses.

--What points must be taken into consideration when developing the inductors used in PoC filters for SerDes?

PoC filters require an inductor with characteristics where the impedance becomes higher at the frequency of the transmitted data signals. However, the frequency band of the inductor required for SerDes is a considerably wide range from MHz to GHz, and so a high impedance must be obtained over a wide range.

Murata's PoC filters incorporate a special design that enables them to provide a high impedance over a wider range compared to typical inductors that are the same size.

--A wide variety of sensors and electrical components are expected to be installed for realizing more advanced ADAS and self-driving cars. How will PoC filters change in response to these technological trends?

The SerDes consumption current connected to cameras is around several hundred mA, but if the PoC applications within the car are many and varied, the consumption current could increase. Also, if communication speeds become even faster, the signal frequency range will expand even more. For this reason, we think that the inductors for PoC filters will require larger currents and wider range performance in the future.

More compact designs for PoC filters will also be required. To make more compact PoC filters, either the quantity of inductors, resistors, or other elements must be reduced or the element size must be reduced. In order to reduce the quantity of elements, the frequency range that can be covered by a single element must be expanded. On the other hand, in order to reduce the element size, size-reduction technology must be established while also maintaining the same characteristics. In the development of inductors for PoC filters, the attaining of both higher performance and smaller sizes is an issue, and Murata is focusing on this key point in taking on this challenge in its technological development.

--I think that attaining both wider frequencies and a more compact size must be a tremendously difficult task. It must take considerable time. On the other hand, vehicle-mounted networks are rapidly evolving. What actions are you taking to meet immediate technological needs?

PoC filters have strict performance requirements, and it is extremely difficult to meet these requirements with a single component. And so, typically, multiple inductors and resistors are combined to assemble a PoC filter having the required characteristics. This is why Murata has a wide selection of inductor products with a wide range of characteristics, from large products for low frequencies to small products for high frequencies. Murata is focusing on design support for PoC filters and are using characteristic simulations to study how to prepare guidance tools that can provide the optimum inductor combination for specific required characteristics.

* Murata released "Bias-T Circuit Inductor Selection Tool" as a result of these efforts.

In the major transformation of cars based on CASE, a wide range of peripheral technologies must be provided together for implementing various advanced technology in the car, such as artificial intelligence (AI), which is the brain of the self-driving car, and the inverter and battery, which are the heart of the electric car. Noise suppression measures, PoC, and other technology for vehicle-mounted networks that are realized using Murata's vehicle-mounted inductor products are representative examples of peripheral technology that is truly essential for implementing advanced technology.

To be among the first to install cutting-edge vehicle-mounted networks in cars and to enter the market at an early stage, noise suppression components and similar products must be prepared first. Further advancements in Murata's noise suppression components and PoC filters can be said to be essential for the future evolution of CASE era cars. In the same way that the evolution of Murata's electronic components spurred further advancements for entire devices in the smartphone electronic components field, we also expect Murata to be an essential presence for achieving further advancements in CASE era cars.