Common mode choke coils for automotive LAN

Companies in the car industry around the world are involved in revolutionary changes to car functions and its structure based on CASE (Connected, Autonomous/Automated, Shared & Service/Safety & Security, Electric). A fundamental revolution is occurring where the car itself is virtually being reinvented, and the changes that will occur in cars over the next ten years will probably exceed the number of changes in cars that occurred over the last fifty years.

It would probably be more correct to refer to CASE era cars as electronic equipment. Since the antilock brake system (ABS)*1 was first introduced to commercial cars in 1978, the number of vehicle-mounted mechanisms that perform electronic control have been gradually increasing. Until now, all functions installed in the car, from basic functions such as operating, stopping, and turning, up to the functions providing safety, comfort, efficiency, added value, and more, have been operated using an electronic control system. Now a single car is installed with more than 20 to 30 control computers (ECUs)*2 and countless numbers of sensors for detecting the mechanism operating status and driving environment.

*1: An antilock brake system (ABS) refers to a system that prevents locking of the wheels which occurs when breaking on a slippery road surface. When a sensor detects a situation where the wheels could lock, the brake pressure is automatically adjusted so that the steering wheel can be used safely even if the brake was pressed down. The ABS was the first preventative safety (active safety) device installed in cars for preventing accidents before they happen and has led to today's advanced driver assistance systems (ADAS).

*2: The electronic control unit (ECU) refers to a computer that controls the vehicle-mounted equipment. Some car models already have more than 100 ECUs per vehicle, and the number of mounted ECUs has tended to increase as vehicle-mounted device control becomes more advanced.

As we strive to develop a fully self-driving car, which can be said to be a massive unit of computerization, vehicle-mounted electronic control systems will continue to become more advanced. We will see steady performance improvements in individual ECUs and sensors. In addition, recently, improvements in vehicle-mounted network performance and reliability for connecting the large number of ECUs and sensors and exchanging data among them have had a significant impact on functional improvements for the entire car. This is because linkage operations are now being used for a wide range of functions such as automatic control of steering while taking into account the information for the driving environment obtained from cameras, position information obtained by GPS, and other data.

It is challenging objective to improve the performance and reliability of vehicle-mounted networks. This is the case because higher speeds and complexity of networks can result in the mixing of external noise in the signals of the cables connected to the ECUs and sensors, increasing the likelihood that faults occur. Since high-speed communication cables are closely-packed into a narrow space, car interior environments can present extremely harsh environments for improving the reliability of vehicle-mounted networks. To realize even faster vehicle-mounted networks, reliability improvements using noise suppression components have become essential.

Innovations are also needed to simplify the configuration of vehicle-mounted networks. The weights of the cables installed in cars have already reached 50 to 60 kg in large-sized car models. Building vehicle-mounted networks with fewer and more lightweight cables will lead to improvements in fuel efficiency and lower electrical costs for electric cars, while improving car maneuverability.

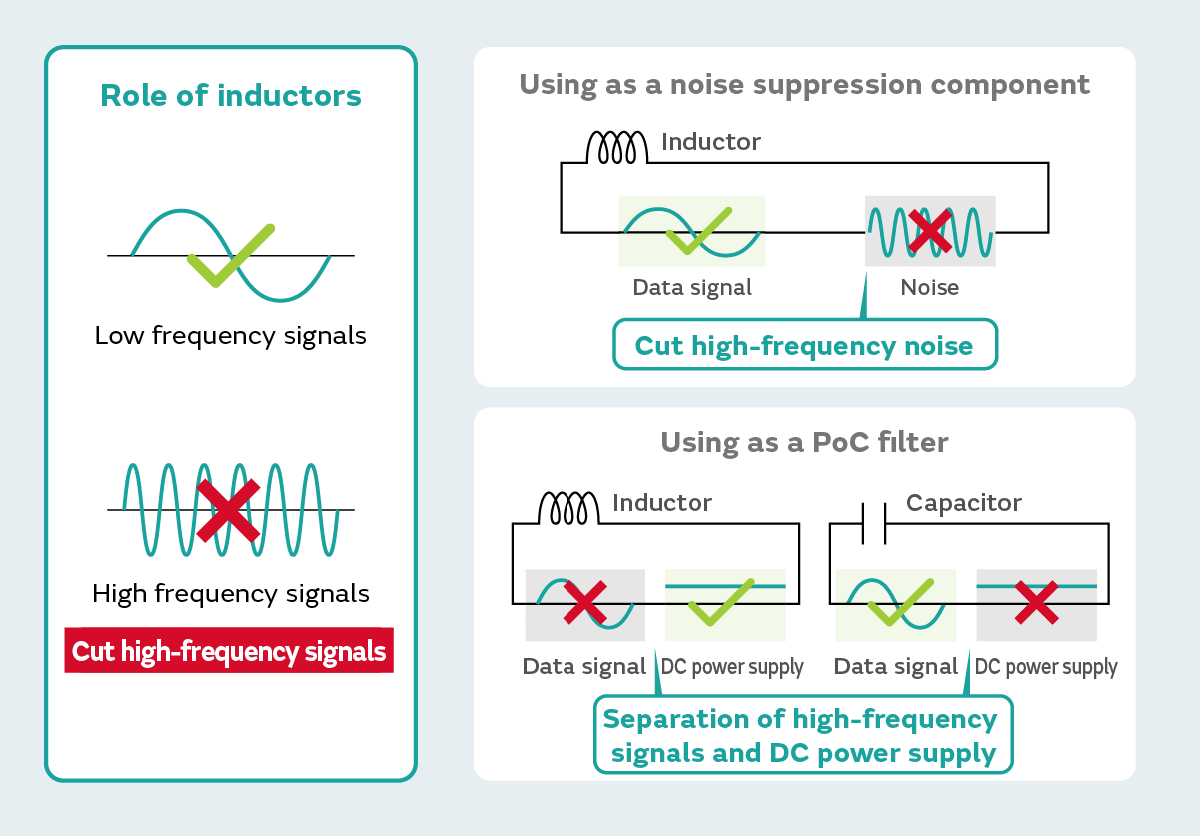

Murata Manufacturing Co., Ltd. ("Murata" below) provides a wide range of different products for driving further advancements in vehicle-mounted networks. Some representative examples of Murata products include its common mode choke coil (CMCC)*4, which is a noise suppression component*3, and Murata's inductor for PoC (Power over Coax)*5, which is a technology that combines a signal line and power supply line into a single line. CMCCs have characteristics that limit the passing of high frequencies, enabling them to be used for removing high-frequency noise. PoC filters are used to separate the AC control signals from the AC control signals and DC power supply that were sent over the same cable so that only the DC power passes through.

*3: Noise suppression components refer to electronic components that absorb and remove unneeded noise that mixes in with the control signals and data handled by networks and computers so that it allows just significant signals to pass through.

*4: A common mode choke coil (CMCC) refers to a filter that uses two coils facing each other to remove common mode noise that is problematic in differential transmissions, balanced transmissions, power supply lines, and audio lines without affecting the signals. Common mode noise is noise generated by fluctuation in the grounding state in current that flows due to small amounts of stray capacitance between the signal transmission path and ground (equipment case, ground surface, etc.). Because this involves the ground, whose status is difficult to monitor, strict preventative measures are required in the transmission path. CMCCs include stacked types, film types, and winding types, but the winding type is used for vehicle-mounted CMCCs because of the high performance requirements.

*5: PoC (Power over Coax) is a technology that integrates the line for data transmission and the line for supplying power that is connected to the vehicle-mounted cameras and other devices for sending both data and power over a single coaxial cable.

To realize CASE era cars where the car functions and structure will be transformed, as an electronic component supplier, Murata is expected to develop and produce products on a timely basis that satisfy technical requirements that are even higher than anything that came before. In addition, because the scale of the electronic control system installed in the car becomes larger, a production system capable of supplying even more products at a stable quality is required. Through the supply of electronic components for smartphones and other consumer devices, Murata has demonstrated its strengths of timely development of compact, high-performance electronic components and its stable mass production capability for high-quality products. These strengths are expected to give Murata a major advantage in its development and supply of vehicle-mounted electronic components to be installed in CASE era cars.

Murata is developing and supplying a wide range of different inductor products that are essential for building an advanced vehicle-mounted network. Technical developments in vehicle-mounted networks are proceeding at a dizzying pace, and these advancements have further accelerated now that the CASE era will soon be upon us. At Murata, we were among the first to develop products compliant with the latest vehicle-mounted network standards, and this has required us to establish a product development and production system capable of supplying the required volume of electronic components with the needed characteristics at the time that they are needed. We asked the Murata engineers who are involved in the development of vehicle-mounted inductor products about their strengths in this field and what they are doing to conduct timely product development in an environment going through major technical innovations.

--What kind of vehicle-mounted inductor products are available from Murata?

Murata offers a comprehensive lineup of inductor products needed for building a vehicle-mounted electronic system, including ferrite beads, CMCCs and other noise suppression components, power supply circuits, inductors for high-frequency circuits, and more.

--For customers in the automobile industry, what advantages arise from Murata having such a wide range of vehicle-mounted inductor products?

In addition to inductor products, Murata also provides a wide range of other vehicle-mounted electronic components such as capacitors and thermistors. One direct advantage is that, if requested, Murata can serve as a one-stop solution to customers by supplying nearly all electronic components needed for a wide range of applications.

Indirectly, Murata also offers the advantage of being among the first to provide effective solutions based on technical trends for car electronic control systems. As a comprehensive supplier of the electronic components that make up the system, Murata has gathered a depth of knowledge about the latest needs for vehicle-mounted systems and will be among the first to develop the products that will be needed in the future.

--Currently, the automobile industry is in the midst of a major transformation. The electronic components installed in the cars of the future will have numerous needs that are different from existing designs I think that it must be absolutely essential to be able to supply the electronic components having the required functions and characteristics on a timely basis when these new needs arise.

That's right. In particular, noise suppression components are essential for increasing the reliability of vehicle-mounted networks, where technical innovations have been quite apparent. Electronic components having the future required characteristics must be available at a stage that is considerably earlier than market launch. Even if an advanced autonomous driving system is completed, we cannot have a situation where noise suppression components are unavailable for installation in actual cars.

--What are the technical trends that must be addressed in noise suppression components for use in vehicle-mounted networks?

The numbers of cameras and sensors installed in cars have risen dramatically as manufacturers have developed more advanced ADAS and the advent of self-driving cars. At the same time, ECUs have been developed with even higher performance, and their data processing capabilities have also improved significantly. As a result, the vehicle-networks that connect cameras and sensors to the computer have been designed with higher speeds, and the number of cables has continued to increase.

This development of vehicle-mounted networks with larger sizes and faster speeds will proceed together with the adoption of new vehicle-mounted network standards. The requirements for noise suppression components in the new vehicle-mounted network standards will be different from previous components, and they will have more variation. Murata will contribute to advancements in vehicle-mounted networks by providing a timely supply of noise suppression components that are compliant with the technical standards of new vehicle-mounted networks as they occur. Also, it is slightly different from the impact of noise suppression components, but PoC inductors, whose use is becoming widespread in vehicle-mounted cameras, are also one product that is helping to drive advancements in vehicle-mounted networks.

--Inductor products such as noise suppression components and PoC filters are electronic components that are absolutely essential for realizing advancements in vehicle networks.

At Murata, we also have another important role. We develop and propose new noise suppression measures and assessment methods for new vehicle-mounted networks to our customers in the automobile industry. Today, the automobile industry has a large number of development proposals where management resources must be invested, such as autonomous driving, electric cars, connectivity, service development, and more. As a result, currently, they do not have the resources to properly deal with noise suppression measures, but Murata has gained a wealth of technical knowledge and expertise in this field. We have built an anechoic chamber inside our company for researching effective noise suppression measures, and we use it to propose and respond to requests from the automobile industry.

--Standardization efforts for vehicle-mounted networks and components are proceeding primarily in Europe and the United States. What does Murata think about the actions taken in those markets for standardization and next-generation technology development, and what steps is Murata taking in response?

The sales office members from Murata's global locations actively participate in the meetings and communications of standardization groups, and they are collecting the latest information. Also, for the preliminary stage, we are developing inductors and noise suppression components needed for applications while coordinating with the semiconductor manufacturers that are the first to develop the vehicle-mounted network ICs for technology that is targeted for standardization.