Noise Suppression Products / EMI Suppression Filters / ESD Protection Devices

Noise Suppression Filter Guide

"If you don't think of the next project, you'll be out of a job!"--Mr. N

Murata led the world with its BLM series that were the first successful chip ferrite beads. In the latter half of the '90s, the product range of the BLM series was steadily expanding and they were becoming increasingly smaller and with higher performance to contribute to improved functionality of sets. We let our egos run wild, saying, "This is it--the invention of the century!" after every great success, such as when we developed a method to form multilayer coil via holes at a high speed in order to minimize costs of high-precision fabrication processes that are essential for downsizing parts. However, I was lucky to have a manager, Mr. N, who said those words at the top. If it were now, we might think, "What a ruthless boss!" But it was about 15 years ago, and I was a hot-blooded engineer in my prime, so instead it instilled within me an uplifting eagerness, and I thought, "I'm going to build a new product with a level of performance yet unseen that nobody can top!"

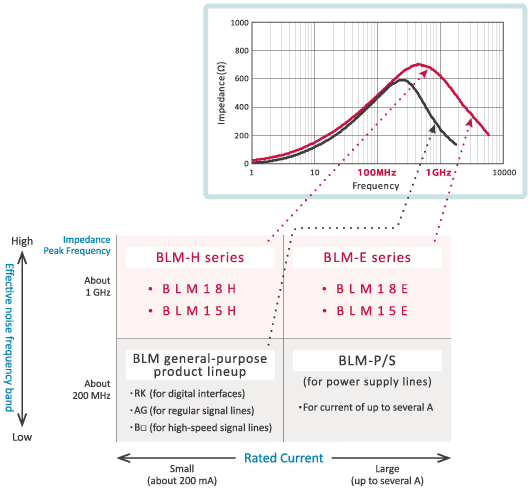

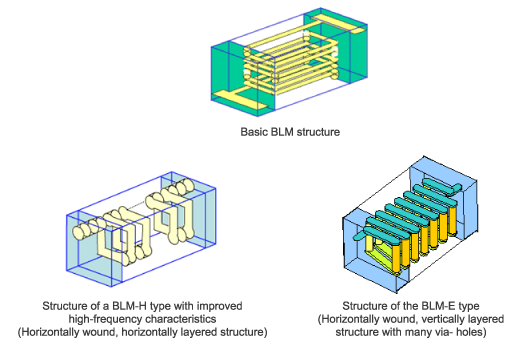

Despite my enthusiasm, I hadn't a clue as to what exactly to do. I continued working on my signature via hole processing, and looked at all the products similar to the BLM in the field. I don't remember when exactly, but at one point I participated in some training somewhere in Murata, and kept a notebook. Based on this notebook, I slowly created a portfolio of characteristics for my future product. I tried categorizing BLM-type products, and created three categories: general-purpose (?) products with impedance characteristic peaks at around 100 MHz and reasonably good coil resistance; products with low impedance but high rated current; and products with excellent impedance characteristics at high frequencies, like the aforementioned BLM-H series. Looking closely at the portfolio I'd made, I realized that there was nothing available in the quadrant of high-rated current at high frequencies. That was it! I zeroed in on that quadrant, and used lots of my signature via holes to create the BLM-E type, with a structure that achieves the same coil arrangement as the BLM-H that is suited to high frequencies, but with a thicker coil pattern. In the BLM-H type, the coil was layered longitudinally along the part, making it impossible to create a particularly thick coil pattern. In the BLM-E structure, via holes constitute the essential part of the coil pattern, making it possible to create a thick coil pattern.

As the saying goes, easier said than done. The prototype production process was a long road filled with twists and turns, great agony, and trial and error. The prototype I finally created was a high-performance BLM with the characteristics we were aiming for--excellent high-frequency characteristics and large-current compatibility--and I was relieved at finally realizing our future livelihood.

The general manager, Mr. K, and I took the finished product and went around visiting the design departments of various companies. At the time, it was the dawn of the DVD recorder era, and I had felt we could get companies to use our product in optical pickups of rewritable DVD recorders, but we couldn't seem to find any who would actually take it. Then, one day, the employee of a company we were visiting finally gave us our chance, saying "Hold on a minute while I go and try this sample out." After waiting for what I remember as not being very long, he came back, and said, "This has very high performance. I've never seen such great noise suppression. I will definitely look into using it!" I was so thrilled I thought I might cry. More than 10 years have passed since that moment, but I can still remember it vividly.

In 2002, just when the design for the BLM-E type was becoming solidified, I joined the BLM-E type product development team. I had been working on the development of another product until then, but I had been interested in trying sheet lamination, which was the main method for fabricating ferrite beads at the time, so I remember being happy to be able to participate in this product development team.

In reality, however, it was quite tough. Due to the unique structure of the product, we faced one challenge after another in printing, laminating, cutting, and other processes, right from the start. "I have never seen this kind of defect" was something we often heard during those days. As the problems were caused by the unique structure, in most cases we could not simply apply past troubleshooting examples from regular multilayer ferrite products. For each problem that arose, we had to work together with people from the production department and other relevant departments to find the cause, throw ideas around, and finally solve the problem. It was a difficult period, but in retrospect, the knowledge and experience we gained through our labors became the foundation not only for stable production of that product, but for design of later compact products to come.

Through the support of many individuals, we finally succeeded in releasing the 1608 (mm) size BLM18E, and the 1005 (mm) size BLM15E the following year.

The BLM-E began with the idea of aiming for a higher rated current area than the conventional high-frequency compatible BLM-H series as well as customer feedback on that idea, and became a unique product created through the unified efforts of the development, production, and sales departments. Keep your eyes open for future products as we continue to develop new BLM series with unique technology.

Persons in charge: Y.T. & I.Y., Component Business Unit, EMI Division, Murata Manufacturing Co., Ltd.

The information presented in this article was current as of the date of publication. Please note that it may differ from the latest information.