Noise Suppression Products / EMI Suppression Filters / ESD Protection Devices

Noise Suppression Filter Guide

With advances in automotive electronics in recent years, car audio and other in-vehicle devices have become increasingly computerized, and more and more vehicles are being equipped with ADAS (Advanced Driver Assistance Systems). As the wireless standards for mounting these devices proliferate and their semiconductors operate at ever-higher frequencies, there is a growing need for components to suppress the conduction noise and radiation noise that is generated.

In addition, as cars become lighter and the devices smaller, there is a growing need for components that are guaranteed to function at temperatures above the 125°C level in the environment close to the engine compartment and in areas susceptible to heat buildup.

As a solution to meet these needs, Murata has introduced high-reliability chip ferrite beads that can be used in environments from -55°C to +150°C.

There are two reasons why ferrite beads are needed for in-vehicle electronic equipment.

Many automotive devices are subject to the CISPR25 noise standard, which is far more stringent than the CISPR22 standard for general electronic equipment, and noise countermeasures for specific frequency bands defined in the standard must be considered.

These frequency bands range from the 150 kHz band, which includes conventional AM radio bands, all the way up to the 6 GHz band, which affects infotainment devices equipped with multiple GHz band wireless capability.

Ferrite beads have noise suppression characteristics (impedance) that cover a range from the FM tuner band, where noise suppression is notoriously difficult, up to the GHz band (Figure 1).

Sensors embedded in vehicles are playing an increasing role in preventing accidents and protecting the global environment.

In order to improve fuel efficiency and reduce emissions of NOx (nitrogen oxide) and other pollutants found in exhaust fumes, the various sensors that monitor engine performance and emissions keep track of parameters such as temperature, flow rate, and pressure, while the Electronic Control Unit (ECU) makes fine adjustments to the running of the engine.

Technologies such as ADAS (Advanced Driver Assistance Systems) and ADS (Automatic Driving Systems), which are deepening the integration of sensor and communication equipment, rely on sensors to keep track of the situation outside the car, such as pedestrians and obstacles, while controlling the steering wheel, brakes, and accelerator.

Everything possible must be done to prevent these critical sensing capabilities from being degraded by noise, which is why there are active ongoing efforts to incorporate ferrite beads into the sensors to improve their resistance to noise.

Murata's chip ferrite beads deliver low cost and small size with a simple structure. They are available in Murata's extensive lineup of EMC (Electro Magnetic Compatibility) noise suppression products (see *1). Ferrite beads are a good choice as a simple and easy countermeasure against noise across multiple frequency bands on a single device. Murata's proprietary design, which reduces materials and stray capacitance (the unintended capacitive component), make these products particularly effective against EMC noise because of their high impedance in the high frequency region above 100 MHz.

*1 Basics of Noise Countermeasures [Lesson 4] Chip ferrite beads

As vehicles grow increasingly dependent on ferrite beads, there is increasing demand for ferrite beads that can withstand temperatures exceeding 125°C. Examples of this demand include the following scenarios:

| ① | To bring down the vehicle's weight, which correlates directly with fuel efficiency, you want to install the Electronic Control Unit (ECU) for the engine and safety systems in the engine compartment (for electro-mechanical integration), but the engine compartment gets extremely hot. | |

| ② | To reduce the size of the Electronic Control Unit (ECU), you are forced to place the ferrite beads close to heat-generating components (semiconductors), where they are susceptible to high temperatures due to heat buildup. | |

| ③ | Since sensors in the engine and exhaust systems will inevitably be exposed to high temperatures, you need to be able handle high temperatures when incorporating ferrite beads into the sensors. |

As a consequence, more and more equipment outside of the engine requires a high temperature guarantee, as illustrated in Figure 2.

Because Murata's automotive chip ferrite beads comply with AEC-Q200, and their unique materials and design technology provide them with high reliability that can withstand even the engine compartment, they can be deployed in any automotive device that complies with the guaranteed temperature range.

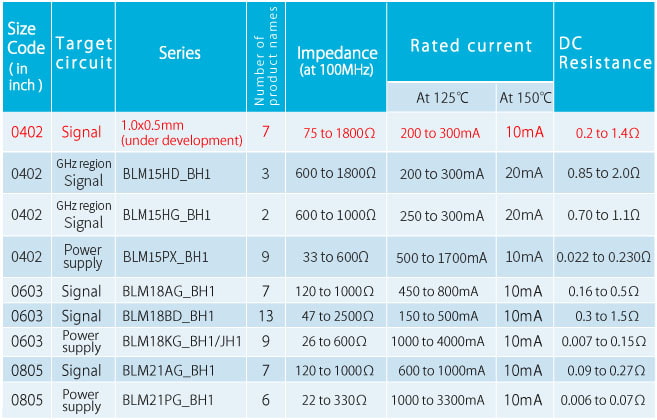

Murata has recently significantly expanded its lineup of 150°C-guaranteed ferrite beads, and you can now choose components for both solder mounting and conductive adhesive mounting. Small components are also under development, and the lineup will continue to expand in the future.

External electrode tin-plated products for solder mounting (AEC-Q200-compatible)

BLM15HD_BH1 series

1005 size: Outstanding high-frequency characteristics, so ideal for noise suppression around 1 GHz

BLM15HG_BH1 series

1005 size: Outstanding high-frequency characteristics, so ideal for noise suppression around 1 GHz

BLM15PX_BH1 series

1005 size: Ideal for noise suppression in power lines

BLM18AG_BH1 series

0603 inch (1608 mm) size/Suitable for noise suppression in a wide frequency band starting from low

frequencies

BLM18BD_BH1 series

0603 inch (1608 mm) size/Suitable for noise suppression in signal lines

BLM18KG_BH1 series

0603 inch (1608 mm)/Low DC resistance, suitable for noise suppression in power lines

BLM18KG_JH1 series

0603 inch (1608 mm)/Handles up to 4A, suitable for noise suppression in power lines

BLM21AG_BH1 series

0805 inch (2012 mm)/Suitable for noise suppression in a wide frequency band starting from low

frequencies

BLM21PG_BH1 series

0805 inch (2012 mm)/Handles up to 3.3A, suitable for noise suppression in power lines

For our 150℃-guaranteed products, a rated current is defined at an ambient temperature of 125℃ or 150℃, and the specifications and reliability are guaranteed in the 150℃ environment (see the derating diagram in Figure 3).

In May 2016, Murata launched the 0603-inch (1608 mm) external electrode tin-plated product for solder mounting, and the 0805-inch (2012 mm) and other sizes are currently in production. In the future, we will continue to expand the lineup with new sizes and target frequency bands, and we will consider the deployment of products with temperature guarantees greater than 150°C (170°C or more).

Tomoki Marui

Product Engineering Section 2, Product Engineering Department, EMI Filter Division

Murata Manufacturing Co., Ltd.

The information presented in this article was current as of the date of publication. Please note that it may differ from the latest information.