Noise Suppression Products / EMI Suppression Filters / ESD Protection Devices

Noise Suppression Filter Guide

It was around the end of fiscal 1995. At a development investigation meeting with the Products Department, we said, "Let's do it. Please let us do it." And with that, we decided to commence development of horizontally wound-type ferrite beads that support GHz frequencies. We initiated the theme the following year with young members in just their second year with the company, and commercialized the world's first "horizontally wound-type ferrite beads that support GHz frequencies" around the end of 1997.

I was assigned to the Ferrite Material Process Division around 28 years ago. At the time, Murata was No. 1 in dielectric ceramic capacitors, but ferrite, which is a magnetic substance, was not a major business. Even within Murata the Ferrite Material Process Division posted consistent losses and was known as a "loser division," which was quite vexing. So everyone in the division felt strongly that we wanted to somehow create a best-selling ferrite product.

There were some domestic companies with a strong ferrite presence at the time, and these companies had already commercialized multilayer coils. Our division had created ferrite cores, but we started with the belief that products manufactured by the layering method also fell under the scope of ceramic products, and were able to release the world's first multilayer ferrite bead products in 1986. After that, we proceeded to expand the series, including the practical application of coil types by via-hole connection, increasing impedances, reducing sizes, and increasing signal speeds by developing new materials. We constantly created products with the intention of quickly presenting new things to the world.

We had had ideas about ferrite beads that support GHz frequencies that are the theme of this column for some time, but had not yet tackled the issue as it looked difficult and expensive. However, from the time we commercialized multilayer ferrite beads, we felt that we wanted to "create something original that did not yet exist, and make our customers happy." And we also felt strongly that we wanted to be No.1. As we investigated the road map together with the Product Planning Division, we were able to start development activities at the perfect timing that matched market demands for high-frequency noise countermeasures.

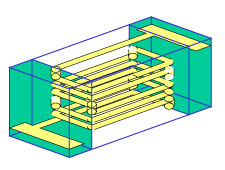

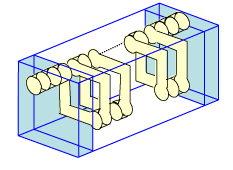

We rotated the layering direction of these ferrite beads by 90° to reduce floating capacitance(*) with the aim of enhancing the impedance at high frequencies. This structure has layers in the lengthwise direction of the chip product, so we named it "horizontally-layered horizontally-wound structure," and called the products "horizontally-wound products." When we started development, issues rooted in this structure and the product features arose one after another, such as stacking offset, cutting deformation, strength, and measurement of high-frequency characteristics. However, we were able to resolve these issues due to group members' tenacious dedication and the enormous cooperation of related divisions.

Murata's ferrite multilayer business was originally small in scale, and the circumstances were such that we were unable to investigate elemental technology from the start by ourselves. We incorporated the technology needed for production from previously developed multilayer capacitors and other sources both in-house and outside the company, fused it successfully with existing core technology, and were able to efficiently commercialize products in conjunction with the development of EMI applications.

Murata is no longer the only company to use this structure, but I think that being the first-adopter produced many benefits. I am also proud that Murata still continues to lead the industry in the multilayer ferrite bead sector, which has many competitors. Amidst recent lower price competition for electronic parts, if you cannot offer good products at low prices, you will quickly be overtaken, and there is fierce competition between many similar products. For this reason, while it is necessary to constantly analyze and compete against other company's products, I think it is also important not to simply copy, but instead to create products with original structures and materials using original methods, and to maintain the mindset of quickly releasing good products that are desired by customers.

* Floating capacitance: Electrostatic capacitance distributed between conductors in circuit elements and circuit patterns, etc.

For example, as the floating capacitance of ferrite beads increases, the impedance drops rapidly at high frequencies, with the result that high-frequency performance is lost as noise reduction elements.

Person in charge: H.T., Product Development Dept. 1, EMI Division

The information presented in this article was current as of the date of publication. Please note that it may differ from the latest information.