“New on-site capabilities” the construction industry is venturing to build through DX (Part 1 of 2)

All kinds of industries have been pointing out the need for “DX (Digital Transformation).” However, DX can be a difficult endeavor depending on the industry, and the construction industry is one where this is true. A lot weighs on the skill and experience of the workforce, and many prerequisites, including technological innovation and the development of the appropriate environment, need to be met before digitalization can be moved forward. Because of this, the digital transformation of the construction industry never really made any headway. It is in these circumstances that an organization called the Japan Construction Information Center aims to use DX to build “new on-site capabilities” to increase the capabilities of construction sites. The organization provides information on public procurement in the construction sector, promotes the utilization and application of information related to field processes, and conducts research and development. We asked Takashi Ozawa, executive director of the Japan Construction Information Center (JACIC), about his thoughts on DX.

Amassing ”Information and Communication Technology (ICT)” engineer know-how and passing it down to the next generation

--We heard that JACIC is working on the DX of the construction industry. From what kind of standpoint did JACIC decide to turn focus to moving DX forward?

The decline of “on-site capabilities” is something that is becoming a big issue in the construction sector. Not only is the engineering workforce aging with the number of engineers on a steep decline, the number of younger workers is also decreasing with the low birth rate. This results in a decrease in the number of skilled engineers and a shortage of workers at construction sites, which means it is becoming difficult to maintain the current on-site skill pools, let alone improve productivity.

In order to turn this situation around, the Japanese government is leading the way in promoting i-Construction*1 to improve construction productivity while also working to increase the appeal of the construction industry. In order to support these efforts made by the government, JACIC is working to use ICT to redesign on-site work with “new on-site capabilities” and improve engineer skill.

When I say “on-site,” I am not only referring to the sites where actual construction work is taking place. I am also referring to sites where other related tasks are taking place, including measurement, inspection, planning, and the maintenance and management of structures after completion. The capability to solve issues that arise in these kinds of sites is what I am referring to as “on-site capabilities.”

A decline in on-site capabilities could have serious consequences, not only resulting in a decline in productivity, but also making it difficult to ensure quality and safety. Issues differ depending on the civil engineering site, which makes it crucial that issues are handled on-site, and therefore testing the engineers’ on-site capabilities. So that we can overcome these on-site issues even as on-site capabilities for solving them are in decline, we are aiming to use ICT to build “new on-site capabilities” that go beyond the capabilities we have had up until this point.

*1 i-Construction: An initiative promoted by the Ministry of Land, Infrastructure, Transport and Tourism to improve the productivity of the construction production system overall by introducing measures such as the complete utilization of ICT at construction sites.

--What exactly are “new on-site capabilities”?

New on-site capabilities are defined as the newly constructed problem-solving capabilities achieved through technological innovation that improve on the capabilities of the people, technology, and systems that have been in place at construction sites up to this point. ICT is exactly the technology that can help us achieve new on-site capabilities. We will make use of different practices that have not been used in the past, such as collection of data that can be of use, analysis through the use of AI technology, project planning using 3D models, and management through the use of virtual space.

For on-site engineers, making use of these technologies will be a new experience, so this would give rise to the development of both technological capabilities and personnel. These new on-site capabilities would eventually take hold and become the standard. Then technological innovations that come in after that will create the next new on-site capabilities. I think technological progress is just a repetition of processes like this.

--So then what kind of DX is JACIC pushing forward? I would also like to ask you about the role of JACIC and its position in the construction and civil engineering industries.

The DX of the construction industry is currently in a transitional phase. Thanks to the promotion of i-Construction, the digitalization of the construction industry has made progress over the past few years.

There is particular focus being put on “BIM/CIM,” Building Information Modeling, and CIM for Construction Information Modeling/Management. BIM and CIM are three-dimensional models of a structure or other object created on a computer. These 3D models are increasingly being used for planning and running simulations before starting on the actual construction work. It was initially BIM, or 3D models used in the construction sector, that became popular. CIM is the application of this concept to civil engineering construction.

JACIC conducts research on and commissions tasks aimed at propagating and promoting work that utilize BIM/CIM. We also handle a wide range of other data like construction-related information with a special focus on information related to public procurement, the results of various construction projects and operations, order history, and cost estimation data.

The DX we are proposing is the use of a cloud system as the environment for seamlessly utilizing and applying every piece of information on a platform. By doing this, we hope to promote the utilization and application of all of the different kinds of data available, from public procurement information to BIM/CIM.

--Can you go into more detail about this DX strategy?

We are still in the development phase, and are preparing to enter the phase of implementation soon. With that said, we have already begun demonstrating some concrete ways to do this.

First of all, in the area of government and public institution procurements, the systems for each of the public procurement processes--from ordering to bidding and contracting--have been used separately up until now. If we were to use cloud computing, however, we would be able to access everything with just one ID. This would provide benefits like the elimination of the need to go through unnecessary duplicate procedures, and improve work efficiency.

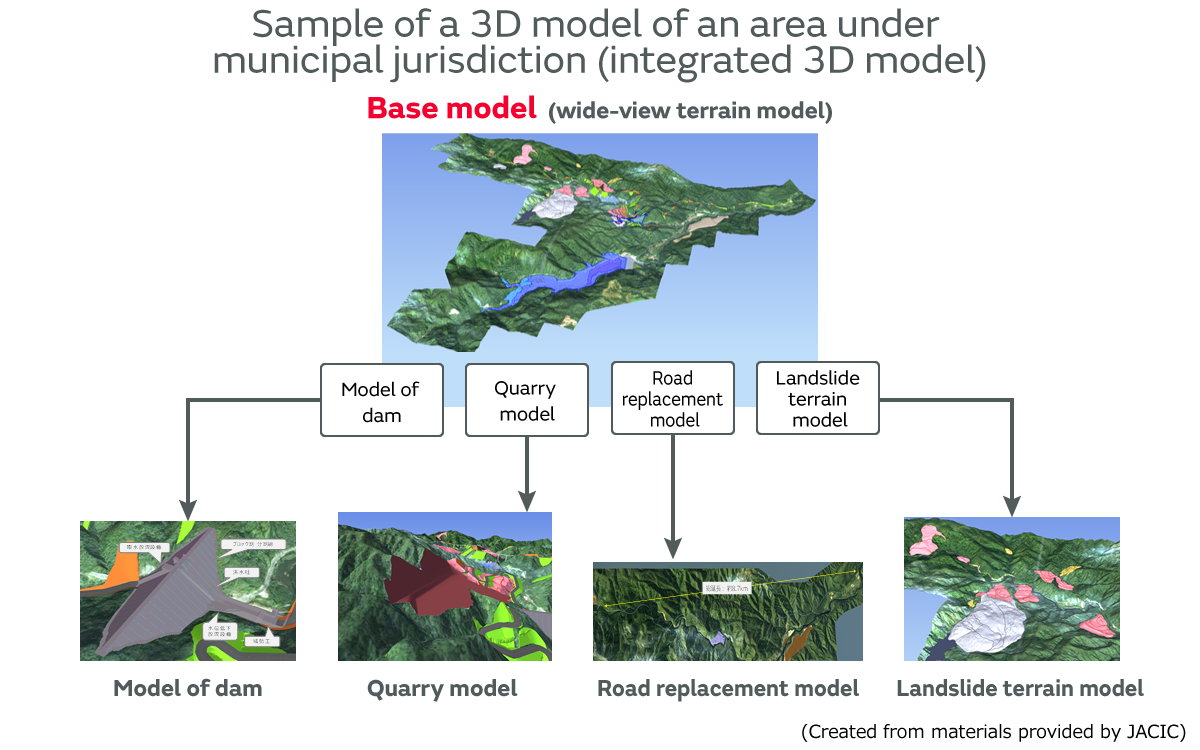

In the same way, we would incorporate cloud computing to construction sites to manage everything from measurement and inspection to preservation management for projects that utilize integrated 3D models. We would build a platform to connect 3D models and all sorts of other data to these integrated 3D models.

For example, if you have a dam construction project, you can click on the target area of the integrated 3D model to see the detailed 3D model of the dam and the construction progress. Additionally, it would be possible to link other necessary data to these models as attributes, such as the types and quantities of materials. This would make it possible to not only use virtual space to improve the efficiency of planning and construction, but also to build consensus among stakeholders.

What’s more, establishing a platform like this would enable us to check and organize the integration of more information more quickly and allow for know-how to be collected and handed down to others.

--What part of this ties in with the handing down of know-how?

Through the building of this integrated 3D model, those working on the project would be able to retain important information and know-how in the system. The integrated 3D model, a repository of information and know-how, could be handed down to those working on the next project. This means that those who receive the hand-me-down model can refer to the setup to see the information that was required by the experienced individuals from the previous project and how they used this information. This information can in turn be used as reference for the project at hand. Information that would be difficult to convey through words can be practically conveyed through models.

The client builds platforms to advance DX

--So platforms are the foundations that enable information sharing and drive DX forward at construction sites.

That’s right. Cloud platforms are actually also useful in terms of disaster response. Construction sites are also important in the maintenance and management of projects after completion, so those in charge must not only be able to gather information on a regular basis, but also right away when disasters such as heavy rains and earthquakes occur. In situations like that, cloud systems would allow for instant access to platforms and instant sharing of information no matter where you are, and multiple people can simultaneously share a screen as they figure out how to handle whatever is at hand. This is a valuable advantage.

--I see. We hear about DX being about digitalizing parts of businesses, such as replacing the analog with their digital counterparts and allowing for remote work, but JACIC’s proposal places the focus on building a platform that seamlessly manages every stage of the construction process.

Currently, all of the different tasks and processes are being digitized, converted into data, and automated. In the construction sector, utilizing models and data from previous processes to advance later processes will lead to an increase in efficiency. This is why it is important to move back and forth between models and data for each work process. Therefore with DX, we will first have to create a platform that can link all of the data and models together seamlessly.

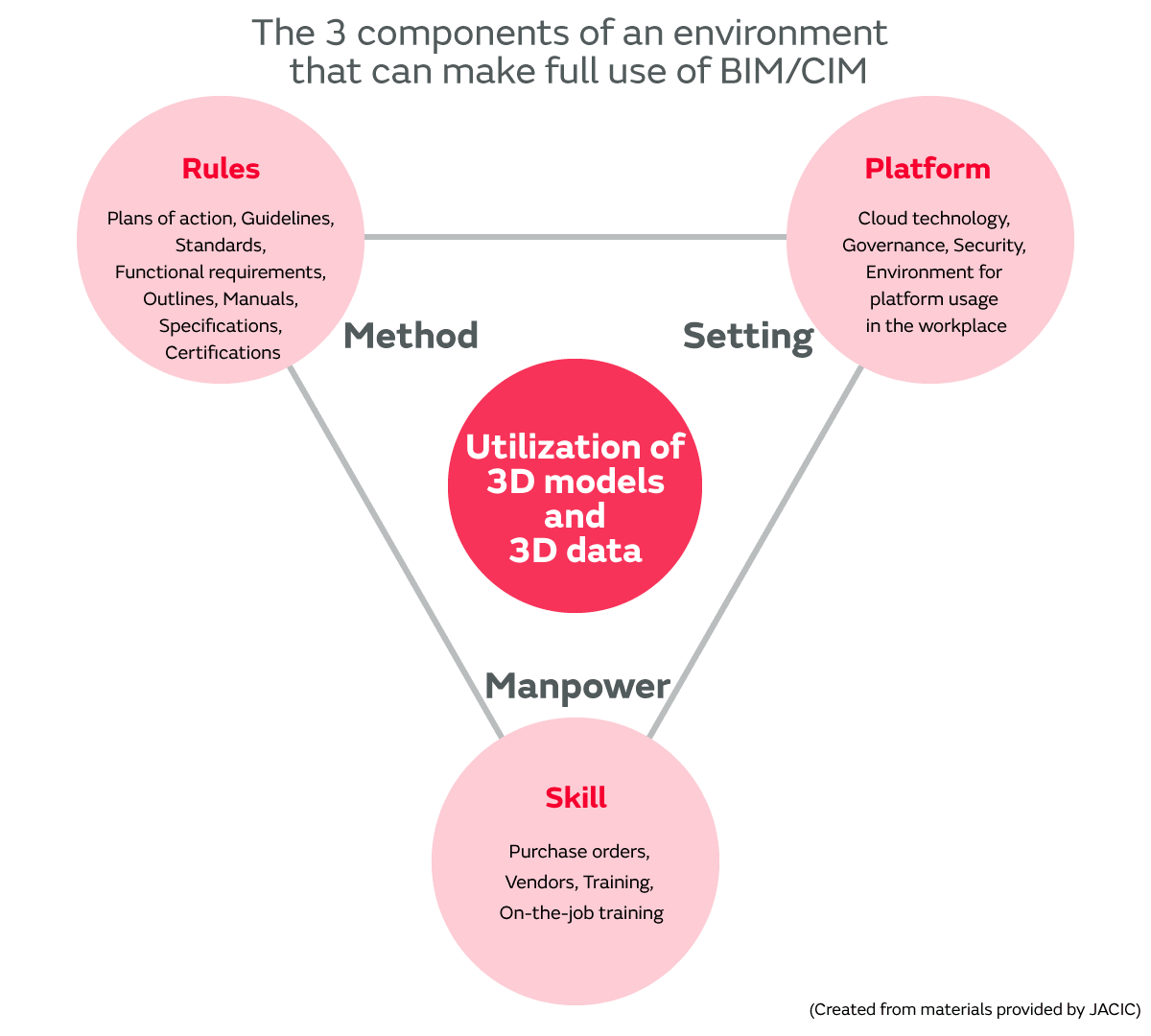

On top of promoting BIM/CIM to push DX forward, we also bring up what we like to call the “3 key components”: “method,” “manpower,” and “setting,” and the idea is to have all three.

The first component is “method,” and this is laying out clear-cut rules for implementation. This means having the plans of action, guidelines, outlines, and manuals ready for a project.

“Manpower” refers to the training of the workforce to become proficient in using ICT. In the early stages, everyone from the ICT beginners to those with some proficiency to those around them who will be able to teach them would have to be identified. Training would then have to be carried out systematically from there.

Finally is “setting.” There needs to be an environment established where BIM/CIM can be fully applied. In our case, this would be our platform. It will be essential for this to be ready before anything else, but this is where some points of caution come in.

--What are these points that require caution?

DX demonstrates its true value through the facilitation of the linkage of models and data collected from the various construction processes. In the case of construction, models and data are seamlessly linked across the processes of measurement, planning, construction, and preservation maintenance. It is from this linkage that the best use of data is derived. The platform is the very foundation for this linkage. In the past, business operators in the construction sector did not build their own platforms. Instead, platforms were prepared by the project contractors. Even now, I’m sure there are still many instances where work is divided vertically.

What is crucial is that the business managers involved in all of the construction processes build a platform that the stakeholders involved in each process can fully utilize. This platform must be linked with the companies and institutions on the vendor side to move DX forward.

In terms of the construction industry, the aim is for the vendor for each task to have its own platform, and for the client to have a platform that is linked to each one of these vendor platforms so that the vendors can likewise access the client platform. Creating the structure for this will be very important in moving DX forward, and I think it will maximize the effectiveness of data utilization and application.

For the DX that JACIC is pushing forward, the outline and the preparation required for the platform that holds the key to this has been figured out. As mentioned in this article, human judgment is essential to work carried out at construction sites. Just how will the roles of people change as DX moves forward? Furthermore, will IoT and other technologies be used to advance the DX of actual on-site operations? In the second part of the article, we will dive deeper and ask about prospects in the New Normal era, and more.

Takashi Ozawa

Executive director of the Japan Construction Information Center Graduated from the Graduate School of Engineering at Kyoto University in 1984 and joined the Ministry of Construction in the same year. In 2002, became the Director of the Takeo River Office of the Kyushu Regional Development Bureau. Served as Counselor of the Secretariat of the Reconstruction Headquarters for the Great East Japan Earthquake in 2011, Deputy Director General of the Cabinet Office, Okinawa General Bureau in 2013, and Deputy Director General of the Cabinet Office in 2015. In 2019, became a council member of the Japan Construction Information Center. In 2020, entered his current position. Ozawa is currently proposing and implementing a variety of ways to further on-site DX and improve on-site capabilities.