“New on-site capabilities” the construction industry is venturing to build through DX (Part 2 of 2)

The DX (digital transformation) of the construction site has long been considered extremely difficult. Taking on this challenge is the Japan Construction Information Center (JACIC), which manages various civil engineering and construction industry information. At the Center, a platform is being built that utilizes cloud computing to provide centralized access to all kinds of information. Nonetheless, construction sites are different from manufacturing plants in that site conditions are more complex, and therefore it can be said that they are difficult areas to digitalize. How should DX proceed in circumstances like this? We continue our interview with JACIC’s Takashi Ozawa.

The “digital twins” required for DX. Where does reality and the digital world meet?

--The DX of each industry has been rapidly picking up pace with the onslaught of the coronavirus pandemic. DX in the civil engineering and construction industries is considered more difficult than the DX of other industries. What is the actual situation at the moment?

The construction industry is promoting i-Construction and DX is being gradually moved forward. With that said, the coronavirus pandemic has made an impact, and with the situation looking to stretch on, we see the need to promptly make headway with DX. So not only do we have to move DX along to replace the traditional ways of working, but we must also fundamentally change the way we work and adopt a way of working that accommodates DX.

One of the major realizations from the coronavirus pandemic is that DX comes with Business Continuity Plan (BCP) support. While it was common to talk about work productivity improvement and BCP separately, DX delivers both. The immediacy and simultaneity of cloud systems can be taken full advantage of, and make it possible to carry out tasks in a low-risk environment. The ICT-based virtual space approach to work would also be beneficial when viruses such as the coronavirus are prevalent. The incorporation of ICT will enhance BCP while increasing productivity. And since we have come to the realization, it is now more than ever our chance to use DX to fundamentally transform the way we work.

--As you also touched on in the first part, the construction industry is primarily centered around working in “real” space. These “real” sites would be susceptible to factors like weather conditions and limitations of the construction sites. What are you placing focus on for the implementation of ICT and digital technology in these areas of the industry?

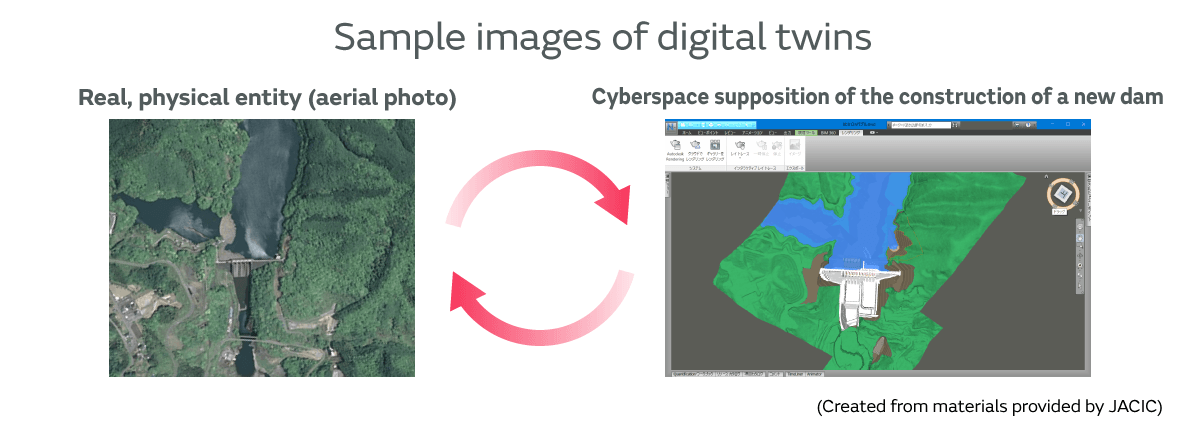

The idea of “digital twins” is key. The “real things” in physical space and their “virtual entity” versions, such as BIM/CIM (see Part 1) 3D models, etc., that exist in cyberspace are considered “twins,” and both are utilized in this approach to carrying out operations and management.

“Virtual entities” have their advantages, such as how they allow for the visualization of areas that would be difficult to visualize with the “real thing,” or allow for things to be tested out in a way that wouldn’t be possible with the “real thing.” For example, with virtual entities, simulations can be done to find out things like the effects of a failure in a certain location or the changes that would occur if the structure of something is changed slightly.

After performing detailed simulations on a virtual entity, we can take what we learned and put it into the real thing. We would also be able to verify the results with the real thing and check the effectiveness. But the thing is, the “real thing” and the “virtual entity” are “twins,” so they both have be made the same way and the consistency of both of their processes has to be considered. Specifically speaking, we create process and procedure manuals for both the real and the virtual entities, and manage them simultaneously. We also use the virtual entity to solve construction and management issues as well as provide the appropriate management appropriate for the real version. This way of working is suited to the use of models and data in the era of DX.

--What exactly do you mean when you say you “use the virtual entity”?

There is something called a cyberphysical system. First off, we use IoT technology, like sensors, to “collect” all kinds of data and values in the physical environment. We bring that data into cyberspace and “amass” it in a cloud system or database. Using all of this data, we do things like run AI analyses or simulations with 3D models in order to “analyze/visualize” the data. We then apply these results back into the physical space and “utilize” what we learned from the virtual version in the management and operation of the “real thing.”

After that, we “collect” the data that results from “utilizing” that information. We repeat this cycle, moving back and forth between the physical and cyber spaces and repeatedly going through the “collection” → “accumulation” → “analysis/visualization” → “utilization” → “collection” work cycle to continue to make improvements.

However, in emergencies, such as in times of disaster response, it becomes necessary to “analyze and visualize” the “collected” data together with the data that has been “accumulated” up until that point to immediately “utilize” the available data for facility operations and disaster countermeasures. Unlike with the manufacturing industry, steadfast response is required of the construction industry. Cloud technology and its immediacy, however, makes this possible.

Implementation of ICT will help engineers get reassigned to where they are needed

--Since we’ve talked about the relationship between “real” and “digital,” we would also like to ask about the balance between human and machine. The use of ICT is moving “manpower reduction” along, but does this mean that there is no longer a need for engineers? How do you think humans (engineers) and ICT should work together?

It is unlikely that engineers will become unnecessary because of the use of ICT. We instead need to be thinking about how to properly “redistribute” engineers and their time. There are many areas where there is a shortage of workers or where further improvements need to be made to technology. If ICT leads to manpower reduction, then we would be able to distribute people and time to the areas where technological expertise is really needed. It would allow us to establish an environment where engineers could fulfill the vital role they are needed to play.

For instance, there are many uncertainties at construction sites, including the topography and climate, which necessitates on-site capabilities. There is a need to increase the number of opportunities where new on-site capabilities can be learned, new on-site experience can be built up, and technological expertise can be brushed up. No matter how advanced AI technology gets, in the end, it is the humans who will be making the decisions from a comprehensive point of view.

Communication with different stakeholders, including making modifications with each associated site and explaining projects to residents, is a major part of the construction industry in every stage of the construction process. This kind of work cannot be left to machines. We want to be able to set aside more manpower and time for those working areas like this where human-to-human communication is required to develop even better communication skills.

--I see. Is the implementation of ICT also making progress for those working at the construction sites? So far in the interview, we have talked about the DX of the management of planning and construction. How is it coming along for the on-site workers?

We have also been making progress with the implementation of ICT for on-site work. In recent years, for example, there has been a push for measures against heatstroke for workers during heat waves. In one case, we distributed wearable devices to workers that keep track of body temperature and heart rate as a measure against heat stroke. The devices would also analyze the outdoor temperature and humidity and give alerts to the workers and managers if the results of the analysis point to potentially dangerous conditions.

There has also been an introduction of wearable devices equipped with GPS and accelerometers. By having workers wear these devices, attention can be brought to accidents right away, such as falls. Abnormal movements can be determined with accelerometers, so alerts can be sounded to inform others to the situation.

While these devices are being used from the perspective of hazard prevention, in the future, the use of wearable devices and IoT technology for the improvement of productivity is also predicted to increase.

--What kinds of things would become possible if the use of wearable devices and IoT technology increases?

If we could analyze the movements of the construction workers using the GPS data, this would increase the efficiency of construction work overall. By analyzing these results together with time, we would be able to figure out the areas where workers congregate at certain periods of time or areas where there is a shortage of workers. These findings can help us improve construction work accordingly.

The point here is that these kinds of improvements made through the implementation of ICT bring many benefits, not just one. If the amount of time required for tasks can be shortened through a use of GPS to analyze the movements of workers, it is likely that the cost of work would also go down. If the amount of time required for tasks is reduced and there is time to spare, this would also reduce the number of mistakes and accidents that occur. This would then inevitably improve the quality of work as well as safety, and lead to overall improvement in quality as a result.

In addition, something we are also anticipating is the implementation of imaging and video technology. In the construction sector, it is still common to be using image data for records and verification purposes. However, in the future, we are considering the use of image and video data as “intelligent” information for uses such as identification and diagnosis. For instance, one such suggested use is creating a 3D model out of image data taken from the sky on a drone to calculate changes in topography and determine risks. Technology for this is actually being developed.

--Please share with us your outlook of the future of DX at construction sites.

I think there will be progress in the use of all kinds of technology, like IoT and AI technology, at construction sites. The most important part of this would be building a foundational platform that allows us to use and apply the wide variety of data available through ICT. Without it, you won’t have the ability to associate and link information you get from all of the data, models, and other systems, making it difficult to achieve true DX.

We hope to be able to build and promote the use of a platform like that for construction sites. Such a platform would allow for all kinds of information--everything from orders and contracts to the use and application of finished projects, and from measurement and inspection information to post-completion preservation management information--to be viewed seamlessly. All of this construction and business information would also be linked together and centrally managed. True data utilization and application are sure to result in this kind of environment. I believe that would be the most important thing to come from DX.

Takashi Ozawa

Executive director of the Japan Construction Information Center Graduated from the Graduate School of Engineering at Kyoto University in 1984 and joined the Ministry of Construction in the same year. In 2002, became the Director of the Takeo River Office of the Kyushu Regional Development Bureau. Served as Counselor of the Secretariat of the Reconstruction Headquarters for the Great East Japan Earthquake in 2011, Deputy Director General of the Cabinet Office, Okinawa General Bureau in 2013, and Deputy Director General of the Cabinet Office in 2015. In 2019, became a council member of the Japan Construction Information Center. In 2020, entered his current position. Ozawa is currently proposing and implementing a variety of ways to further on-site DX and improve on-site capabilities.