IIoT × Post-COVID-19: Exploring COVID-19 Induced Changes at Production Sites

"Contactless" and "avoidance of the 3 Cs" are attracting attention in the “new normal” era

The impact of the novel coronavirus (COVID-19) extends across the entire industrial equipment market, including Industrial Internet of Things (IIoT) devices. According to British research firm Omdia, the average annual growth rate of the industrial automation market in China, known as the "workshop of the world," was 7% in 2018 but fell to 2% in 2019 due to slumping automotive, electrical, and electronic markets. Despite being the quickest in the world to recover from the coronavirus pandemic, China's economic growth is expected to remain low at 2% in 2020 and 2.7% in 2021 due to slowdowns of main users and supply chain disruptions, etc.

However, it has also been pointed out that the coronavirus pandemic may present opportunities. If factory operation rates fall or it becomes difficult to secure workers, this will encourage a shift to production systems that are less dependent on the labor force, and the demand for smart factories that utilize IIoT networks and artificial intelligence (AI) will increase more than ever. In that case, the key words will be "contactless" and "avoidance of the 3 Cs*."

* Closed spaces, Crowded places, Close-contact settings.

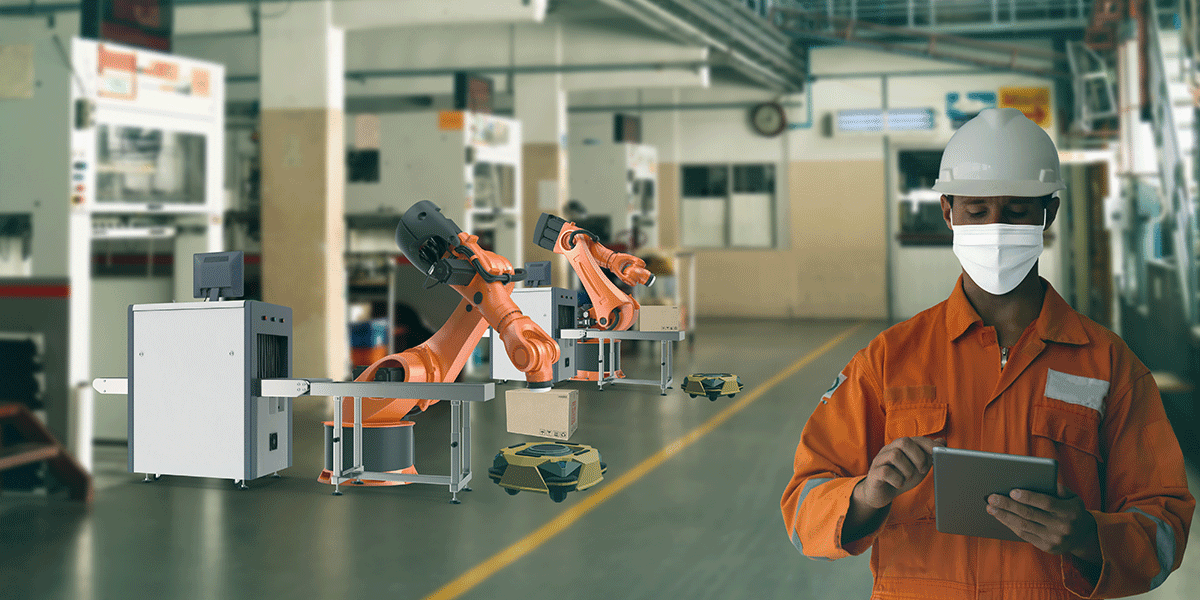

With the coronavirus pandemic, attention on the "contactless" provided by IIoT is increasing day by day. Highlighted possibilities include system control from personal terminals, control by voice and gestures, and non-contact switches. Technology that integrates temperature, humidity, CO2 concentration, human presence, and other sensors into a single package and acquires various data in order to detect and avoid the "3 Cs" has also appeared. Technology that automatically optimizes control so that there is "no need to touch switches" is also being developed for the future new normal era.

According to a report by market research firm Global Information, the global process automation and measurement market is expected to grow by about $10 billion over five years, from $67.4 billion in 2020 to $76.8 billion in 2025. This market growth will likely be further promoted by the future spread of IIoT, needs for energy efficiency and cost reduction, and the growing momentum toward a decarbonized society, etc.

Signs of spreading to AGVs in factories

As part of the trend toward contactless and avoidance of the 3 Cs, automatic guided vehicles (AGVs) are becoming increasingly popular in the manufacturing plant and logistics sectors. AGVs equipped with IoT tags are transport vehicles capable of automatic driving by receiving radio waves from IoT routers installed in the factory. Among the various methods, the natural feature navigation (NFN) method is attracting attention. This type of system uses means such as light detection and ranging technology to create a 2D map of the area surrounding the transport vehicle, which then runs while estimating its own position.

AGVs are divided into four generations by automatic driving method. The 1st generation used magnetic tape, the 2nd generation used QR codes, the 3rd generation used reflectors, and the 4th generation uses the above-mentioned NFN method. 1st through 3rd generation AGVs had issues such as needing to install guides on floors and walls, and requiring changes to the manufacturing process layout for introduction. However, the NFN method simultaneously creates a 2D map of the surrounding area and estimates its own position. This provides advantages such as no need to change existing equipment, and has led to increasing popularity.

Incidentally, the introduction rate for 2nd and later generations is around 50% in European and U.S. AGV markets, but is said to be only around 10% in Japan. Reasons why AGVs and automatic guided forklifts (AGFs) have spread more slowly in Japan than in Europe and the U.S. include many excellent driving technicians in the manufacturing industry and other sectors. However, the use of e-commerce (EC) has expanded dramatically even in Japan due to large stay-at-home demand as a result of the coronavirus pandemic. It is expected that this trend will continue even in the new normal era, labor shortages in logistics warehouses will become serious, and AGVs and AGFs will spread rapidly in the logistics market.

The coronavirus pandemic has brought about major changes in working styles at companies. Just as remote work utilizing networks has expanded, there are also signs of using the coronavirus pandemic as an opportunity for innovation at production sites such as in the manufacturing industry and in logistics. Going forward, the focus will be on how to utilize IIoT for operational efficiency.

Other Links

Related articles

- Technologies and Ideas for Realizing a More Comfortable Society Through Wireless Power Supply (Wireless Power Transfer)

- A Report on Murata Manufacturing's Data Science Case Study Presentations and Corporate Booth - Annual Conference of Japanese Society for Artificial Intelligence, 2024

- Murata Manufacturing Data Scientists Discuss the Power of Practical Application