DX×Murata: The future of manufacturing that is evolving through DX

DX from the Viewpoint of Supply Chain Management

The term supply chain covers everything from the procurement of materials and components used to manufacture products to the delivery of finished products to customers. In a manufacturing business that handles enormous quantities of products and materials every day, supply chain management—managing the supply chain, working to improve efficiency, etc.—is essential. In this article, Koyama, Kishino, and Umeda, three Murata employees involved in efforts to transform the company’s supply chain, explain the current situation of and issues affecting the supply chain as well as the benefits brought by DX.

Murata’s supply chain moves enormous quantities of goods: around 13,000 tons every month.

--To begin, can you provide us with an overview of Murata’s supply chain?

Koyama: “Murata operates 50 production facilities and 57 sales bases globally, and our approximately 50 factories all over the world ship a total of 25,000 items per day. In addition to the route from the factory to the customer via a commercial warehouse, there are other routes through which goods flow, such as routes that bring raw materials from suppliers to factories and routes between factories. These involve a large number of logistics companies implementing transport by air, sea, and truck. The total monthly volume of distribution is around 13,000 tons, with an enormous amount of goods moving from place to place each and every day.”

Kishino: “In the Monozukuri Group, Koyama handles distribution operations such as exports and imports, and I work on business improvement in the supply chain area by promoting the planning, building, and deployment of the necessary systems.”

Umeda: “My job involves promotion of DX company-wide, building organizations, and training personnel to build a next-generation digital infrastructure. I work with my two colleagues on the common goal of creating a next-generation supply chain infrastructure. Moving forward, while engaging in ongoing discussions with business divisions, function divisions, and local staff, we hope to promote efforts to boost competitive value through supply chain transformation.”

The issue of dispersion and division of data makes it difficult to gauge the state of distribution.

--What sorts of issues affect Murata’s supply chain?

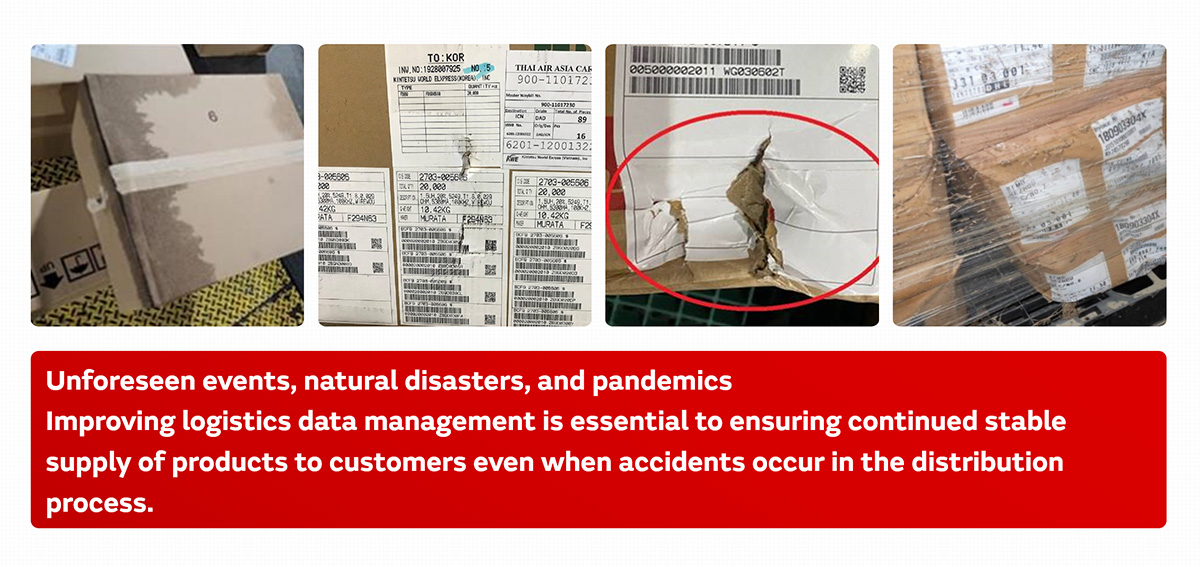

Koyama: “One issue related to distribution is that data is divided among the various processes, and this dispersed data is not linked together. Even when processes were linked, each location maintained its own database. This meant that we had to obtain information from separate logistics companies when we wanted to check the status of outgoing shipments. What’s more, getting an overall view of the situation and tracing progress required obtaining and consolidating data from multiple computing environments, so the work was time-consuming. These issues were brought into sharp relief by the typhoon in September 2018.”

--You’re referring to Typhoon Jebi, which caused widespread power outages in the Kinki and Tokai regions as well as flooding the runways at Kansai International Airport.

Koyama: “Kansai International Airport was Murata’s main export and import hub, and we were scrambling to find alternative routes. Our customers were contacting us with inquiries such as ‘Where is my shipment?’ or ‘When will my order arrive?’, and it took us quite some time to assess the situation and provide answers. This really made us aware of the importance of linking up dispersed and divided data in order to be able to manage the supply chain overall.”

Kishino: “Because of that typhoon I started to think that building a system that would allow us to keep track of where shipments were in a timely manner would also have value because it would strengthen our ability to deal with changes brought on by events such as natural disasters and pandemics.”

The need for innovation to ensure stable supply of products to customers and meet changing requirements

--So supply chain transformation was necessary from the viewpoint of business continuity planning to allow operations to continue in case of an emergency.

Koyama: “But business continuity planning was only one trigger. In recent years, there has been a growing need for business improvement in the distribution area and enhanced flexibility in light of geopolitical risks affecting exports and imports such as pandemics and regional conflicts, as well as the increase in electronic commerce and difficulty of retaining personnel highlighted by the COVID-19 pandemic. More than anything, I really feel that we must carry out a transformation in distribution data management in order to be able to supply our products to customers stably and reliably.”

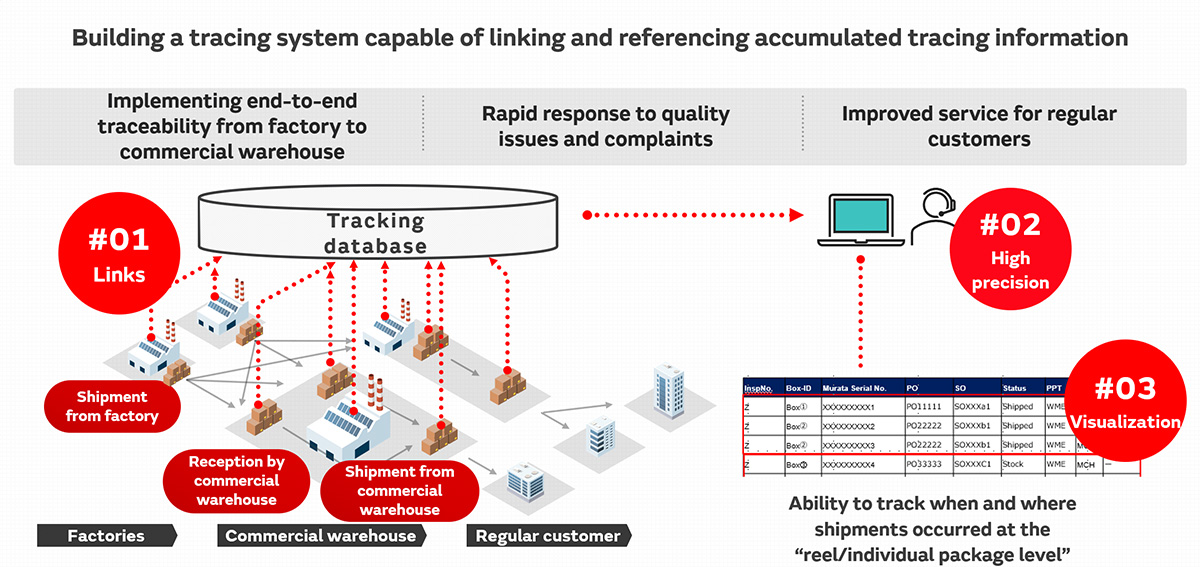

Kishino: “With regard to managing data as Monozukuri becomes more globalized, we are seeing an increase in customers demanding the ability to trace products at the individual package (reel, etc.) level. We can say that to meet these needs, it is essential that we accumulate data from all aspects of the distribution process, from shipment from the factory, to transport, and shipment from the commercial warehouse, and build an end-to-end system that links this data and allows us to utilize it.”

Building a system to enable rapid response to customers and improvements in quality and service

--Can you provide an overview of the system involving tracking databases and shipment trackers?

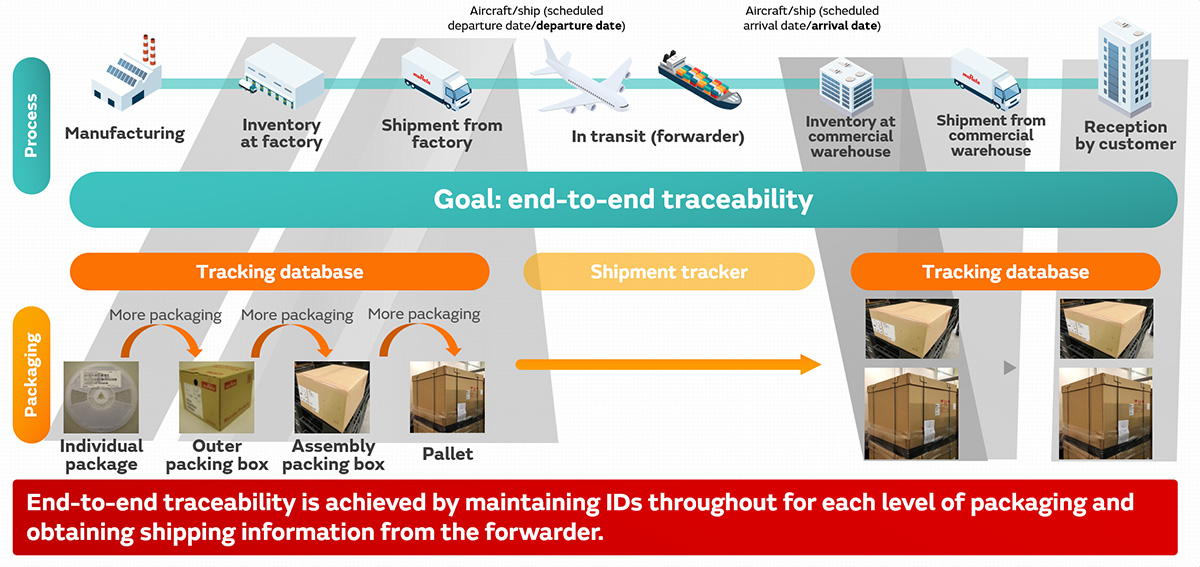

Kishino: “The tracking database that we will release in future is a tool that can accumulate and utilize data at the individual package (reel, etc.) level for all stages of the distribution process, from shipment from the factory to shipment from the commercial warehouse. We have already started to utilize shipment trackers that manage data while goods are being transported by logistics companies, and by linking these systems with tracking databases we can achieve end-to-end traceability.”

--What advantages will the new system bring when it is fully implemented?

Kishino: “First, we will be able to boost the speed of responses to quality issues and complaints as well as improving service for regular customers. Also, by linking data for the various levels of packaging—outer packing boxes, assembly packing boxes, and pallets—data can be utilized and tracing can be performed at any level of packaging, and this will boost productivity by reducing the reception and stocking workload at commercial warehouse and the facilities of regular customers.”

Our digital society makes possible stronger communication and ties between individuals

--Have you encountered difficulties building the system?

Kishino: “We had to impose additional tasks on the commercial warehouses in order to implement tracing at the individual package level. We were able to gain the understanding of the commercial warehouses by painstakingly explaining the goals and value of our efforts to strengthen traceability. When promoting these efforts, I really felt the importance of shared goals and of gaining understanding and cooperation through extensive discussions. There were also many times in our discussions with those concerned when I thought, ‘Maybe linking this data will also make it possible to do such and such.’ In other words, I became aware of insights that might be useful in solving other issues and realized that there is a lot of hidden potential for providing value.”

Umeda: “As Kishino says, linking a wide variety of data has a lot of hidden potential for providing value. On the other hand, as digitization proceeds, some processes and tasks may become harder to visualize, and the problem of some tasks becoming specific only to a limited number of people is emerging. To combat this, we first need to visualize processes and tasks. I think it is important that our digital society makes possible stronger communication and ties between individuals.”

Koyama: “Through this project, I have come to realize that improvements arise from connections between people. I hope we can disseminate a wide variety of information in order to build a new supply chain, and, at the same time, a chain linking people with other people.”

Umeda: “As what we are able to achieve by creating links between data in different places broadens, we are also called upon to make judgments covering a wider area. In response, I think it is important that we establish clear judgment criteria, by setting guidelines, for example, and train personnel capable of making sound judgments.”

Supply chain transformation has hidden potential for innovation in the ways we work

--Finally, what developments do you anticipate moving forward?

Kishino: “We are currently working with the MLCC Division and Battery Division to build and deploy a new production plan creation system. Under the new system, the production plans that individual factories located all over the world previously created using their own individual methods will be replaced by optimized production plans created in a timely manner for related factories, linked by business unit, in order to enable rapid decision-making. Moving forward, the flow of goods and materials as part of the manufacturing process, procurement activities, and provision of distribution resources will be linked in production plans created under the new system. By effectively linking together all aspects of Murata’s supply chain, the aim is to achieve advances through an enhanced ability to adapt to changes alongside better integration of activities.”

Umeda: “Bottlenecks in the value chain can have a negative impact on the process of planning, developing, and designing products. For this reason, I think it is important to maintain close coordination between the supply chain and the engineering chain. Furthermore, I want to work to create and provide value through Murata’s value chain activities, including the demand chain, which is the customers’ product development process.”

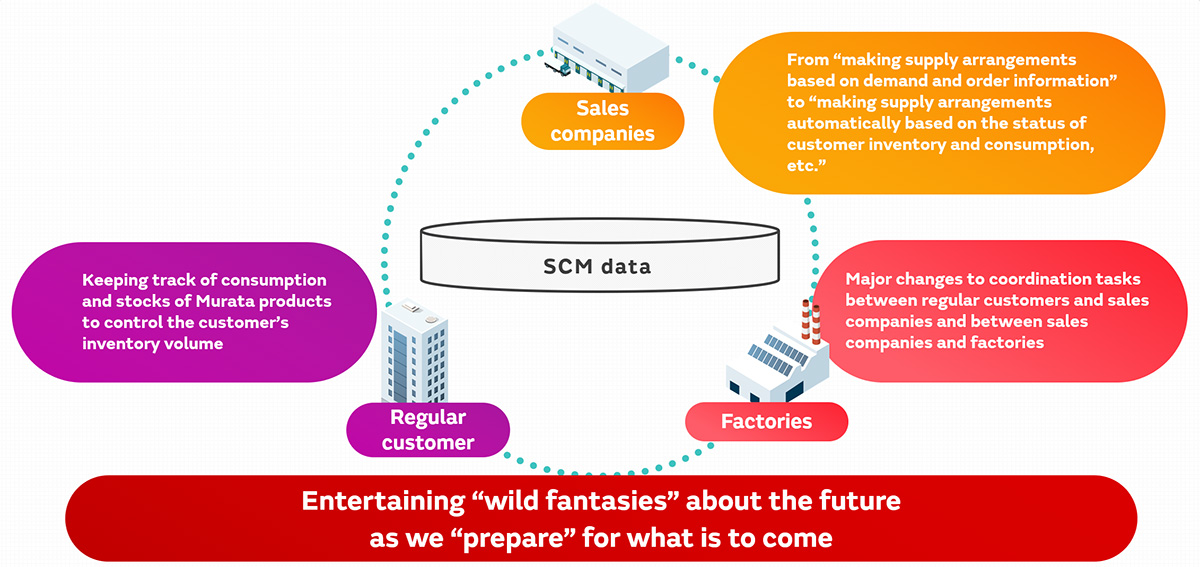

Kishino: “If we can create links with the customers’ data and processes, it will enable Murata to keep track of product consumption and inventory volumes. We may eventually find ourselves in a world where provision of products is arranged automatically, based on the customers’ inventory and consumption status. If this becomes a reality, we may see big changes in tasks that presently take up a lot of time, such as coordinating delivery schedules with customers and coordination between commercial warehouses and factories. The hurdles we must cross are high, but supply chain transformation has enormous hidden potential for innovation in the ways we work.”