DX×Murata: The future of manufacturing that is evolving through DX

Manufacturing DX from the Perspective of CPS Construction

Now that the concept of digitization starting with factories, which is to say, smart factories, has permeated society, the manufacturing industry is starting to shift to digital transformation (DX) that realizes digital reform even more broadly. As part of this, Murata is working to build cyber-physical systems (CPS) that share and perform advanced analysis in cyberspace on data collected and accumulated in the real world (physical space). Goto, who is in charge of CPS construction and who promotes DX in the monozukuri field, talks about the future of the manufacturing industry brought about by DX.

Realizing DX and Meeting Customer Needs

--Murata has been promoting the conversion of factories to smart factories up to now, but please tell us the background that lead to the DX initiative.

Goto: “We have been striving to convert factories to smart factories that utilize AI, the IoT, robotics, and other technologies up to now. However, we are currently shifting to DX that is conscious of innovation and intrinsic value. There was a feeling that tools, systems, and other means had taken the lead. However, this is a process to return to our original purpose and to be aware again of the value provided by DX and the transformation of operations. We are entering a phase of sorting and reviewing while being aware of the movements of other companies.”

--What kind of value can Murata provide through DX?

Goto: “That is something that we should consider for each factory and business issue. In other words, there is no clear definition. However, essentially, I think it is how we respond to the needs of our customers. We will realize the needs of our customers to the greatest possible extent. At the same time, we will eliminate waste and loss in production processes. There is a growing momentum throughout the company to promote kaizen (improvement) viewing these two axes as forms of value.”

What Is Necessary to Build Murata’s Original CPS

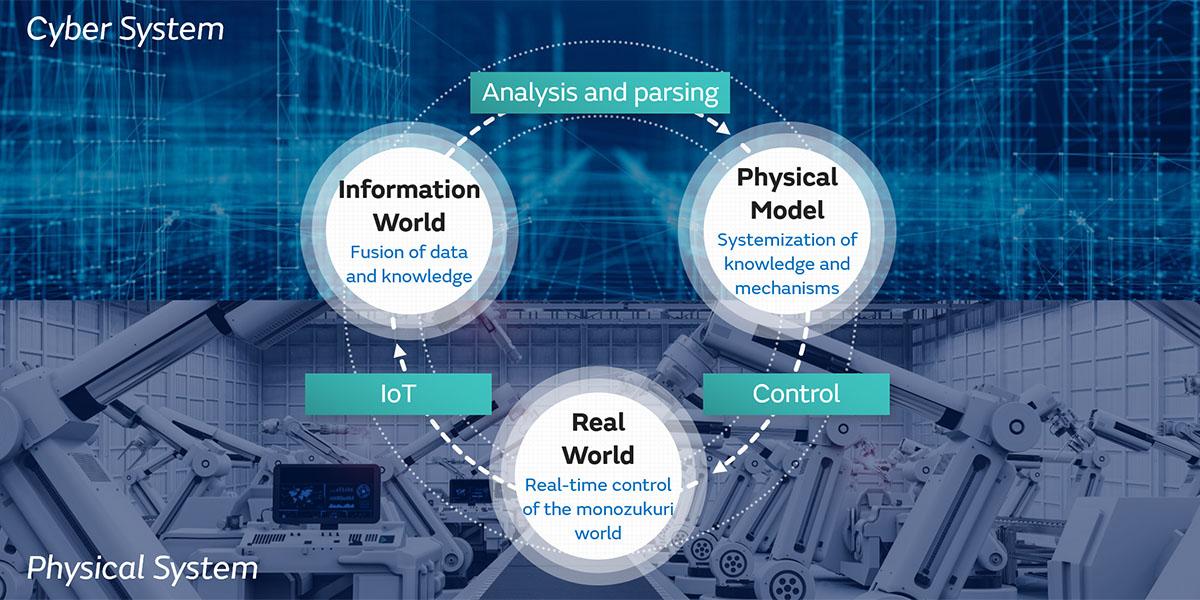

--Please tell us the characteristics of a CPS, which shares and performs advanced analysis in cyberspace on data collected and accumulated in the real world (physical space), in those circumstances.

Goto: “First, Murata values work sites. The capabilities of our work sites are our greatest strength. How can we absorb into cyberspace the technical strengths of personnel at work sites in physical space and then broaden them and make them more advanced? That is the vision that forms the basis of Murata’s CPS.”

--The idea is to reflect the strengths of the physical space into cyberspace rather than what can be done in cyberspace forming the basis, isn’t it?

Goto: “That’s right. A lot of knowledge is formed in-house in vertical integration, which captures added value by performing in-house the flow from materials to the production process and equipment development and manufacturing. That is one of the strengths of our company. In particular, it will become possible for anyone to easily provide high quality by uncovering the keys to product quality controlled at work sites by experienced engineers and then modeling them in cyberspace. Eventually, we will broaden the model even more by connecting it with upstream knowledge to further enhance our strengths. In this way, we are building a CPS that makes even greater use of Murata’s monozukuri strengths.”

The Idea That Machines and Computers Will Do Everything Is Wrong

--How do you plan to develop in the future?

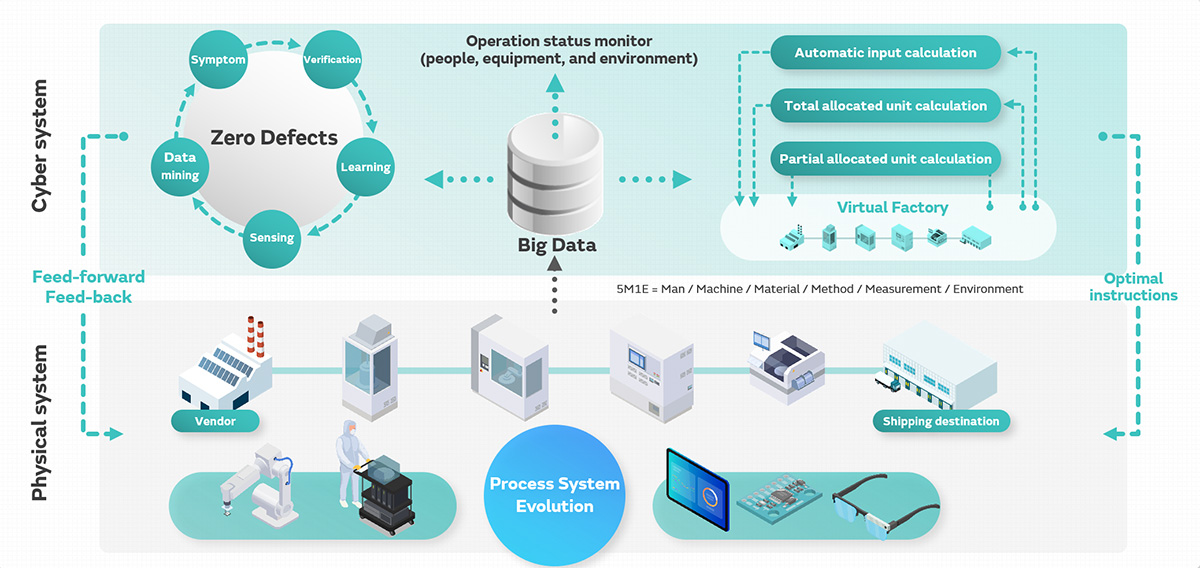

Goto: “We are currently implementing kaizen through DX for each process. However, we will also take on the challenge of attempting to model the range of impact of materials and the process history by connecting processes and reproducing virtual production lines in cyberspace in the future. That will raise the degree of accuracy of the causes and results of defects. At the same time, it may also lead to optimization from the perspective of the processes overall. Moreover, we believe that it will be possible to allow those in development and design to effectively utilize data and monozukuri models generated at manufacturing work sites.”

--What issues have you felt in the initiative so far?

Goto: “Many people tend to think that machines and computers will do everything when they hear the term DX. However, that is wrong. In fact, we will not realize DX without work to uncover and convert into data the areas relied upon up to now by experience and intuition at the hands of humans. Such steady work is a prerequisite to the DX. I believe intrinsic DX will proceed with that.”

DX Begins with Questioning and Thinking

--What do you think about the significance of promoting DX while resolving such issues?

Goto: “There is an extremely high level of social interest in DX. That is to say, it is important that Murata also speedily accomplishes DX starting by providing value to our customers. At the same time, considering the declining population of Japan in the future, it will be difficult to achieve the quantity sought by our customers if we maintain the status quo. Accordingly, we need to change the way we have done things up to now. I think that DX is something we must do when considering the future of Murata for both change and growth.”

--Finally, please tell us the realizations you have come to in the initiative up to now.

Goto: “DX is absolutely necessary for Murata. If you are aware of that, communication with those around you will change and the number of people who think the same way as you do will naturally increase. In that way, it is important for all employees to have an awareness to participate in DX. After that—and I am repeating myself here—DX is steady work. There are many areas that need to be uncovered at the hands of humans. In other words, DX will lead to an increase in the amount of work discovered and thought about at the hands of humans. DX starts with questioning and thinking, ‘Why?’”