Capacitor

Capacitor Guide

Final revision date: 09/13/2023

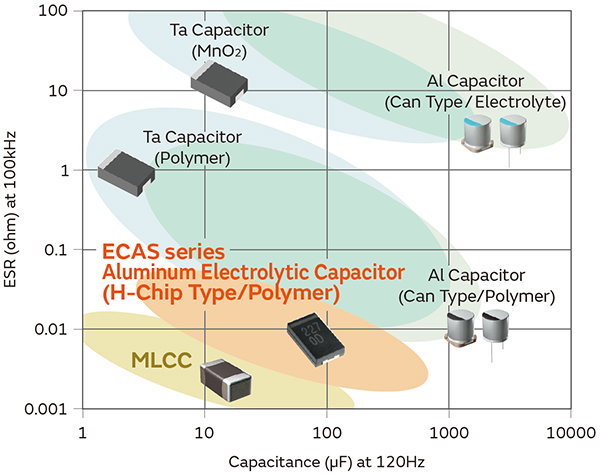

If you take a look at the main board of an electronic device such as a personal computer, you’re likely to see some of the six types of capacitors shown below(Fig. 1). Common types of capacitors include tantalum electrolytic capacitors (MnO2 type and polymer type), aluminum electrolytic capacitors (electrolyte can type, polymer can type, and chip type), and MLCC.

We explain this time about the polymer capacitors (ECAS series) that Murata Manufacturing Co., Ltd. is also working on.

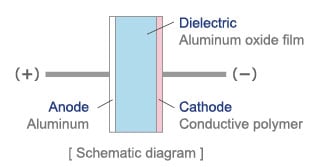

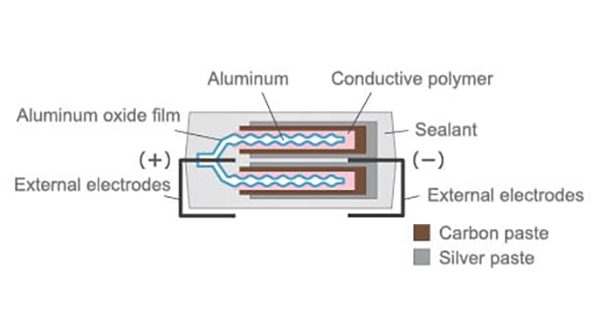

A polymer capacitor is an electrolytic capacitor that uses a conducting polymer (also called a conductive polymer) for its cathode. This is true for both tantalum electrolytic capacitors and aluminum electrolytic capacitors. However, the aluminum electrolytic capacitor uses “aluminum foil” for its anode and a conducting polymer for its cathode.

In contrast, the conducting polymer-type tantalum electrolytic capacitor uses “tantalum metal” for its anode and a conducting polymer for its cathode. Figure 2 shows the schematic diagram of a polymer aluminum electrolytic capacitor.

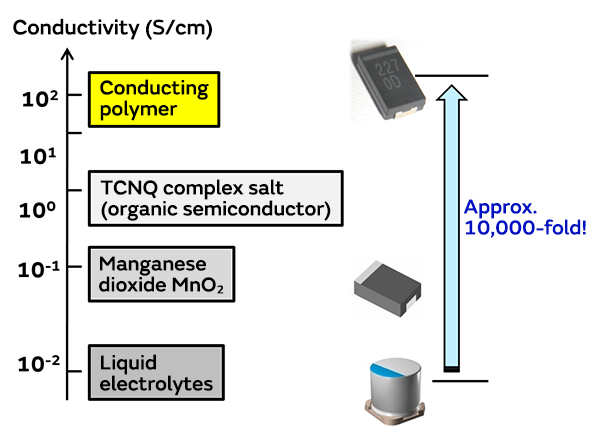

Conventional electrolytic capacitors use liquid electrolytes (electrolytic solution) or manganese dioxide for their cathodes. Using “conductive polymers” as the cathode instead of these can achieve 1. lower ESR, 2. stabler temperature characteristics, 3. higher safety, and 4. longer product lifetime (refer to Figure 1 and Figure 3).

For an electrolytic capacitor, the type of dielectric is generally determined by the type of valve metal used for the anode, and this determines permittivity, DC bias characteristics and acoustic noise characteristics. In this way, various characteristics can be obtained by using combinations of multiple types of materials for anodes, cathodes, and dielectrics. Each material has strong and weak areas, and these must be taken into consideration when designing a circuit for an electronic device.

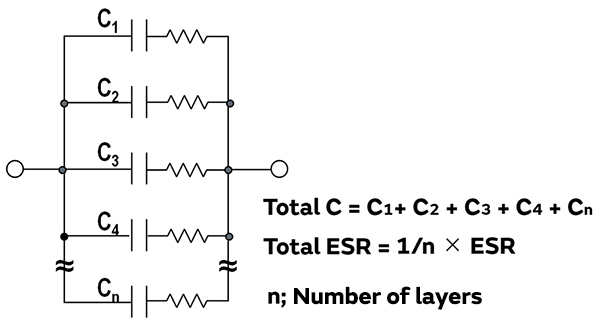

Murata Manufacturing’s polymer aluminum electrolytic capacitors (ECAS series) have the features of low ESR, low impedance, and high capacitance. First of all, “low ESR” means that these have the lowest ESR of all electrolytic capacitors due to using highly conductive conducting polymers for their cathodes in addition to using an aluminum element laminate.

Secondly, “low impedance” means that reduction in an output voltage can be kept to a minimum due to having superior stability against fluctuations on the load side.

Finally, “high capacitance” means that the capacitance can be increased and that the capacitance in actual use when DC voltage is applied is stable since there is no DC bias characteristic of capacitance. The greatest features of ECAS series products are, therefore, their low ESR, low impedance, and high (stable) capacitance.

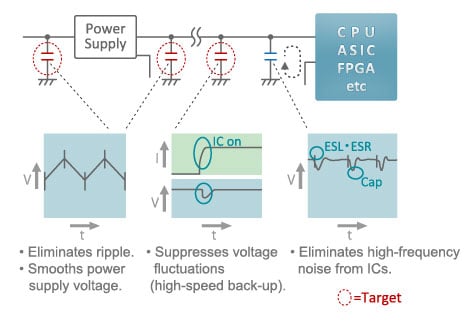

One of the roles performed by the capacitor in a circuit is to stabilize voltage and make it more gradual on the power line.

More advanced electronic devices require even more severe voltage control on the power line (such as for CPUs), and stabilizing this power line requires high capacitance.

One method of resolving this is to install multiple MLCCs. However, Murata Manufacturing has now added the ECAS series to its lineup of MLCC products and can provide solutions that combine MLCCs with ECAS series products to reduce the number of parts and the total cost.

Figure 5 shows the simple circuit diagram of a CPU and FPGA power line.

The ECAS series delivers low ESR, low impedance, and stable capacitance, making it ideal for applications such as smoothing (eliminating ripple and high transient response) various types of power lines subject to large fluctuations in the current load.

Basically, ECAS series capacitors are almost always used in combination with MLCCs, and the ECAS series capacitors really show their value in applications involving suppression of voltage fluctuations (high-speed back-up). Polymer-type tantalum electrolytic capacitors and polymer-type aluminum electrolytic capacitors (can-type) are widely used to suppress voltage fluctuations, but ECAS series capacitors are even more ideally suited for such applications due to their low ESR and good balance between ESR and capacitance.

ECAS series capacitors are widely used in products such as PCs and peripherals (notebook PCs, servers, motherboards, multifunction printers, etc.), and digital AV products (LCD televisions, game consoles, set-top boxes, etc.).

If you are designing the power line for a CPU, we recommend the ECAS series.

Click the following link for a detailed listing of the product lineup.

Produced by: Chemical Device Product Department, Murata Manufacturing Co., Ltd.