SDGs×Murata

Murata Promotes Climate Change Measures – Kanazu Murata Manufacturing, The Road to a 100% Renewable Energy Plant (Part 2) –

INDEX

3. Controlling the amount of electric power with our own energy management system

4. Aiming for a new form of manufacturing that combines climate change measures

3. Controlling the amount of electric power with our own energy management system

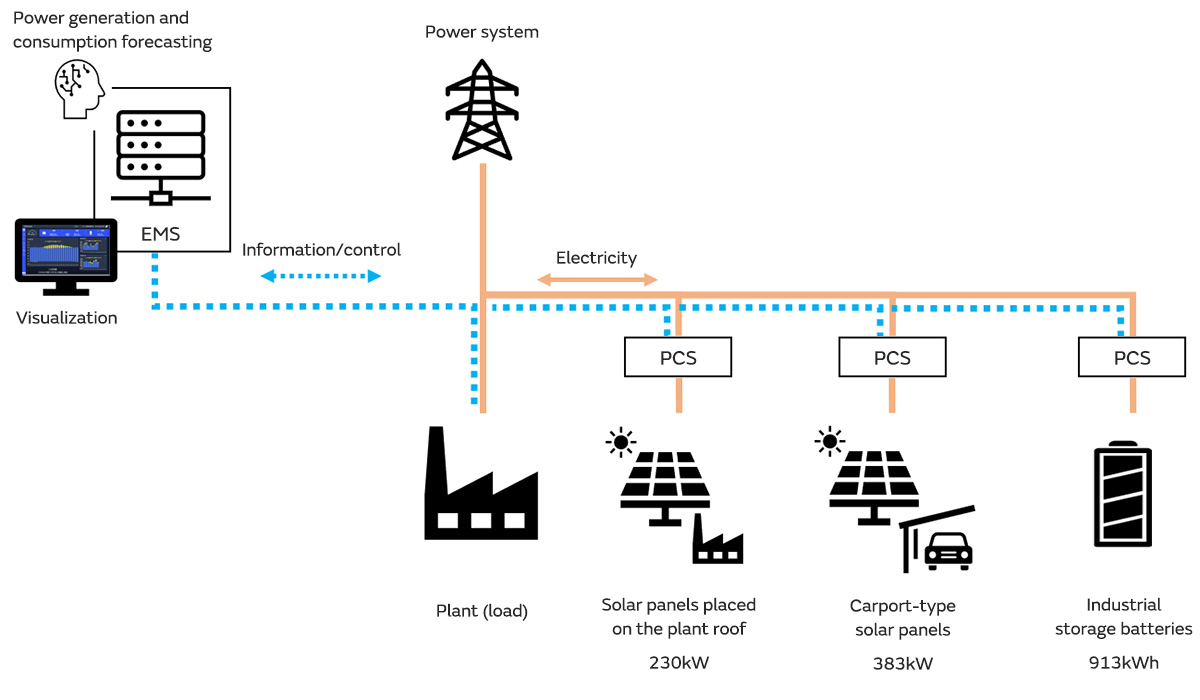

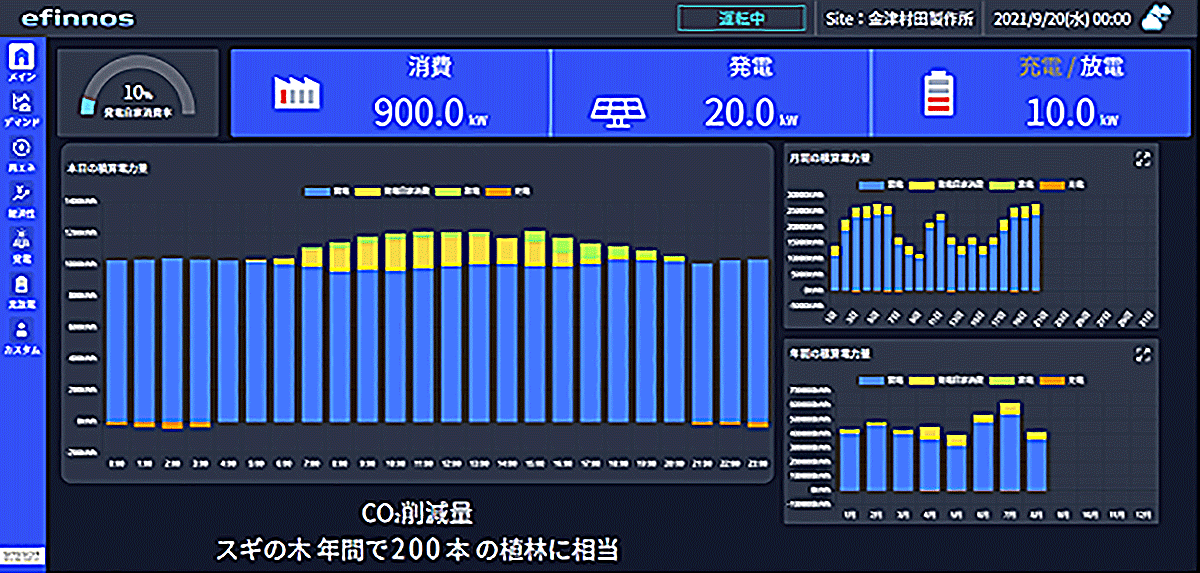

The climate change measures of Kanazu Murata Manufacturing include utilizing solar power generation and a storage battery system. The project, which had scaled up to a company-wide scope, accelerated for the purpose of achieving the initial target of a 100% renewable energy plant. A significant feature of the project that started operation in September 2021 is Murata's own energy management system (EMS).

Mukai: “We had experience developing a battery energy storage EMS for home use, but industrial use was a different objective, so it was newly developed for the most part. The primary objective of this EMS was to increase the utilization rate of renewable energy. In the conventional FIT-type of solar power generation, we were able to send extra power back into the electric power system. However, in this project we aimed to store the power that was generated in-house in a storage battery system and use all of it in the plant without any waste. In other words, if too much power was generated, it would be wasted, and if too little power was generated, then the utilization rate of renewable energy would not increase. This was the number one issue.”

The EMS was used to solve that issue.

Mukai: “The EMS is in charge of control so that the system does not produce electricity peaks. Therefore, AI (Artificial Intelligence) was introduced into the EMS to predict the amount of electricity generated by solar power generation and the amount of electricity to be used on the following day. Because it is solar power generation, the weather is a forecasting parameter, and it must be based on the operating conditions of the plant. If the amount of electricity to be used on the following day is low, then the storage batteries can be emptied with the surplus power put in storage. If the amount of electricity to be used is high, then the storage batteries are charged, and the surplus power is discharged. It is a question of storing electricity or discharging it. Murata built the EMS while determining our own standards.”

The ratio of in-house power generation and captive consumption is 13% with the solar power generation and storage battery system. The question of how to procure the remaining 87% worth of renewable energy was a problem.

Sakai: “I repeatedly consulted with Katsuma and his colleagues in the Environment Department and briefly focused on using the J-Credit Scheme (a system whereby the Japanese government certifies the amount of greenhouse gas emissions that are reduced or removed as credits) for a time. At that time, I learned that we could procure the green power (power created with renewable energy) from the power companies and entered into discussions with them.”

Mukai: “As for the power companies, it seemed that there was no precedent for connecting a captive consumption type of solar power plus storage batteries at this scale to the electric grid, so we held repeated exchanges with them, including discussions about the green power contract.”

While clearing various issues and problems, Kanazu Murata Manufacturing became the first Murata plant to achieve 100% renewable energy through the procurement of green power and in-house power generation and captive consumption through a solar power generation and a storage battery system in November 2021.

Shimizu: “As a Murata plant that is a member of RE100, we aimed to become a 100% renewable energy plant from the beginning. To be honest, I thought that it would take until around 2030, but we were able to achieve it in a faster manner than I imagined. With the support and backing of the New Business Development Division and the Environment Department, I believe that this project was achieved precisely because it was ‘company-wide.’”

4. Aiming for a new form of manufacturing that combines climate change measures

Becoming the first 100% renewable energy plant within Murata had a huge impact on Kanazu Murata Manufacturing.

Shimizu: “It was covered by various media outlets, and we were also contacted by local citizens. In organizational evaluation surveys as well, employees said that ‘they were proud of the plant where they worked’ and ‘their motivation increased,’ which increased their sense of belonging and had the effect of increasing motivation.”

Sakai: “When soliciting designs for the illustration depicted on the outdoor battery energy storage system, we received ideas from more than 80% of the employees. I believe that incorporating an element of employee participation in a climate change measure project significantly changed their awareness.”

Shimizu: “In the past, we rarely thought about things in terms of the environment, and our perspective was only about ‘Will this have a negative impact on the environment?’ Now, we think about things in terms of ‘How much will this contribute to the environment?’ or ‘How much of a positive impact will this have on the local community?’ and this perspective has sprung up among the employees.”

Furthermore, the three core members who promoted the project also made various realizations that will connect to the future.

Mukai: “We are currently considering ways to deploy the EMS and other solutions developed in this project as new businesses outside the company. It is believed that control technologies based on weather, electric power generation, and usage will become a major weapon. In the sense that a future path has been opened up, this project became a truly great experience. There were many parts of this project that required arrangements and explanations to power companies and contractors, etc. In addition, I was also able to get involved in many detailed aspects such as obtaining fire safety permissions when installing the storage battery system, so I hope to apply those experiences going forward.”

Sakai: “As Katsuma and Fujiwara from the Environment Department already mentioned, I realized the importance of management decisions and the speed of decision-making through this project. I think that the decision-making capacity of top management and the stance of incorporating the ideas of front-line workers are essential to promoting projects. The plant manager of Kanazu Murata Manufacturing holds strong convictions and passion with respect to climate change measures, accepted various ideas, and encouraged people. I believe that the fact that we now have a 100% renewable energy plant is due in large part to the decisions by the plant manager.”

Shimizu: “This also ties into a continuous cycle of social value and economic value that is the group's growth strategy, and I realized that the question of whether climate change measures should be captured as a cost or as a value is an important perspective. When captured as a cost, the discussion inevitably turns to cost effectiveness and efficiency, but the perspective changes considerably when it is captured as a value. For example, I believe that climate change measures are a ‘source that creates new forms of value’ such as increasing motivation and cultivating a sense of belonging among employees as well as enhancing plant competitiveness and presence. I hope to use this recent climate change measure initiative as an opportunity to utilize the know-how and technical skills cultivated through manufacturing thus far to make further contributions to realizing an abundant society.”

Other Links

- Kanazu Murata Manufacturing's Plant Set to Operate on 100 percent Renewable Energy- Reducing the load on social infrastructure by deploying the largest storage battery system in the Hokuriku region -

- Murata and the Environment

- Murata participation in Global Environmental Initiative RE100- Aiming for 100% renewable energy use by 2050 -

Related articles

- Scope 3 Category 4 Reduction Measures - Taking On the Challenge to Both Increase Environmental Value and Reduce Costs Through Logistics and Packaging

- The GHG Protocol: Scope 1, 2, and 3 GHG Emission Reductions Companies Must Reach to Achieve Carbon Neutrality

- Murata Promotes Climate Change Measures – Kanazu Murata Manufacturing, The Road to a 100% Renewable Energy Plant (Part 1) –