TVS Diodes (ESD Protection Devices)

Static electricity is a source of trouble in winter when the air is dry in some countries and regions. Static electricity refers to electricity that is literally static; that is, it is electricity whereby the electric charges*1 do not move and the state of electrification*2 is maintained.

High voltages of several kV may be generated between a person charged with electricity by the friction of clothing or another reason and an object not charged with electricity. At that time, if that person touches or approaches that object, a discharge occurs in which the electrified charges instantly flow to the object. This static electricity phenomenon is called electrostatic discharge (ESD)*3.

In addition, the polarities (positive/negative) of the electric charges of objects charged with electricity repel each other if they are the same and attract each other if they are different. In the latter case, that may also cause unnecessary dust, dirt, and other elements to adhere to the product.

Below are typical troubles due to this static electricity and also examples relating to the effective utilization of static electricity.

*1 Electric charges: Electricity is one of the properties inherent to matter. The source of that electricity is called the electric charge. Electric charges have two types of polarity: positive and negative. Various electrical phenomena are induced by the behavior and conduct of these electric charges.

*2 Electrification: For example, when insulators, substances for which it is difficult for electric charges to move and difficult for the current to flow, are brought into close contact with each other and rubbed together, it may lead to a state in which there are many positive or negative electric charges in one of those insulators. This state in which electric charges have accumulated in this way (the state of carrying electricity) is called electrification.

*3 Electric charges move in all instances of discharge including ESD; that is, the current flows. Therefore, it seems that ESD is not a static electricity phenomenon. However, given that ESD is instantaneous and the current is also very small, we will consider ESD to be within the range of static electricity phenomena here.

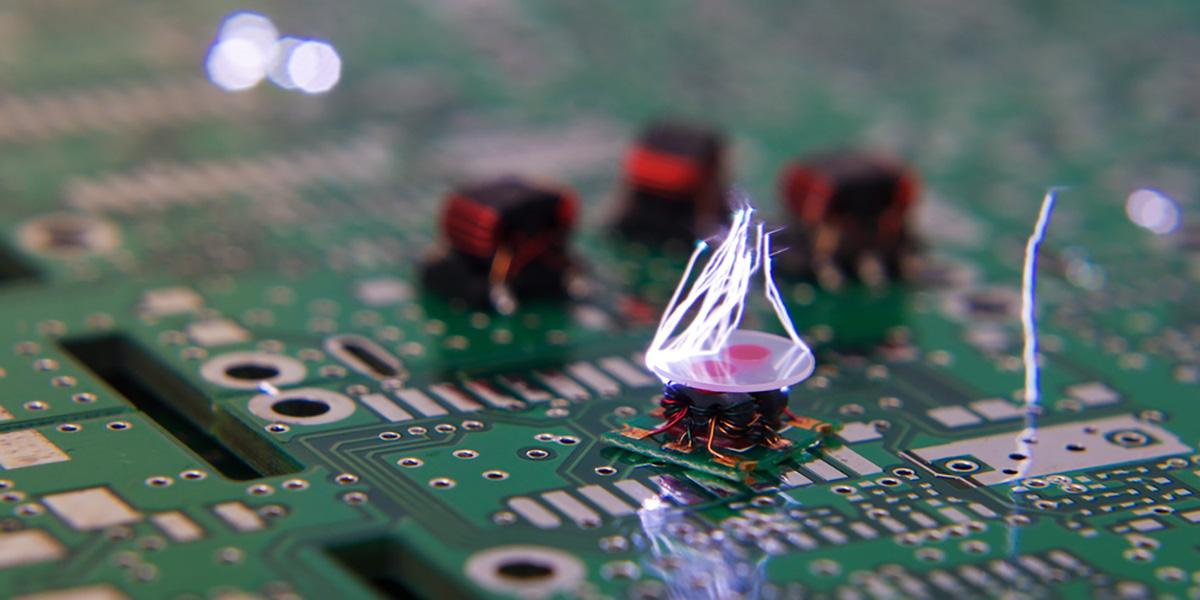

If ESD occurs in ICs and other electronic devices, it may cause electronic equipment to fail or malfunction. When a momentary discharge under a high voltage occurs in an electronic device and causes it to stop functioning, it is called “ESD damage.” This may cause failures and defects not only in the process of manufacturing electronic products but also when they are used by those who purchase them.

Moreover, clothing and other similar items are especially susceptible to electrification and ESD from friction. For example, a worker charged with electricity at a manufacturing site may sustain stress such as irritation and pain to his or her skin by touching products. Furthermore, products may become defective due to ESD damage from workers charged with electricity (Photo 1).

When dust, dirt, metal powder, or other foreign substances in the air and workpieces*4 and products become charged with electricity positively and negatively or negatively and positively, respectively, an attractive force acts between the two as mentioned above. The foreign substance then adheres to the latter.

For instance, if a foreign substance adheres to the housing, car body, or other part of metal (conductor) equipment, it may lead to a deterioration in the paint quality. Moreover, products such as resin (insulator) films or sheets and containers may become defective due to foreign substances adhering to them. Products may also become dirty while being stored due to the adhesion of small foreign substances. That may lead to a deterioration in quality and complaints. Furthermore, if the base material gets twisted or if the corners get turned up in the process of manufacturing and processing a thin film product, it may cause a defect during the process of applying the chemicals and liquid materials that form the paint coating and during the winding of the rolls (Photo 2).

*4 Workpiece: This is the object to be processed in a manufacturing process. For example, the press material is called the workpiece in a process to press-mold metal housing, whereas the housing itself is called the workpiece in the process to paint that housing.

As mentioned earlier, static electricity causes troubles in various industrial products and people’s lives in winter when the air is dry. Besides that, the buildup of snow on solar panels in cold regions significantly reduces the efficiency of solar power generation. That can become a big problem when coupled with an increase in demand for electric power resulting from the use of heating.

It was believed that static electricity only caused such issues and problems. However, research is also being conducted on energy harvesting*5 using static electricity generated by snowfall.

*5 Energy harvesting: This refers to power generation technology that harvests energy from the daily environment (heat, sunlight, artificial lighting, and vibrations arising from human movement or machine operation, etc.) and converts it into electrical energy.

For instance, a research team in the U.S. is researching and developing a device that obtains electric power from the static electricity generated by contact or friction with snow. It is known that snow is charged with electricity positively in a certain temperature range. Voltage is generated when snow charged with electricity positively and an object charged with electricity negatively come into close contact or sliding due to touching and friction. Based on this principle, the research team has successfully realized energy harvesting using snow and obtained electric power from this device. It is expected that this device will be used in a wide range of applications because it is thin, light, and has excellent flexibility.

Functional outfits designed to protect from the cold have been given as an example of the application of this technology. Power can be generated by attaching the device to the surface of clothing or the soles of shoes. It is then possible to heat your body with a heater or to sense your movements and physical condition in outdoor activities in snowfall such as winter sports. This can be done without using secondary batteries or other parts that have been charged in advance (Photo 4).

Moreover, it is thought it will become easier to install and operate meteorological observation equipment in places where it is difficult to supply power by adopting this mechanism that enables sensing by the device itself.

Based on such new ideas, research and development on energy harvesting is diversifying and advancing, thereby increasing expectations for a future in which the number of new options to acquire energy will increase.

In addition to being utilized in energy harvesting and other applications as above, static electricity is being used in printers, copy machines, dust collectors, a variety of manufacturing and processing equipment, and other products. Nevertheless, we can say that there is a stronger impression of static electricity causing troubles such as in terms of ESD damage and foreign substance adhesion as mentioned at the beginning of this article than of it having beneficial uses like this. We have to thoroughly take various measures going forward to avoid such troubles. We introduce here some specific examples of measures against those problems.

It is well-known that electrification arising from friction (frictional electrification) due to an object being moved or people moving is the cause of electrified electricity; that is, static electricity. This electrification also frequently occurs in the process of manufacturing products. The use of static eliminators is given as a typical measure against static electricity troubles caused by those. These static eliminators neutralize electrified charges such as by blowing ions with air onto the target object.

There are various forms of static eliminators. One is a bar type that neutralizes and eliminates static electricity in workpieces charged with electricity on conveyance lines and other systems. Another is a blower type equipped with a fan that neutralizes the static electricity generated during assembly processes involving manual work and other similar processes. Yet another is the gun type that removes foreign substances adhering to an object due to static electricity by eliminating the static electricity while intensively blowing air on a targeted spot.

In addition, wearing a wristband to release static electricity to the ground (GND) to prevent ESD occurring from workers’ hands is a basic measure to prevent defective products due to ESD damage from humans (Photo 5).

ESD and other static electricity issues in pieces of electronic equipment can occur not only in the process of manufacturing them but also when they are used by those who purchase them. For example, if ESD occurs in an IC or other electronic device in electronic equipment when operating a switch or at another time, it may lead to it malfunctioning or failing due to ESD damage. Therefore, measures against static electricity and measures against ESD are required in the design stage.

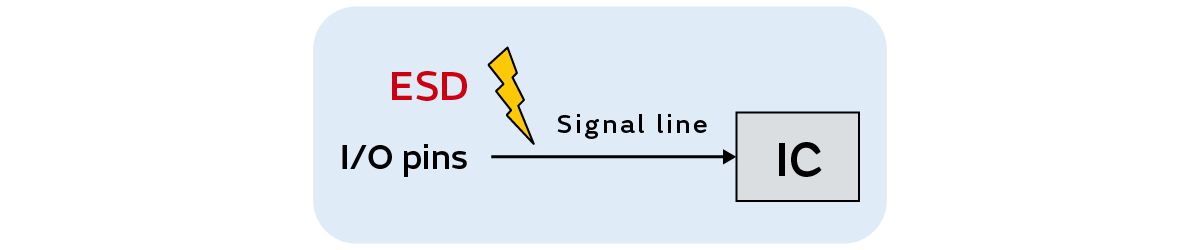

ESD is especially liable to occur at points that are operated by people by hand in electronic equipment when it is being used. Those points include various external interfaces in which buttons, USBs, and other plugs are inserted into and removed from connectors. In other words, the risk of electronic equipment failing or malfunctioning increases when ESD occurs because a high voltage is momentarily applied to an IC while it is being operated (Fig. 1). Accordingly, it is no exaggeration to say that the points that require measures against ESD in electronic equipment are those that the user touches or approaches.

It is necessary to release electrified charges to the ground (GND) to prevent the ESD issues which occur in this way. A device that achieves this is called an “ESD protection device.” We can say that this is a device essential for the stable operation of electronic equipment by preventing sudden failures and other troubles.

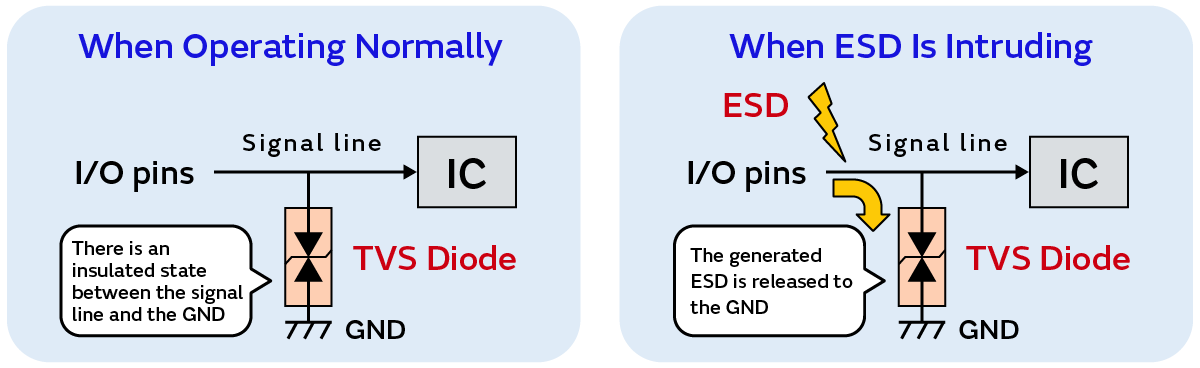

TVS diodes are one of the leading ESD protection devices used in electronic equipment. Fig. 2 shows an example of a TVS diode being connected and its functions.

In Fig. 2, the TVS diode is installed between the signal line connecting the external interface (I/O) and the IC and the ground (GND). The TVS diode switch is set to OFF during this normal operation. This isolates the signal line from the GND.

On the other hand, when the I/O is charged with electricity for some reason and there is a high voltage between the I/O and GND, ESD is liable to occur. If ESD is generated and intrudes here, the TVS diode will turn ON. The ESD will then flow to the GND via the TVS diode from the signal line.

The TVS diode protects the IC from the ESD by functioning like that.

Information equipment in recent years in particular has become smaller. At the same time, for instance, power supply input/output functions (USB Power Delivery (USB PD)) that support higher voltages and larger currents compatible with the USB4 high-speed data transmission I/O have started to spread. As a result, it is possible to say that measures against ESD in information equipment have become even more important (Photo 6).

Murata Manufacturing provides a range of various products including small TVS diodes as ESD protection devices that respond to needs such as for downsizing of electronic equipment and higher density device mounting. You can view details on TVS diodes from the link below.