CO2 sensor

CEATEC 2023

INDEX

Underwater CO2 sensor

Underwater CO2 sensor: Visualization of blue carbon absorption and sequestration volume

Blue carbon transactions are possible, but quantifying CO2 absorption remains an issue

Development of underwater CO2 sensor enabling easy measurement of CO2 absorption by seaweed beds

Lightweight heat transfer material employing biomass materials

Reconsideration of both filler and resin composing the heat transfer material

Murata’s DNA is alive in the new material

Conclusion

Leveraging accumulated technology and knowledge to contribute to environmental preservation

For products and services in every field and type of business, the superiority or inferiority of environmental performance supporting decarbonization or recycling has become an important consideration for consumers when making purchasing decisions. Nowadays, environmental performance is starting to have value beyond simply showing the commitment of a product’s maker and user to contributing to society.

Murata Manufacturing (Murata) is leveraging the technology and knowledge acquired from its existing businesses to create new technologies and new businesses that contribute to the realization of a sustainable society. At CEATEC 2023, held at Makuhari Messe from October 17 to 20, 2023, Murata unveiled some of the results of these efforts. Among the developers of new technologies on display, we interviewed Ms. Tempaku of the Corporate Technology Planning & New Business Development Group, Technology & Business Development Unit, who helped develop an “underwater CO2 sensor” that supports decarbonization and the restoration of the marine environment, and Mr. Onishi of the Material Technology Center, Environmental Technology Development Department, Technology & Business Development Unit, who helped develop a “lightweight heat transfer material employing biomass materials” that will contribute to the realization of sustainable electric and electronic devices.

--What are the functions provided by the underwater CO2 sensor, and how does this technology contribute to environmental preservation?

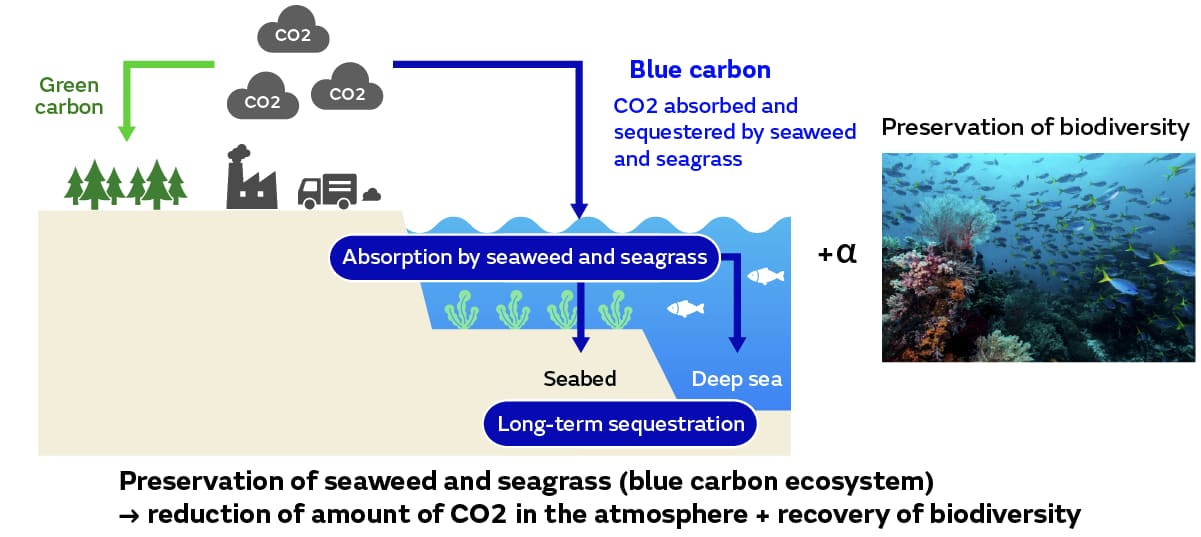

Tempaku: At Murata we are working to create businesses that support blue carbon, which is one of nature’s mechanisms for reducing the amount of CO2 in the atmosphere. The term “blue carbon” refers to CO2 that has been absorbed and sequestered through photosynthesis by seaweed and seagrass (Figure 1). The purpose of the underwater CO2 sensor is to measure the volume of blue carbon absorption and sequestration, which had hitherto been difficult to quantify. Alongside “green carbon,” which is CO2 absorbed and sequestered by trees and shrubs in wooded areas, blue carbon has gained attention as an important way to absorb and sequester CO2.

Absorption and sequestration of blue carbon occurs mainly in “seaweed beds,” which are “forests” in the ocean where seaweed and seagrass grow in abundance. By maintaining and expanding seaweed beds, we can increase the volume of blue carbon absorption and sequestration. In addition, small fish and other marine life dwell in seaweed beds, so increasing seaweed beds also helps to preserve biodiversity.

--You mentioned that quantifying blue carbon was difficult, but why was there a need for such quantification in the first place?

Tempaku: In recent years, a system called “J Blue Credit® certification” has been created to preserve and expand the blue carbon ecosystem by converting the quantity of CO2 absorbed by seaweed beds into economic value that can be used for transactions. Companies aiming to meet decarbonization targets can supplement their efforts by purchasing credits, and companies and organizations that cultivate and manage seaweed beds can sell credits and use the proceeds to accelerate their efforts to preserve and expand seaweed beds.

J Blue Credit® transactions can be completed via the Japan Blue Economy (JBE) Association. It is necessary to quantify the CO2 absorption of the seaweed beds in question when applying for credits, but this is not a simple process. Currently, the amount of CO2 absorbed by a seaweed bed is calculated based on the area of the seaweed bed, and the type of seaweed as determined by aerial photography using drones or visual confirmation by divers. This requires a high degree of specialization, and the survey cost is high. As a result, some of the funds received for credits must be used to cover survey costs and cannot be used to maintain the seaweed beds. This amounts to putting the cart before the horse.

In order to solve this problem, there is a need for methods to measure the amount of CO2 absorbed and sequestered as blue carbon simply, and at low cost.

--What is the operating principle used by the underwater CO2 sensor you developed to measure the amount of CO2 dissolved in water?

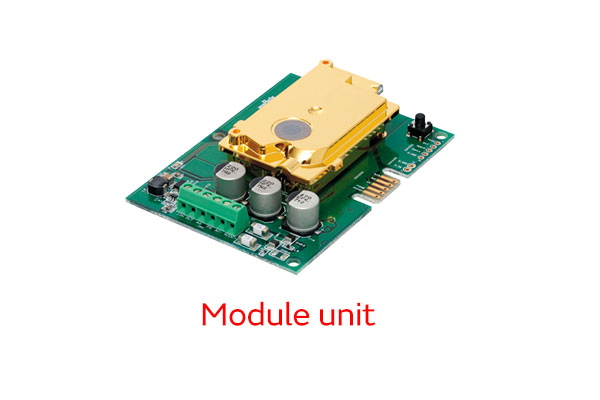

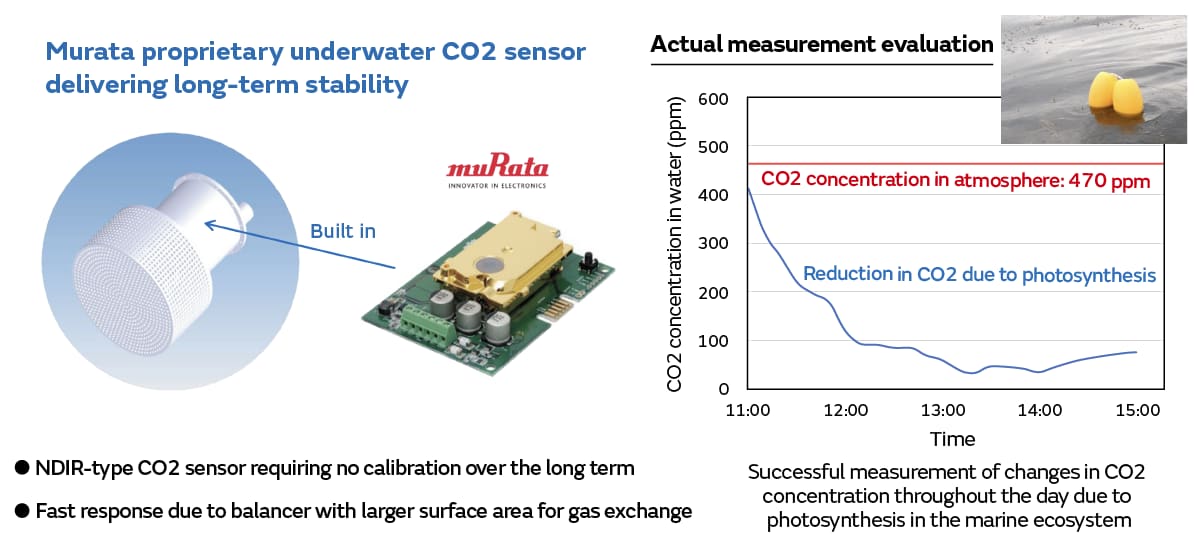

Tempaku: The development of the new sensor was based on an existing Murata product: a non-dispersive infrared CO2 sensor intended for climate control in office buildings and CO2 concentration management in agricultural greenhouses (Figure 2). This sensor requires no calibration and provides accurate and stable operation over long periods of time. But it is designed to detect CO2 in the atmosphere, not CO2 dissolved in water. Murata added a mechanism to extract CO2 from water in order to create an underwater CO2 sensor.

We have already brought the sensor to a seaweed bed and verified its functionality, confirming that we can detect things such as that the CO2 concentration changes with the amount of sunlight during the day due to photosynthesis in the marine ecosystem. The next step is probably to gather knowledge related to ways to increase the function of the seaweed beds and to expand their area effectively. With the sensor as a beginning, we are thinking of ways to contribute to biodiversity and visualization of conditions in the sea. We also think that the sensor can be used in environmental education aimed at children and students to help them clearly see the role played by seaweed beds.

--What functions does the lightweight heat transfer material employing biomass materials you developed provide, and how does this technology contribute to the sustainability of equipment in which it is used?

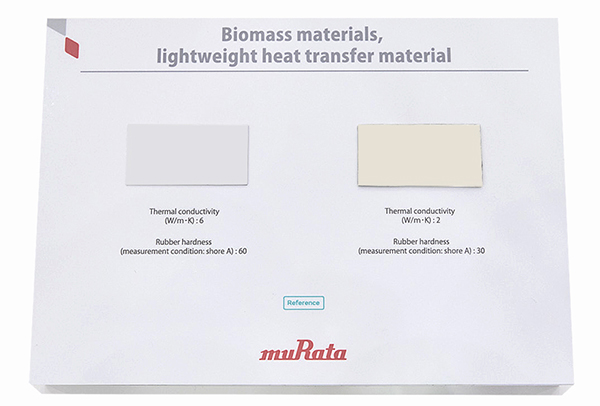

Onishi: As the name implies, the lightweight heat transfer material employing biomass materials we developed is a new type of lightweight heat transfer material that uses biomass materials, which help reduce environmental impact, as a portion of its raw materials. Placing this material between the heat-emitting parts of electric and electronic devices, such as semiconductors and batteries, and the exterior metal casing increases heat dissipation efficiency and reduces energy consumption.

Generally speaking, the heat-emitting components of electric and electronic devices are placed in contact with the metal casing of the device to provide a pathway for heat transfer. This allows the heat to escape to the outside. However, it can be difficult to maintain and guarantee stable contact points for effective heat escape, so the gap between the heat-emitting components and the casing is filled with a resin-based heat transfer material. The new heat transfer material we developed is intended as a replacement for the heat transfer materials in use up to now.

--What is the technology incorporated into the newly developed heat transfer material, and what effect does it realize?

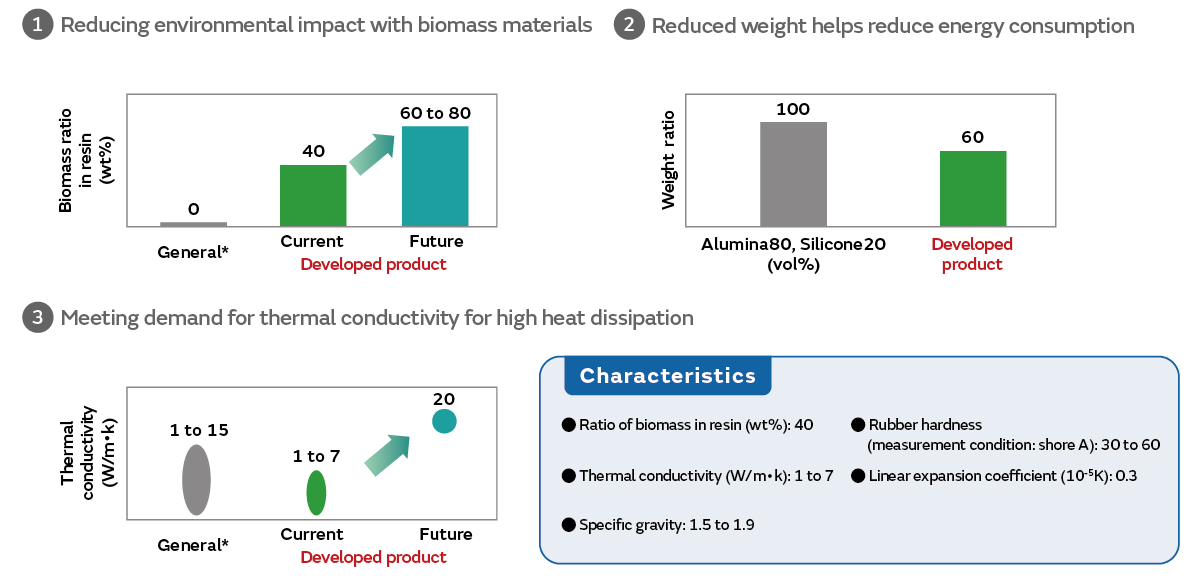

Onishi: A typical heat transfer material has a structure consisting of particles of ceramic or the like (filler) to transfer the heat held in place by hardened resin. Murata reevaluated both the filler and the resin to improve the environmental performance of the heat transfer material.

You might be surprised to learn how extensively heat transfer materials are employed for heat dissipation in high-performance electric and electronic devices. For example, in the automotive field, which is becoming “smarter” all the time, 5 to 6 kg of heat transfer material is typically used per vehicle, and this is likely to increase moving forward. Automakers, in order to reduce the consumption of electricity by electric vehicles and thereby reduce the amount of CO2 emitted generating the power consumed, are also working to reduce the weight of vehicles, starting from the component materials level.

Previous heat transfer materials typically used relatively heavy materials such as aluminum oxide or aluminum nitride as the filler. The new heat transfer material developed by Murata, on the other hand, benefits from the development of a new filler that is both lighter and delivers higher thermal conductivity. The new heat transfer material is 40% lighter than conventional materials (Figure 3).

Also, previous heat transfer materials employed silicone resin. When silicone is disposed of, it is either incinerated at high temperature or buried in a landfill, and disposing of 1 kg of silicone results in the production of about 2 kg of CO2. Murata uses biomass materials as the resin, effectively reducing CO2 emissions to zero. These biomass materials can be completely broken down at a comparatively low temperature of about 500°C, allowing them to be separated from the filler for easier recycling.

In addition, the newly developed heat transfer material has a linear expansion coefficient an order of magnitude less than that of conventional silicone. When a heat transfer material is used in an environment subject to extreme temperature variations, repeated expansion and contraction of the resin caused by the changes in temperature can cause the filler to separate from the resin. The new heat transfer material is less prone to this phenomenon, so it can help improve the reliability and extend the service life of electric and electronic devices.

--Heat transfer material is a different product category from the products Murata has handled in the past. How were you able to develop a unique new heat transfer material such as this?

Onishi: The newly developed heat transfer material draws on technology for creating homogeneous microscopic particles and evenly distributing them, which Murata perfected as part of the manufacturing process for multilayer ceramic capacitors (MLCCs). You might say that we were able to create this material because Murata already possessed the necessary technology.

In addition to automobiles, the newly developed heat transfer material can be used in a variety of application fields with electronic circuits that generate a lot of heat as their performance increases, such as cellular phone base stations. The number of electric and electronic devices requiring lightweight heat dissipation materials and improved environmental performance is sure to increase moving forward.

From the above it is clear that the exhibition at this year’s CEATEC of technologies such as the underwater CO2 sensor and lightweight heat transfer material employing biomass materials shows that when Murata leverages its accumulated technology and knowledge, it can create innovative new technologies that contribute to sustainability from unexpected starting points. Furthermore, many of the visitors to the Murata booth said things like, “To increase the value of our company’s products, we need to aggressively introduce technologies such as these that enhance environmental performance.” It would appear that there are myriad ways in which Murata can make contributions and proposals in response to the expectations of society and the times.

*The content of this article is current as of the publication date. Product specifications and external appearance subject to change without notice.