Gyro Sensors

Currently, there is a great deal of discussion being conducted in various countries regarding the “Fifth Industrial Revolution,” which follows on from the Fourth Industrial Revolution. The Fifth Industrial Revolution incorporates concepts such as “sustainability,” “human-centeredness,” and “concern for the environment” in addition to transformation of the industrial structure through the utilization of AI, IoT, big data, etc., which was debated in the Fourth Industrial Revolution.

In the following article, we introduce issues related to the Fourth Industrial Revolution and the initiatives of each country as well as the latest trends in the Fifth Industrial Revolution centered on the key technologies, etc., that are required within the latter.

In the Fourth Industrial Revolution, IoT brought convenience to people’s lives, and AI successfully automated complex tasks that could not be handled by conventional computers by learning from work data and making predictions and inferences. Moreover, marketing precision improved by predicting the operation and failure of equipment as well as the health and behavior of people through analysis of data collected from equipment connected to the Internet as big data.

In the manufacturing industry, information is collected from robots and automated processing machines through the network, for example. The use of computer control has enabled high-speed and accurate iterative operations, and the industry has successfully increased its ability to carry out mass production of a small variety of goods to a surprising level. Moreover, in our community life, unmanned stores, online medical care, electronic settlement, and the shift to online public services, etc., that utilize marketing data have brought convenience to people’s lives.

However, the Fourth Industrial Revolution does not incorporate sustainability that considers the global environment, a human-centered approach that takes human preferences into account, or circular economy initiatives that address resource problems. Moreover, because the focus is on vertical reforms such as one industrial field or one company unit, it is difficult to work across industries, companies, and departments, and the Fourth Industrial Revolution was limited in its ability to meet a wide range of social demands.

In order to resolve the issues of the Fourth Industrial Revolution in the Fifth Industrial Revolution, deeper and broader concepts are being advocated. Various countries have already announced one after another new concepts for realizing the Fifth Industrial Revolution following on from the Fourth Industrial Revolution. For example, the European Commission has announced “Industry 5.0,” which aims for an ideal industry based on the concepts of “sustainability,” “human-centeredness,” and “resilience,” while Germany has announced the “2030 Vision for Industrie 4.0” as the policy to follow Industry 4.0. Furthermore, in 2016, Japan announced “Society 5.0,” which aims to balance economic development with solutions to social issues. Here, we provide an overview of the Fifth Industrial Revolution and introduce the initiatives of Europe, Germany, Japan, and other countries.

The European Commission, which is the main institution of the European Union, announced in 2021 that Industry 5.0 would replace Industry 4.0. Industry 5.0 is a concept that complements and extends the perspectives of people, society, and the environment and is strongly influenced by the priority themes of the European growth strategy that was announced in 2019 and consists of “European Green Deal policies,” “A Europe fit for the digital age,” and “An economy that works for people.”

For example, in addition to realizing an industry for a society that is not susceptible to climate change by 2050, or in other words the realization of a carbon-neutral industry, Industry 5.0 aims to achieve global economic hegemony. As an example, it aims to create new markets for recycle-oriented products that are not susceptible to climate change such as the development of safe and sustainable chemical substances and steel manufacturing that realizes carbon neutrality, etc.

In Germany, the federal government has taken the initiative in promoting Industry 4.0 through an industry–government–academia collaboration system that includes private companies. Under the Fifth Industrial Revolution, Platform Industrie 4.0, which is the driving organization behind Industry 4.0 in Germany, announced in 2019 the “2030 Vision for Industrie 4.0” as the guidelines for the next 10 years as well as a report titled “Sustainable production: actively shaping the ecological transformation with Industrie 4.0” in November 2020.

The “2030 Vision for Industrie 4.0” proposes “Autonomy,” “Interoperability,” and “Sustainability” as important concepts. Regarding each concept, they specifically mention human-centered approaches such as improving labor conditions and education to support skill shifting, industrial and social transformation through collaboration across divisions and companies, and the realization of sustainable manufacturing such as resource efficiency improvement.

Perspectives and scenarios for giving shape to the sustainability that is a key concept of “2030 Vision for Industrie 4.0” are defined in “Sustainable production: actively shaping the ecological transformation with Industrie 4.0.” For example, it advocates the following three directions for sustainable manufacturing.

・Reduce consumption and increase the impact

・Shift from mass production to providing transparent services

・Links in a circular economic system

The scenarios are further detailed within these directions with the goal of accumulating specific scenario definitions and use cases and carrying out a rapid social implementation.

The Japanese government has already launched a plan to “balance economic development and the resolution of social issues through systems that integrate cyberspace (virtual space) and physical space (real space) at a high level” as Society 5.0, referring to a “human-centered society,” in 2016.

The Industry 5.0 report of the European Commission introduced Japan’s Society 5.0 as a leading concept that is highly regarded. In fact, Japan has strived for a long time to achieve coexistence with society and the environment and has respected spontaneous awareness and action through human-centered concepts. Moreover, the overwhelming speed of recovery during disasters was achieved through ties between industry, companies, and the government, which astonished the world.

However, while various countries around the world are currently promoting the Fifth Industrial Revolution, collaboration and leadership struggles aimed at global standardization are unfolding. It is expected that in order for Japan’s Society 5.0 to spread as a global standard in the era of the Fifth Industrial Revolution, proactive global collaboration and standardization activities are necessary.

Fifth Industrial Revolution movements are spreading not only in Europe, Germany, and Japan but also in the US and China.

The US is turning toward environmentally friendly policies, and in 2021, Germany’s Platform Industry 4.0 and the US’ CESMII (the Clean Energy Smart Manufacturing Innovation Institute) announced their collaboration in areas such as sustainable manufacturing to respond to the environment and climate change. In addition to expressing the stance that China will lead the world in the sustainability area in the “Made in China 2025” report that describes its vision for a national smart manufacturing policy, China has also announced green initiatives for the manufacturing industry.

Important concepts in the Fifth Industrial Revolution include “human-centeredness” and “sustainability.” Up until the Fourth Industrial Revolution, it was necessary to establish people and machines in separate workflows and spaces separated by safety barriers and other measures, as machines posed a danger to people. Moreover, the manufacturing of industrial products involved problems such as adverse effects on the human body and the environment. However, under the human-centered concept of the Fifth Industrial Revolution, people and machines will work in the same loop. Furthermore, technologies that are friendly to the human body and the environment are required to increase sustainability, and the integration of individual technologies is essential. Here, we use “collaborative robots” and “smart cell industries” as examples to explain new technologies in the Fifth Industrial Revolution.

Robots were the most frequently introduced type of machine in the Fourth Industrial Revolution, and among them, industrial robots that work in plant assembly, processing, conveyance, and distribution processes, etc., significantly contributed to increasing productivity. Industrial robots in the Fourth Industrial Revolution worked behind safety barriers, but in the Fifth Industrial Revolution, robots and humans performing tasks will work in the same space.

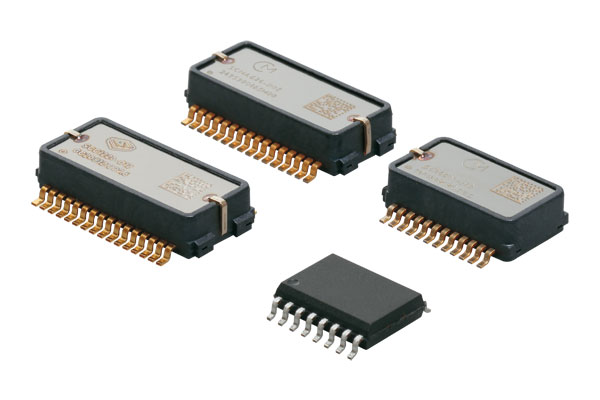

Industrial robots that work in the same space as humans in an environment with no barriers are called “Collaborative Robots” (Cobots). To ensure the safety of people, collaborative robots are equipped with ultrasonic sensors on robot arms that detect the proximity of people, accelerometers, which detect their operating speed, and gyro sensors that measure the inclination with a high degree of precision to perform accurate operations. Moreover, in cases where it is necessary to accurately assess the color or shape of the work, they are equipped with machine vision. In addition, the utilization of safety control software, etc., enables collaboration between people and robots. Furthermore, collaborative robots enable the simultaneous support of multiple items through integration and communication between machines, support for increases and decreases in production quantity according to demand fluctuations, and the construction of flexible production systems that can change production items.

Because collaborative robots that are human-friendly under the “human-centered” concept are safe and capable of operating close to humans, they can be utilized not only in plants but also service fields as well, and applications in areas such as medicine, education, restaurants, and retail are also increasing with the deepening of machine vision and AI.

A “smart cell” is a cell in which the material production capacity of a biological cell is highly designed through biotechnology and digital technologies such as information analysis so that it is controlled and maximized in the optimal way. Furthermore, “smart cell industries,” which operate smart cells as one material production plant, are a key technology of the Fifth Industrial Revolution.

Biotechnology has undergone a remarkable evolution and development through the integration with IT, AI, and other cutting-edge digital technologies in the Fourth Industrial Revolution. Smart cell industries have further promoted this integration. For example, research is being done on technologies that realize industrial product coloring that is gentle to the human body and the environment without fading by artificially reproducing the coloration techniques of living organisms that exist in nature without using harmful pigments. Heat- and impact-resistant resins derived from plants have already been developed and are being utilized in home appliance enclosures and exterior decorative parts for automobiles. Moreover, biofuels and gene therapies are also included in smart cell industries.

Smart cell industries such as these require digital technologies such as the analysis of massive volumes of information through AI, combination of modularized equipment for each manufacturing process, experimental humanoid robots, and the networking of all of these elements. It is not an overstatement to say that the further evolution of these digital technologies and their high-level integration with biotechnology hold the key to the realization of “sustainable” economic activities that are friendly to people and the environment in the Fifth Industrial Revolution.

In the Fifth Industrial Revolution, each country is launching various concepts that can be summarized as taking Fourth Industrial Revolution technologies based on “utilizing IoT or AI” to do something and adding the goal of realizing “human-centeredness, sustainability, and resilience including ecosystems” in the Fifth Industrial Revolution. That cannot be realized with standalone technologies but will involve the development of new infrastructure and the realization of an “ultra-smart society” through the high-level integration of IT and AI with robotics technology and biotechnology as well as cyberspace (virtual space) with physical space (real space). There is no doubt that as the Fifth Industrial Revolution era grows increasingly complex in this way, the companies that survive will be those that discuss these issues and work through the technological innovations.