Capacitor

Capacitor Guide

Final revision date: 13/09/2023

INDEX

In Part 1, we provided an overview of the different types of capacitors and of Murata’s ECAS series of polymer aluminum electrolytic capacitors. In Part 2, we will compare the characteristics of the different types of capacitors bringing in related data where relevant.

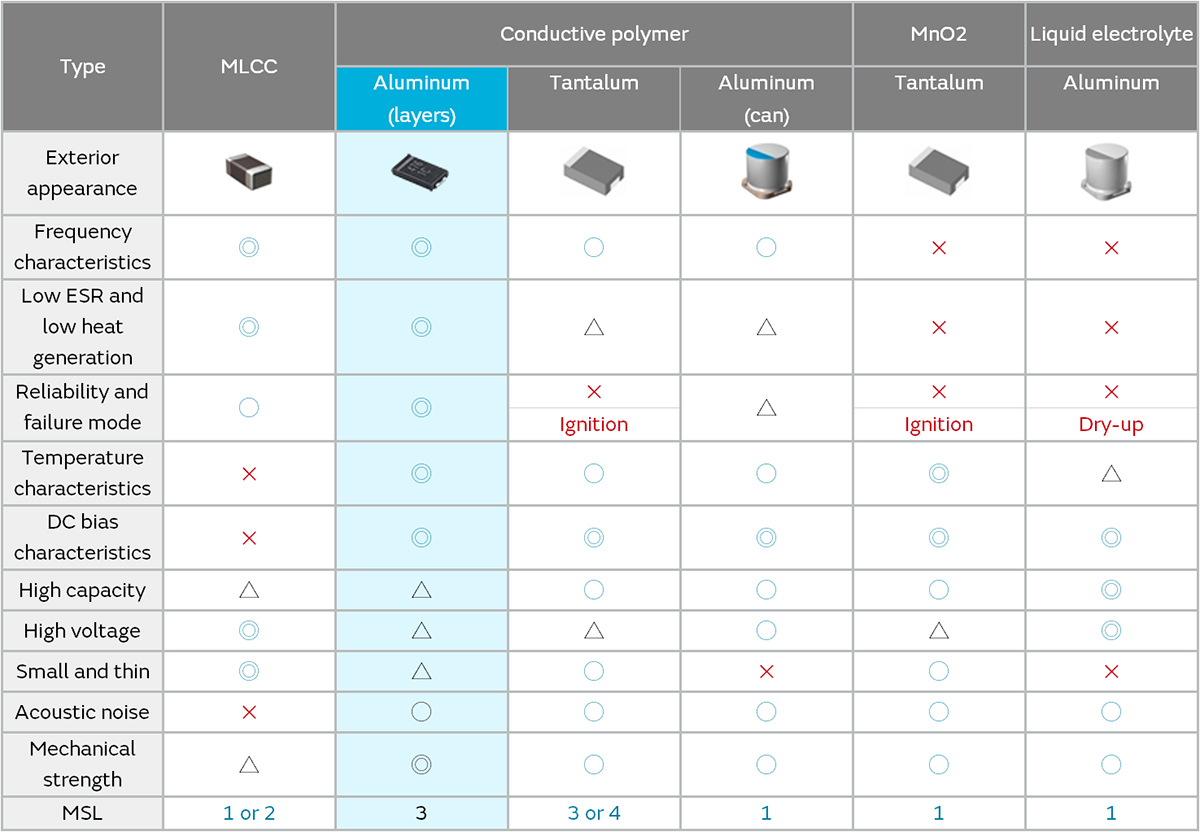

Fig. 1 is a comparative table of capacitor characteristics. Aluminum electrolytic capacitors (can type) using a conventional liquid electrolyte (electrolytic solution) and tantalum electrolytic capacitors using manganese dioxide (MnO2) are comparatively inexpensive, but they are inferior to polymer capacitors in their frequency characteristics, temperature characteristics, service life, and reliability.

The frequency characteristics, in particular, of Murata’s ECAS series of multilayer polymer aluminum electrolytic capacitors are superior to those of other polymer capacitors.

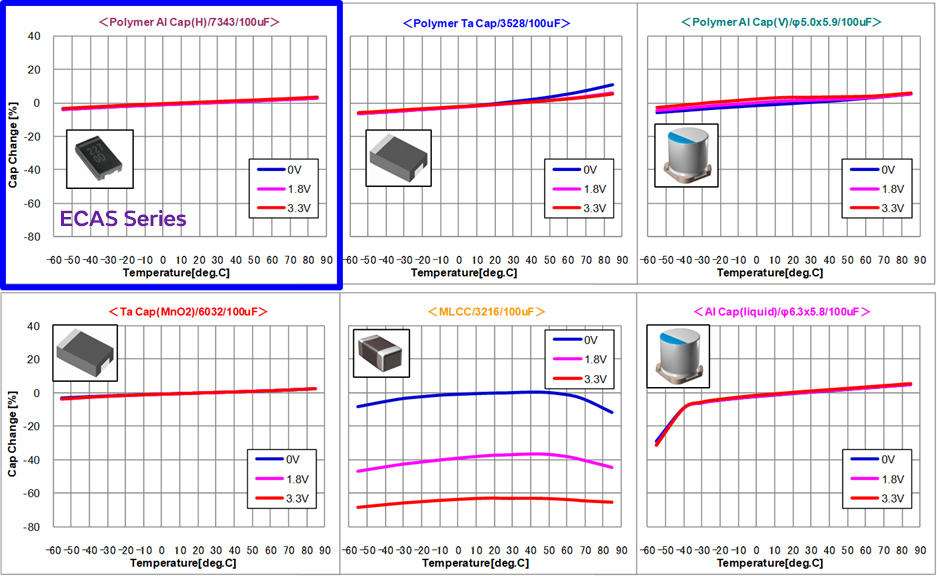

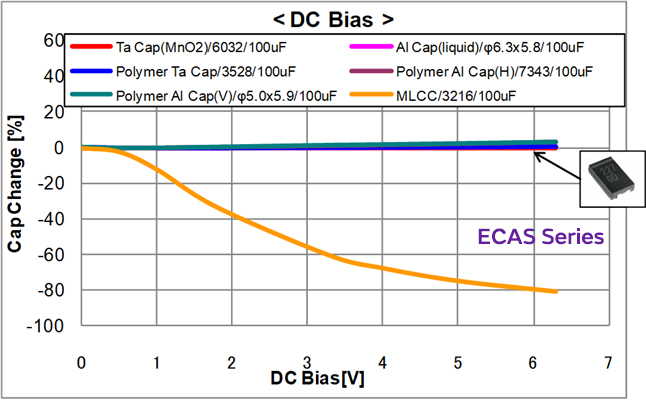

Now, let’s actually compare the characteristics of the six types of capacitors shown in Fig. 1. The evaluation items are all for ratings of 6.3 V/100 µF. (The data listed is intended as an example and to be used only for reference.)

Fig. 2 shows comparative data for impedance and ESR frequency characteristics. Generally speaking, the lower the ESR or impedance of a capacitor, the better its smoothing characteristics or transient response characteristics when used in an actual circuit.

Multilayer ceramic capacitors (MLCCs) have the lowest ESR and impedance, followed by multilayer polymer aluminum electrolytic capacitors (ECAS series). These are followed by other types of conductive polymer capacitors, tantalum electrolytic (MnO2 type) capacitors and aluminum electrolytic (liquid electrolyte type) capacitors. MLCCs consist of multiple staked layers, each composed of a barium titanate (BaTiO3) dielectric and an electrode. In the equivalent circuit, the individual layers are connected in parallel, resulting in a low ESR. The capacitors in the ECAS series also consist of multiple layers of aluminum elements, though fewer layers than in an MLCC, enabling them to achieve a low ESR as well. Other types of capacitors basically consist of a single capacitor element, so their ESR tends to be comparatively high.

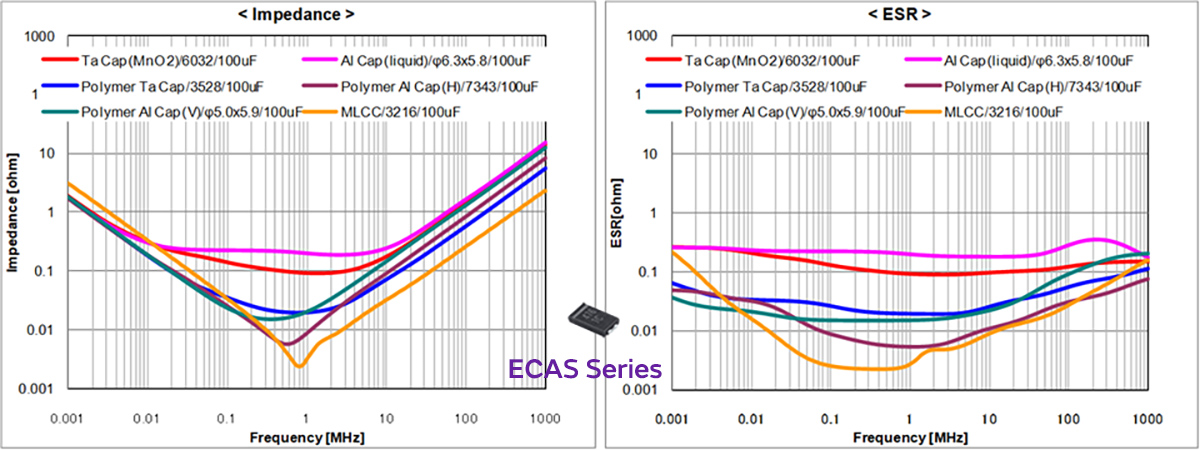

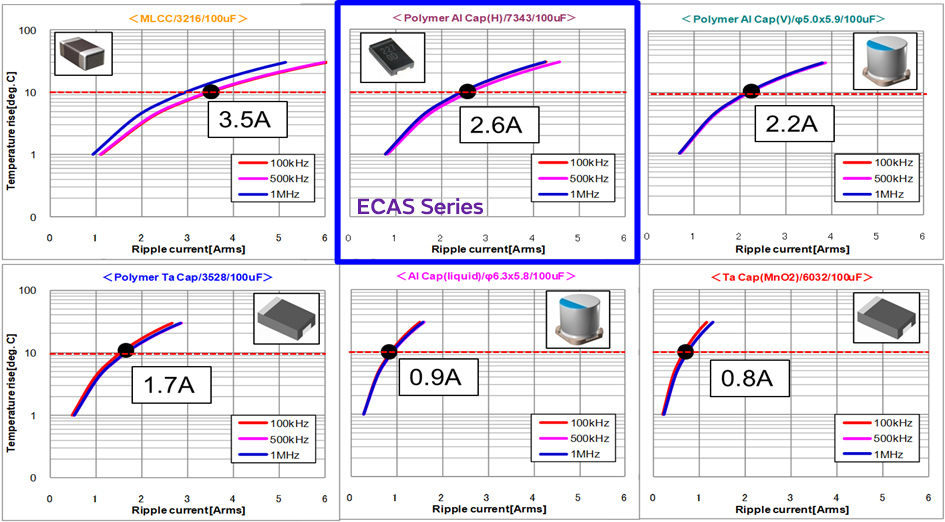

Next, Fig. 3 shows the heat generation characteristics of capacitors due to ripple current. The more gradually and stably a capacitor rises in temperature, the better its characteristics as a capacitor. The amount of heat generation is related to factors such as ESR and the capacitor’s physical volume. Excessive heat generation can adversely affect reliability and service life.

For example, let’s compare the amount of current that can flow when the temperature rise is limited to 10°C. In an MLCC, where ESR is lowest, the largest ripple current can flow. This is followed by the multilayer polymer aluminum electrolytic capacitor (ECAS series) and then by other types of conductive polymer capacitors, aluminum electrolytic capacitors (liquid electrolyte type) and tantalum electrolytic capacitors (MnO2 type).

Generally speaking, MLCCs have extremely low heat generation, so this characteristic is rarely guaranteed in the specs. In electrolytic capacitors, including conductive polymer capacitors, the effects of heat generation cannot be ignored, so this characteristic is generally stipulated for each product model.

Refer to the following webpage for information on ripple current in MLCCs:

Next, Fig. 4 shows capacitance temperature characteristics. In all-solid conductive polymer capacitors and MnO2-type tantalum electrolytic capacitors, there is almost no change in the capacitance when the temperature changes. A typical aluminum electrolytic capacitor, however, has difficulty producing the rated capacitance at low temperatures because it uses a liquid electrolyte (electrolytic solution). The temperature characteristics of MLCCs differ according to the dielectric type, and the capacitance does exhibit temperature dependency. As the capacitors in the ECAS series have stable temperature characteristics, they can be used without concern for the usage environment. (In actual use, the maximum usage temperature is such that the capacitor’s surface temperature, including any self-generated heat, should be kept below 105°C.)

Refer to the following webpage for information on MLCC temperature characteristics:

Finally, Fig. 5 shows a comparison of DC bias characteristics. In electrolytic capacitors, including conductive polymer capacitors, the dielectric constant does not vary when the application voltage changes, so the capacitance does not change when voltage is applied. The fact that the capacitance does not vary when the rated voltage is applied is a strong point of electrolytic capacitors.

Though it does depend on the dielectric type, MLCCs are susceptible to structural distortion when DC voltage is applied. This is especially true when the dielectric used has a high dielectric constant. Thus, there is a tendency for the capacitance to be highly dependent on the DC bias. However, MLCCs that exhibit less capacitance variation have recently been developed.

Refer to the following webpage for details of the mechanism whereby the capacitance of an MLCC changes when DC bias is applied:

The comparison of characteristics outlined above is only partial. Each type of capacitor is well suited to some fields and poorly suited to others. When actually designing circuits, it is necessary to consider a number of factors in addition to the characteristics described above, such as cost and size, in order to select the best capacitor for the job.

Typical aluminum electrolytic capacitors can be said to be suitable in cases where there are no space constraints and large capacitance is the only relevant characteristic, whereas conductive polymer capacitors are a good choice when both capacitance and ESR are important. If space is limited, all-purpose MLCCs are best. MLCCs are also suitable for applications where the ability to deal with very high voltages is needed because of their high withstand voltage performance and ability to withstand reverse voltage.

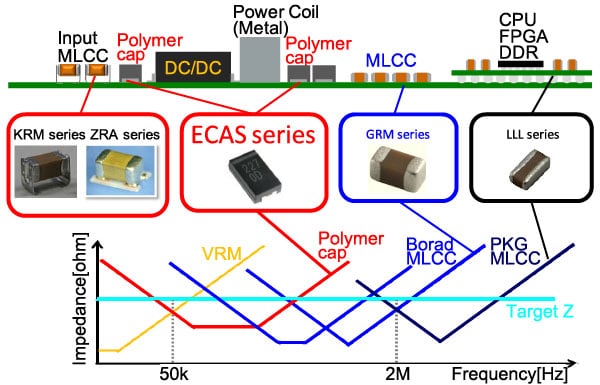

As ECAS series capacitors combine low ESR and comparatively high, stable capacitance, they are particularly well suited for current smoothing and improving transient response characteristics in power lines subject to sudden load fluctuations, such as CPU or FPGA power lines. And as they have a lower profile than can-type aluminum electrolytic capacitors, ECAS series capacitors are suitable for use in electronic devices where thinness is required. Their stable capacitance temperature characteristics also make them suitable for electronic devices intended for use outdoors.

Fig. 6 is a summary view that shows a motherboard as viewed from the side. Passive components of the sort shown here are typically arranged around the active components such as the CPU and DC-DC converter. Basically, it is necessary that the target impedance is met in order to ensure that electronic devices operate properly. A variety of capacitors of different types are arranged in combination to achieve this.

In addition to a wide variety of MLCC products, Murata Manufacturing Co., Ltd. also offers a lineup of polymer aluminum electrolytic capacitors that provide coverage for lower frequency bands. The ability to provide one-stop shopping for the full range of input and output capacitors needed for power lines is another of Murata’s strengths. When designing future electronic devices, be sure to consider Murata’s polymer aluminum electrolytic capacitor (ECAS series).

Refer to the following webpage for details of the ECAS series lineup:

Produced by: Chemical Device Product Department, Murata Manufacturing Co., Ltd.