Noise Suppression Products / EMI Suppression Filters / ESD Protection Devices

Noise Suppression Filter Guide

In Part 1, we discussed noise problems associated with wireless power transfer and their mechanisms. In Part 2, we will talk about specific noise suppression techniques.

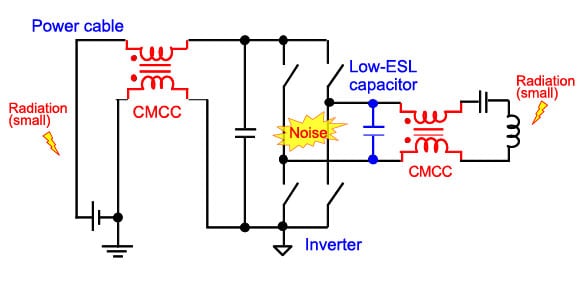

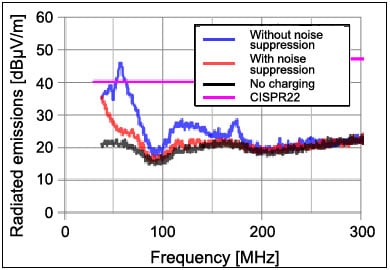

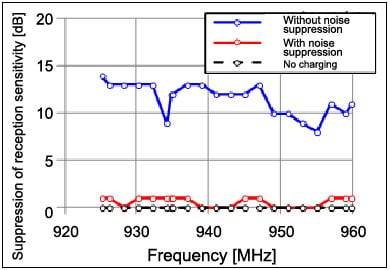

A. The basis of noise suppression is to suppress the noise generated by the noise source before it can reach an antenna, from which it is readily radiated. Wireless chargers are no exception to this rule. Inserting a common mode choke coil (CMCC) at the base of the power cable was an effective way of reducing radiated emissions, and we found that inserting a low-ESL capacitor and common mode choke coil before the transmitter coil effectively improved the reception sensitivity.

Figures 5 and 6 show the specific improvements achieved. Inserting a common mode choke coil at the base of the power cable reduced radiated emissions by as much as 20 dB or so, bringing the device into compliance with CISPR 22. Inserting a low-ESL capacitor and common mode choke coil before the transmitter coil boosted reception sensitivity by up to approx. 13 dB, which was about the same level as when no charging was taking place.

A. For the common mode choke coil at the base of the power cable we use the DLW5BTM102SQ2, DLW5BTM102TQ2, DLW5BTM142SQ2, and DLW5BTM142TQ2. These parts provide excellent performance in eliminating noise at frequencies of several tens of megahertz, which is the problem area for radiated emissions, and their rated current of 1.5 A to 2 A is sufficiently high. These products are ideal for noise suppression in applications of this sort. For the common mode choke coil before the transmitter coil we use the DLW5BTM101SQ2, DLW5BTM101TQ2, DLW5BTM251SQ2, and DLW5BTM251TQ2. These parts deliver excellent performance in eliminating noise over the wide frequency band from 200 MHz to 1,000 MHz where reception sensitivity is a problem, and their rated current of 5 A to 6 A is sufficiently high. They also have almost zero normal mode impedance at 100 kHz, so they do not adversely affect the behavior of wireless power transfer operation. For the low-ESL capacitor before the transmitter coil we use the LLL185R71H222. It has excellent noise elimination performance over the same wide frequency band from 200 MHz to 1,000 MHz as the common mode choke coil, and its rated voltage of 50 V is sufficiently high. It also has extremely low capacitance of around 2,200 pF, so it does not adversely affect the behavior of wireless power transfer operation.

Click here (Noise Suppression Products / EMI Suppression Filters),(Ceramic Capacitor) for more detailed information.

A. Most smartphones currently on the market use chargers rated at 5 W or less, but moving forward I expect the wattages to increase.

Tablets with 15 W chargers are expected to come on the market in 2015. Use of such chargers will then spread to PCs and electric home appliances, and eventually we may see a day when power cords have disappeared from the home completely.

The development of wireless power transfer is also advancing in the automotive field. Several years from now we can expect to see practical applications.

And there are even plans for the more distant future that envision embedding wireless chargers in every road and guardrail so that drivers will never have to worry about running out of gas or battery power. Wireless power transfer is also a focus of attention in the medical field, where it is expected to be used in devices implanted in the body such as pacemakers. Users of today’s pacemakers have to undergo periodic surgical procedures to replace the batteries, but a pacemaker equipped with wireless power transfer could be charged without the need for surgery.

In this way, we can expect wireless power transfer to find future applications in a wide variety of fields. This technology even has the potential to change the way we live our lives.

Department Responsible: Application Development Sec. Product Development Dept. EMI Filter Division, Murata Manufacturing Co., Ltd.

The information presented in this article was current as of the date of publication. Please note that it may differ from the latest information.