Capacitor

PRODUCT FOCUS

AEI by Dempa Publications, Inc., December 2017

As demand is rising for high-speed and high-capacity data communication, and the functionality of assembled products is expanding, an increasing number of multilayer ceramic capacitor chips (MLCC) are used in mobile communication devices. In particular, each smartphone uses a huge number of MLCCs; high-end models have 600 to 1000 MLCCs, and even low- and middle-end models have 300 to 600 MLCCs. As demand will continue to rise for higher functionality, lower-power consumption assembled products, their components will increasingly need to be more compact and to have higher performance.

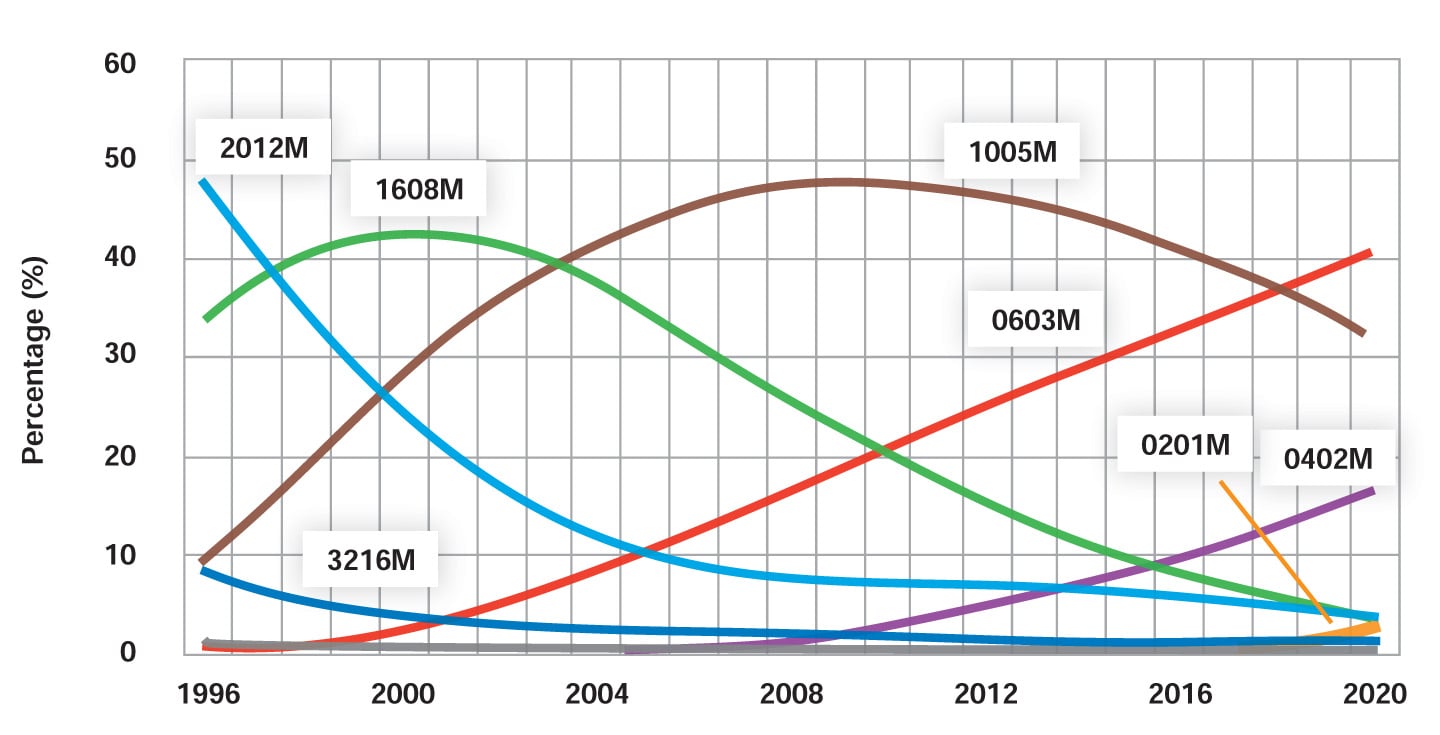

As shown in Figure 1, a downward shift in the size of MLCCs tends to take place on an approximately 10-year cycle, and in the consumer market, the 1005M*1size is being replaced by the 0603M size as a major size. Miniaturization for E1 step capacitance is a major factor behind this trend. Around 2010, by developing 0402M/0.1μF, 0603M/1μF, and 1005M/10μF products, Murata Manufacturing Co., Ltd. was able to significantly contribute to miniaturization and high-density mounting of components in feature phones and smartphones. There are high expectations for further contribution of MLCCs to miniaturization and high-density mounting.

This article describes Murata’s efforts on MLCCs contributing to the miniaturization, improved mounting density, and increased performance of assembled products and module components.

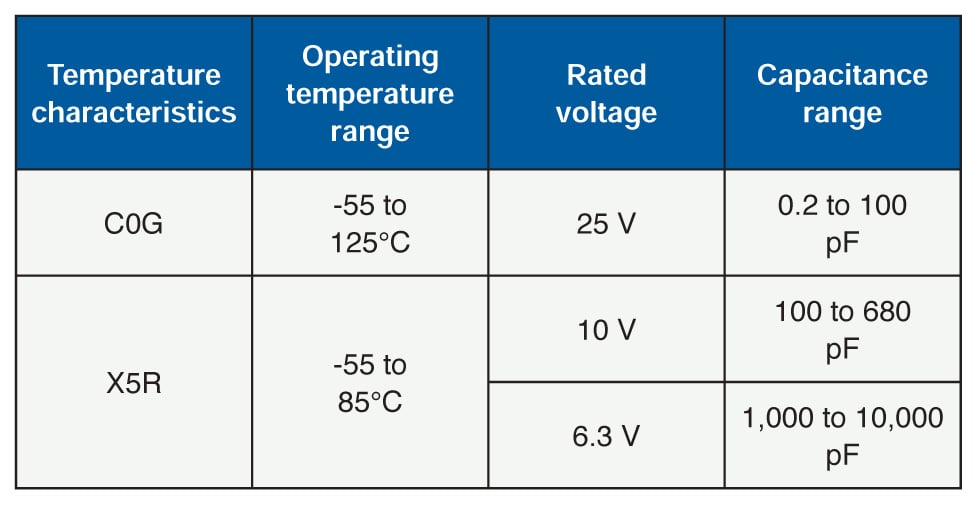

Murata has mass produced the smallest 0201M-size (0.25 × 0.125mm) MLCC since 2014. A photo of the product and the product lineup are shown in Photo 1 and Table 1, respectively. As mentioned in section 1, as the functionality of mobile communication devices, like smartphones is expanding, the usage of MLCCs is rising and their miniaturization is progressing; moreover, 0201M-size components are increasingly needed for wearable devices and small modules.

The 0201M size (0.25 × 0.125mm) MLCC requires only half the mounting space of the 0402M size (0.4 × 0.2mm), the previous smallest size, thereby contributing to smaller mounting space. Since, however, it is an unprecedented small size, the establishment of mounting techniques was needed. Murata has made efforts to not only optimally design products and packaging material, but also establish mounting techniques in cooperation with manufacturers of mounting machines, soldering materials, circuit boards, among others. As a result, it is becoming possible to mount the products on wearable devices and small module devices. The company plans to develop 0201M-size/high-Q series products suitable for matching use in high-frequency circuits, and 0201M-size/0.1μF products, expecting that full-scale spread of the 0201M size will start.

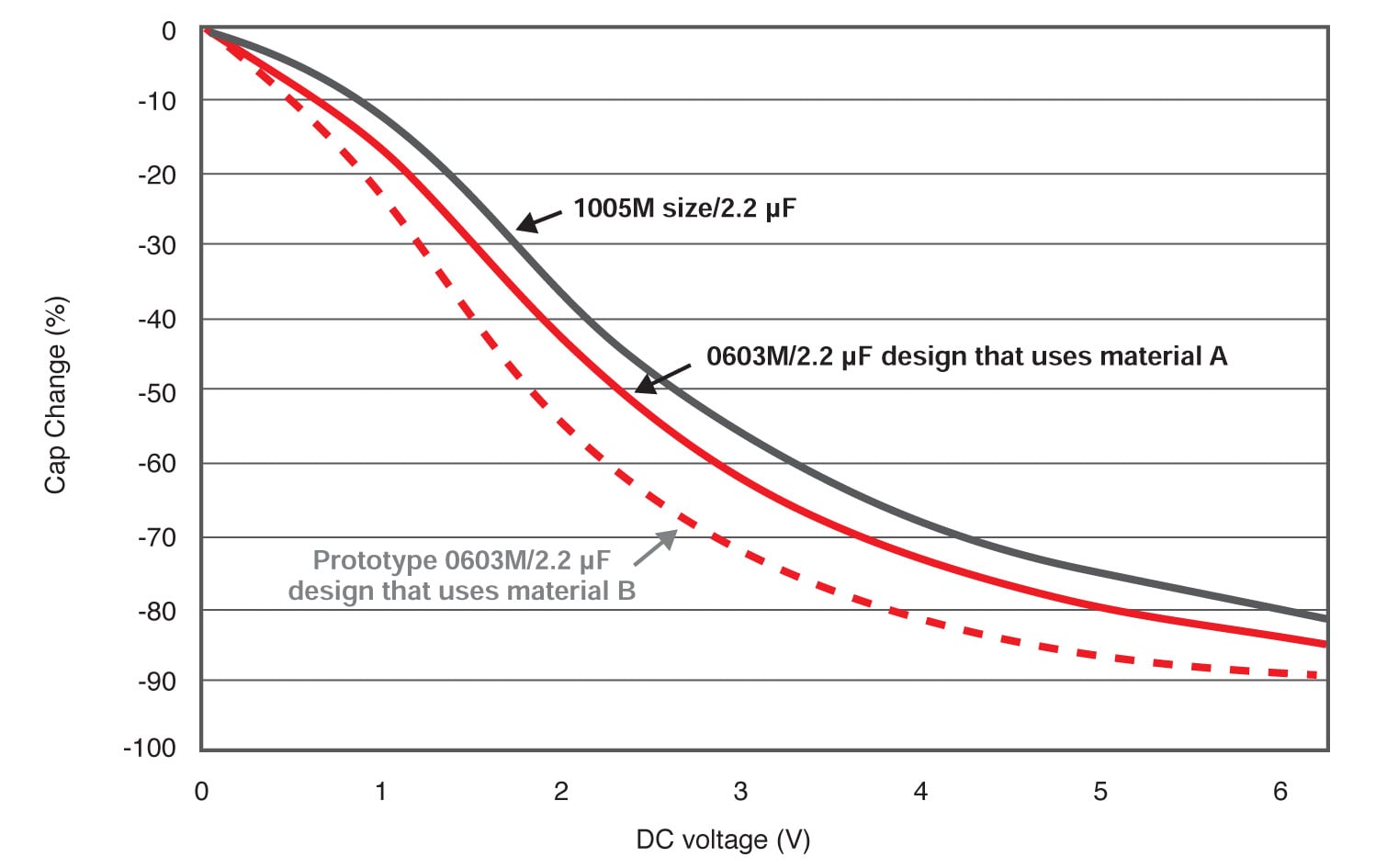

MLCCs have voltage characteristics associated with the characteristics of their respective ceramic materials used. Thus, their effective capacitance varies depending on the DC or AC voltage. Temperature compensation MLCCs (C0G characteristics and others) use paraelectric ceramic with a low dielectric constant, and so their capacitance rarely changes depending on the voltage characteristics. However, as high-dielectric constant MLCCs (X5R or X7R characteristics and others) use ceramic material with a high dielectric constant typified by barium titanate, their capacitance significantly changes depending on the voltage characteristics.

When an MLCC is miniaturized, the capacitance can be secured by increasing the dielectric constant of the ceramic material or by thinning the layers of the device. However, if the dielectric constant is increased, the effects of the voltage characteristics will become more significant, and the capacitance may become small under the actual operating voltage, as compared with non-miniaturized products of the same kind.

In order to design small products with effective capacitance in mind, the company has focused its efforts on developing thin-layer technology for ceramic materials and internal electrode materials, and high-reliability technology for thin-layer design so that it can provide thin-layer design by using materials with a reduced dielectric constant. As a result, it has successfully designed products that are superior in effective capacitance to those that use ceramic material with a high dielectric constant, although they are inferior in effective capacitance to non-miniaturized products of the same kind. As an example, Figure 2 shows DC voltage characteristics of the capacitance of a 0603M-sized, smaller version of a 1005M-size/2.2μF product. The figure shows that although the effective capacitance of the prototype design that uses ceramic material B, which has a high dielectric constant, greatly drops as compared with the non-miniaturized version, the design that uses ceramic material A, whose dielectric constant is reduced, maintains changes in the capacitance in the same manner as the non-miniaturized version.

Characteristic changes under the actual operating conditions like those in Figure 2 may cause gaps between the results of circuit design simulation and actual operation. In order to carry out circuit simulations that consider characteristic changes, the company has developed dynamic models*2 of MLCCs that reflect specified temperatures and DC bias voltage characteristics. These models can be downloaded from its website. Murata’s design support software SimSurfing,*3 which is also available on the website, enables users to graphically display various characteristics calculated by using the dynamic models. Also, it offers Sim Search, which allows reverse lookup of components from the effective capacitance required under desired DC voltage conditions and temperature conditions. These are utilized to select components or carry out a high-accuracy circuit simulation, and are receiving high evaluation.

This article describes Murata’s efforts on its MLCCs that contribute to miniaturization of assembled products and module components and to the improvement of their mounting density and functionality. Murata believes that miniaturization of components will improve productivity, leading to stable supply of MLCCs, which are becoming widely used. Probably, market demand will continue to rise more and more for miniaturization of components and their high-density mounting. The company will continue to not only offer miniaturization of components and their high-density mounting, but also design products with the characteristics under the actual operating conditions in mind, making proposals for more easy-to-use solutions.

Notes:

*1 Size in which the L×W dimensions are 1.0 × 0.5mm. The dimension symbol identifi er M denotes the metric unit.

*2 Dynamic model: Component model for simulation that can dynamically reflect the cause of gaps in characteristics

*3 Design support software SimSurfing website:

https://ds.murata.com/simsurfing/index.html?lcid=en-us

About This Article:

The author is Hiroshi Tamura,Product Engineering Section 1, Product Engineering Dept., Capacitor Division 1, Components Business Unit, Murata Manufacturing Co., Ltd.