RFID Products

PRODUCT FOCUS

AEI by Dempa Publications, Inc., July 2017

UNLIKE BARCODES, RFID CAN SIMULTANEOUSLY READ MULTIPLE TAGS, AND ALLOWS COMMUNICATION OF SEVERAL PRODUCT INFORMATION, RESULTING TO BETTER TRACEABILITY OF PRODUCTS.

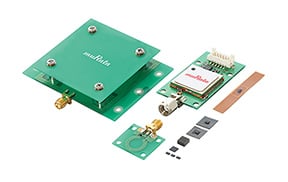

Murata Manufacturing Co., Ltd. offers the ultrasmall radio-frequency identification (RFID) tag LXMS21NCNH-147 (MAGICSTRAP®) (Photo 1) and the reader/writer LXRFZZUAA Series (Photo 2). LXMS21NCNH-147 is a 2012-size (2.0 × 1.25mm) tag that serves as an alternative to barcode for inventory management and history tracking for small devices, and can be read even after product assembly. Meanwhile, LXRFZZUAA Series is a reader/writer series suitable for reading the RFID tag.

RFID is a wireless automatic identification technology, or a system that identifies and manages various items using IC tags. It can read/write data in a contactless manner using radio waves; therefore, unlike barcode systems, which read tags one by one, it can read multiple tags at once, and is capable of communication even at a distance of several meters as far as radio waves can reach.

RFID, an automatic identification technology studied and spread from the late 1990s to the early 2000s, is steadily penetrating markets, particularly logistics and apparel industries. As it facilitates inventory management and history tracking through the addition of unique IDs, there is an increase in requirements for its use as an alternative to barcodes. However, there are many issues related to ensuring traceability for small devices typified by activetracker, eyewears, wearable devices, wireless earphones, hearing aids, and the like, because of the sizes of these products.

The RFID tag that Murata released in 2008 (MAGICSTRAP®) is mounted on a printed circuit board (PCB) to use the ground pattern as the antenna, thereby allowing the PCB itself to be used as an RFID tag. However, it is becoming difficult to create an antenna in small devices because of their very small PCB area. Also, it is difficult to secure an area for a 2D barcode in casings, and laser marking requires disassembly of products after their assembly when barcodes are read.

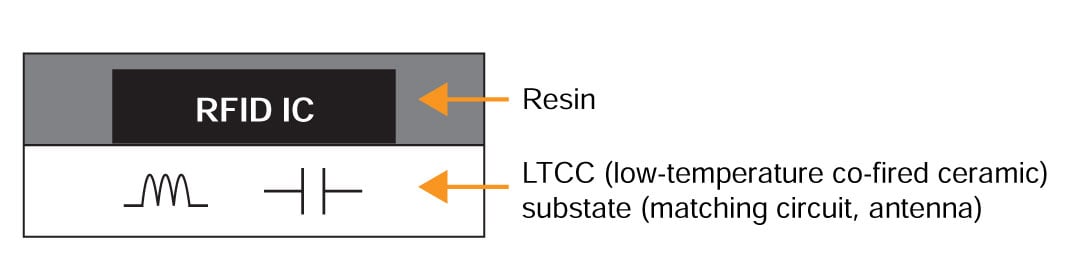

Therefore, Murata developed LXMS21NCNH-147 (MAGICSTRAP®) and an RFID reader/writer (Figure 1). LXMS21NCNH-147 is an ultrasmall RFID tag with a built-in antenna, which can be embedded in a limited space in products.

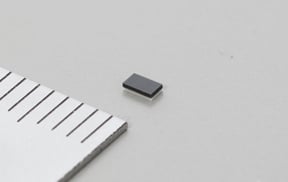

Ultrasmall RFID tag (MAGICSTRAP®) LXMS21NCNH-147 is among the industry’s smallest with built-in antenna (Figure 2) at 2.0 × 1.25 × 0.55mm. It features high level of robustness. It is compliant with ISO18000-63 and EPCglobal Gen 2 (v1.2.0), which are ultra high frequency (UHF) band RFID standards, and is operable at a wide range of UHF RFID frequencies in various countries from 865 to 928MHz. It has 512-bit internal user writable memory area.

Meanwhile UHF RFID reader/writer LXRFZZUAAA Series is available in product versions that are compatible for bands in Japan, United States and countries in Europe. They have received certifications from respective regulators, for example FCC and IC for North America, ETRI for Europe, and other certifications for technical standards conformity in Japan. It is compatible with the universal asynchronous receiver/transmitter (UART) interface. This series is provided with a starter kit equipped with a Universal Serial Bus (USB) interface and an antenna.

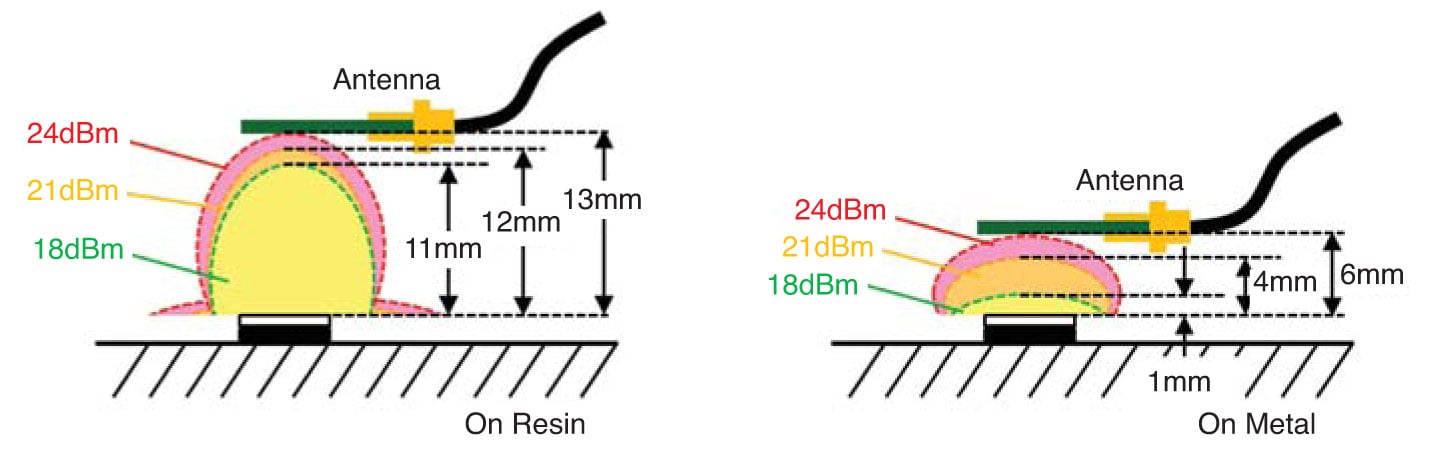

The communication distance at which LXMS21NCNH-147 is read by the LXRFZZUAAA Series reader/writer is approximately 13mm (at an output of 24dBm) in free space (Figure 3). When this RFID chip is embedded within the casing of a small device, it is possible to read the information of the RFID tag from outside the casing, although there is a slight decrease in the communication distance.

This makes it possible to not only identify individual products in manufacturing processes, but also read the serial numbers of products even in the aftermarket simply by holding up a reader/writer over the products without disassembling them.

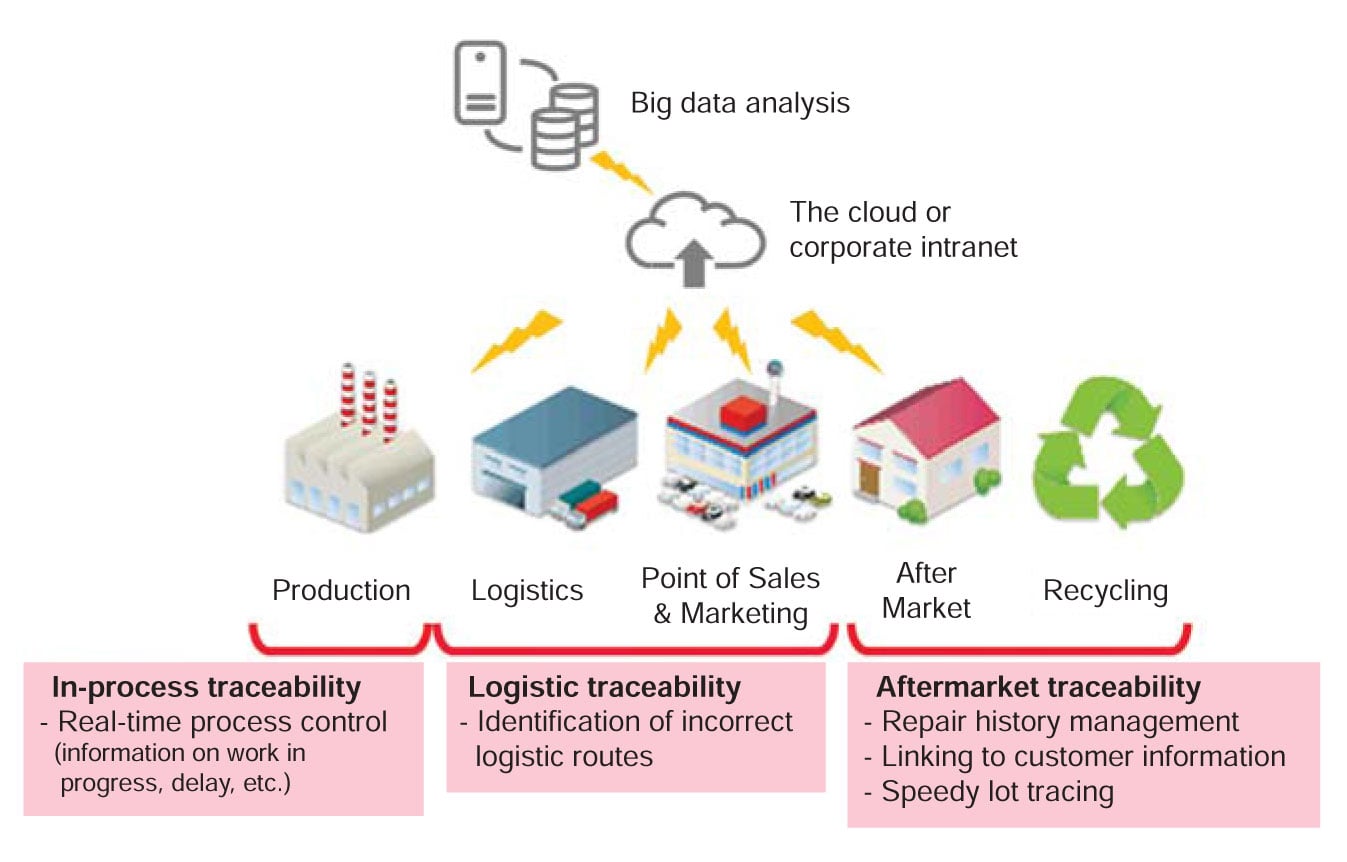

Therefore, referring to information on manufacturing lots can be done immediately or getting the repair history at a service center, resulting to expected improvements in customer services (Figure 4).

If there is a metal between the tag and the reader/writer, radio waves are blocked and the RFID cannot perform communication; therefore, at present, it is necessary to place RFID tags in a location where non-metal materials such as plastic are used. Murata Manufacturing will make efforts to offer solutions that allow tags to be read even when they are completely covered by metal, like analog watches, high-end smartwatches.

About This Article:

The author is Teppei Miura from RFID Business Development, Technology Integrated Products Department, New Products & Business Division, Murata Manufacturing Co., Ltd.