RFID Products

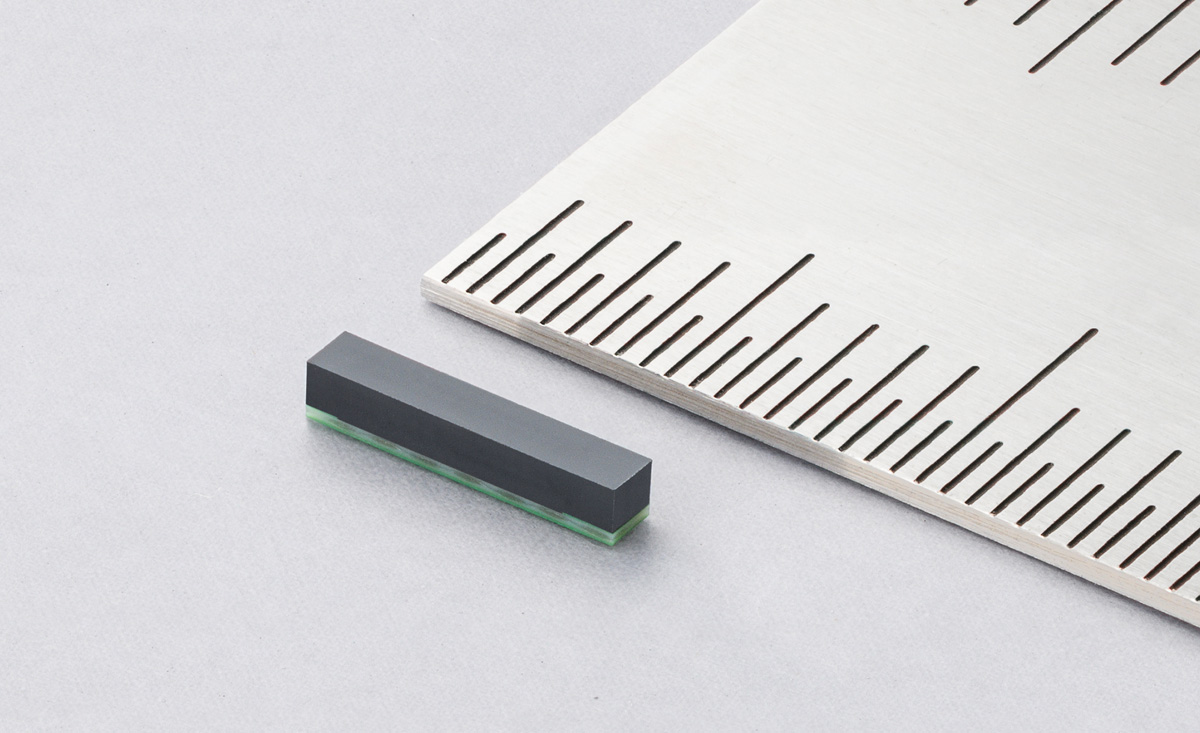

Murata Manufacturing Co., Ltd. ("Murata") has developed a tough and small radio frequency identification (RFID) module that can be embedded into tires in collaboration with world-leading French tire manufacturer Michelin. This module is an extremely small part with a size of 6 mm × 1 mm × 1 mm. Nevertheless, it is a product that will bring about innovation in the tire business.

Each company in the automobile industry is working on what is being called a once-in-the-century revolution due to the CASE trend. CASE is a trend evolving the vehicle and automobile business along four axes of evolution: Connected (C), Autonomous (A), Shared & Services (S), and Electric (E).

Within CASE, we tend to be captivated only by changes, automation, and electrification of automobiles themselves with their presence that is familiar to us. However, conversely, the business side is changing greatly, with a focus on Connected and Shared & Services. The form in which automobiles are used will transition from "possession" to "use." Furthermore, the profit model of the automobile business will transition from the "simple sale of goods" to "services." This will open up a new era in the utilization of mobility.

Similar trends are also descending on manufacturers that make tires and other automobile parts in addition to automobile makers. Michelin is one of the tire manufacturers that are proactively striving to provide new value by turning the tire business into a service-based business. The company has clarified its plans to embed all tires it manufactures with RFID chips that grasp in real time data on the use and management of tires. It is also building an IoT system that will grasp real-time data on the use and management of tires mounted on cars by utilizing RFID. It is trying to make use of this in the provision of predictive maintenance services, the operation management of vehicles, improvement of the waste tire recycling rate, inventory management in dealers, and other areas.

RFID is a technology that automatically identifies and manages things through wireless communications by using IC tags and other devices. It has the advantage in that it targets multiple tags, making it possible to read a lot more data easily at once compared with barcodes and other recognition technologies. It also enables the rewriting of data. RFID is therefore utilized in various settings (e.g., manufacturing, logistics, and sales) as a technique to collectively identify and manage the states and movements of many things.

The movement to embed RFID into tires and then to utilize that to optimize various areas of management and to create a new business model is also spreading among many tire manufacturers. Michelin's concept is to embed RFID tags into tires to connect them to the IoT. It envisions that those tags will be used to manage the usage history over the entire lifecycle of tires – from when they are made to when they are mounted to cars and their use after being launched onto the market and even up to their disposal. For example, tires utilized after their worn rubber has been replaced are used in trucks, buses, and other commercial vehicles. They are called retread tires. Embedding RFID into tires makes it possible to easily, accurately, and efficiently manage the mounting position, time, and date, number of repairs, and other information of tires for the vehicle just by using a portable scanner to scan the ID recorded in the RFID tag. Moreover, Michelin also plans to use the same RFID tags to ensure traceability and to optimize operations.

The technical level required to connect tires to the IoT is extremely high compared to connecting office equipment and home appliances to the IoT. That is because the usage environment of tires is harsh. Furthermore, it is also because high reliability and safety is sought in tires.

Many existing RFID tags were used by affixing them to cardboard boxes and other items that contain products. They are then discarded after the product reaches the consumer. Therefore, there was no need for the RFID tags themselves to be that durable. By contrast, the usage setting envisioned by Michelin is that the tags will be embedded into tires used in various weather conditions, road surfaces, and driving situations. Moreover, it is necessary that they function over a long period of time until the tires are discarded.

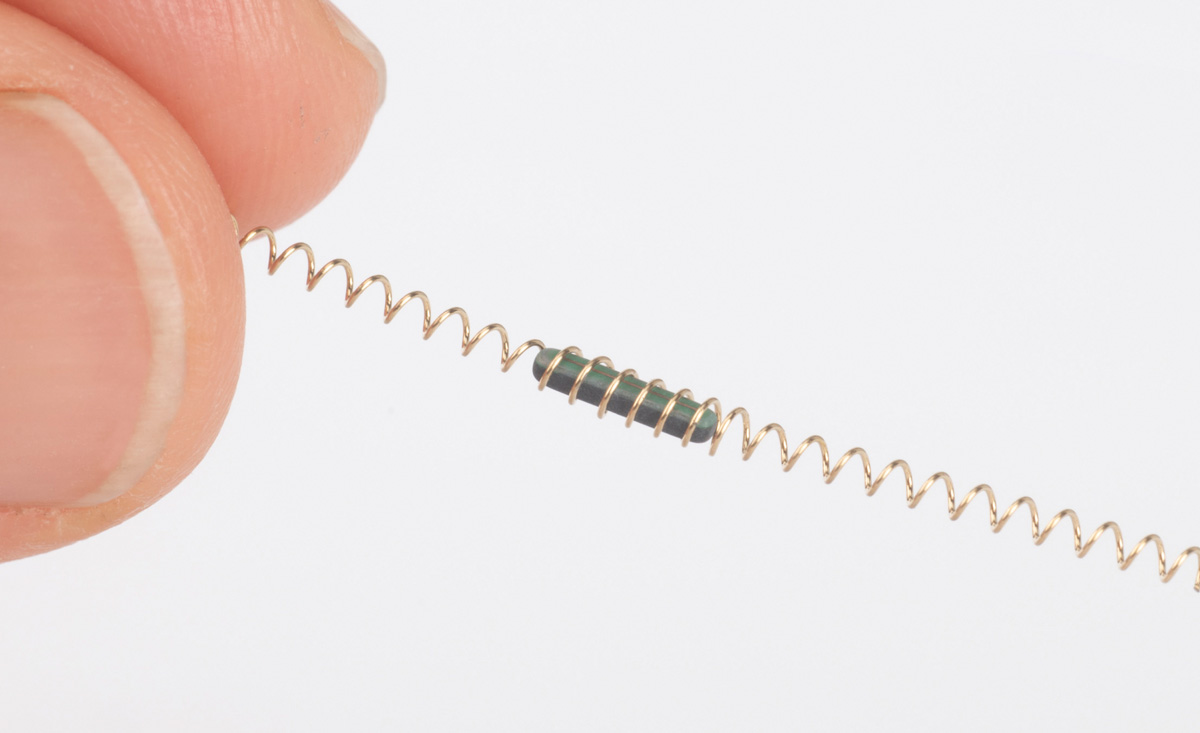

However, there was an issue with conventional RFID tags. The IC and antenna used for information transformation and wireless power supply were joined by soldering. Accordingly, if used by being embedded into a tire, the antenna expands and contracts depending on vibrations during driving. The excessive load on joints as a result of that may lead to breakage and a loss in the ability to communicate. It was necessary to realize a structure in which power can be supplied without contact to solve this issue. Accordingly, Michelin searched for a solution to this issue.

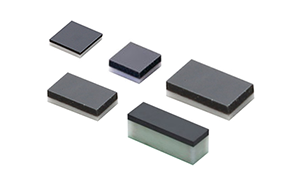

It was Murata's MAGICSTRAP® RFID technology that caught the attention of Michelin as it wrestled with this issue. MAGICSTRAP® is a technology that realizes miniaturization and improved robustness. It does this by embedding into one module a special matching circuit and antenna to optimize the communication and power supply performance with the IC. Murata exhibited MAGICSTRAP® as an RFID technology that realizes miniaturization and improved robustness at an overseas exhibition on the theme of RFID. We did not exhibit this technology for tires. Nevertheless, Michelin came to talk to us while we were showcasing the fact that various applications of this product are spreading. Michelin and Murata decided to codevelop highly durable RFID technology that can be embedded into tires.

When starting the development project, we expected to face three issues in the process of realizing the vision as seen by Michelin: a long-term development period commitment, the high reliability that can be applied to embedding RFID tags into tires, and the provision of a large number of samples. The technology to embed RFID into tires with the expectation that it will be used over their entire lifecycle was a development theme that we at Murata tackled for the first time. However, we decided to flexibly respond without sticking to precedents. We were able to clear each demand in the end.

For this project, we formed a dedicated team committed to long-term development. This team consisted mainly of young engineers with a willingness to take on challenges without being overly fixated on existing technologies. As a result, we established a structure whereby those in charge, who are familiar with the process of projects from the initial development stage to mass production, worked on development consistently while steadily accumulating results. Matsumoto of the Hardware Product Development Section, who participated in the project as a designer, recalls that close mutual understanding led to the success of this project: "The designers directly explained and discussed the design intentions, the validity of the selected technologies, and other matters instead of just conveying to the other party surface-level technologies in the codevelopment with Michelin. That enabled us to smoothly reach a consensus during the project."

Moreover, we added further improvements to MAGICSTRAP® to satisfy high technical demands such as the high reliability that can be applied to being embedded into tires. In addition, we reduced the module size to 6 mm × 1 mm × 1 mm while maintaining good electrical characteristics to minimize the effect on tires due to RFID being embedded into them. There was also a request to extend the communication distance. Therefore, we optimized the product by introducing custom parts. Yabuhara of the Hardware Product Development Section who was primarily responsible for design talked about the factors that made it possible to clear difficult technical issues: "We received appropriate advice from in-house experts with specialized knowledge in each field in addition to advice from the designers who were directly involved in the development. That allowed us to clear the issues."

Furthermore, we improved production efficiency by developing a dedicated batch sorting jig and sorting software to be able to provide a large number of samples. This is because we did not have the characteristic sorter that was indispensable to produce a large number of products in the stage before mass production was confirmed. This enabled us to deliver a large number of samples in the tens of thousands in a timely manner.

Fukuhara of the Business Development Section, who served as the project leader, gave a summary of the project: "It was an extremely difficult challenge to ensure both miniaturization and electrical characteristics. We repeatedly produced prototypes while discussing with Michelin the many design parameters and manufacturing variations in mass production. At the same time, we made every effort to verify the feasibility of mass production at the manufacturing site. I do not think the project would have been successful without Murata, with our high level in design, production technology, manufacturing, and quality technology for the RFID module we developed.”

We have begun full-scale production on the RFID module we codeveloped. It has already been embedded into more than 4 million tires made by Michelin starting with those for commercial vehicles.

We are aiming for the RFID module we codeveloped this time to spread widely as the de facto standard in the automobile tire industry. We also plan to proceed with proposals to tire manufacturers other than Michelin in the future. Prior to that, Murata will also support the activities of the working group in RAIN RFID (a UHF band RFID industry group) and the guidelines established by the ISO.

Murata presented RFID tags to be embedded into tires to the world for the first time at a car electronics technology exhibition held at Tokyo Big Sight in January 2022. We took that as an opportunity to start activities to promote them to tire manufacturers both in Japan and overseas. Yamada of the Business Development Section had the following to say: "It is not possible to embed RFID into tires with the sense of affixing RFID to cardboard or pallets. This is because the inside of tires contains metal materials that interfere with RFID communications such as bead wires and belts. The communication characteristics change significantly by embedding RFID into rubber materials. Murata has extensive wireless knowledge and an evaluation environment. Therefore, we would also like to provide support for optimal embedding methods and customer evaluations without sacrificing communication characteristics with respect to tires." Moreover, we have strengthened the functions required for tire supply chain management with our id-BridgeTM RFID software. That will contribute to the implementation of RFID across the entire tire industry, including automobile manufacturers and the aftermarket, as a total solution.

Minato MIRAI Innovation Center, the largest R&D base in the Kanto region, opened "MURATA MIRAI MOBILITY" from May 2021 as an automotive solutions exhibition area to showcase the relationship between the electrification of automobiles and Murata. Sakai of the Business Development Section is also working on future exhibition plans: "We plan to showcase tires embedded with the RFID we codeveloped with Michelin in the exhibition area in the future. We are also preparing a demonstration environment for id-BridgeTM software. Therefore, I hope that many customers will visit in addition to tire manufacturers."