Thermistors (Temperature Sensors)

PRODUCT FOCUS

AEI by Dempa Publications, Inc., August 2017

Smart factory has been introduced increasingly. “Industry 4.0” is suggested by German government and approach speed up automation process and highly efficiency of factory operation. The factory automation equipments such a PLC, Controller, Motor and Sensor are expected to increase drastically due to factory automation trend, and connections between equipment grow more complex, therefore, miss-wiring is also increased as increasing connection between controller and sensor, mis-wiring is sometimes occurred by human error and abnormal current is flowed into I/O port. If abnormal current is occurred, I/O port will be broken. This is the one reason of malfunction. If malfunction is occurred, production line will be stopped and products will not be produced. Therefore, it is important for factory automation to protect I/O port. Ceramic PTC technology makes it possible to protect FA device with resettable function and high reliability from over current.

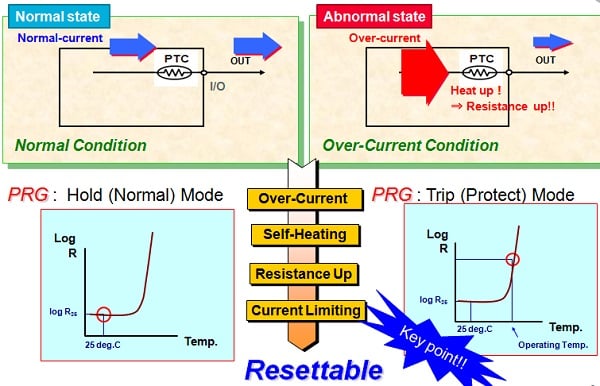

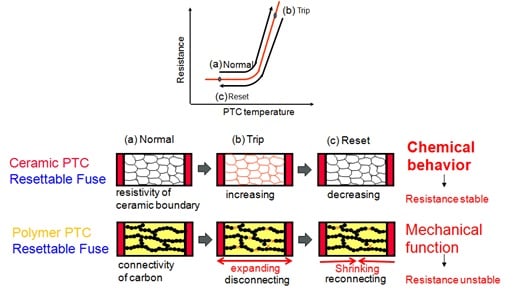

General PTC as over-current protection is shown in Figure 2. PTC operation is a similar to a fuse. During normal operation, the resistance value of PTC is steady. Once inrush current passed on PTC device, the PTC resistance increase due to heat-up by itself, and then inrush current decrease immediately. And, PTC has a feature of resettable protection as many times as needed.

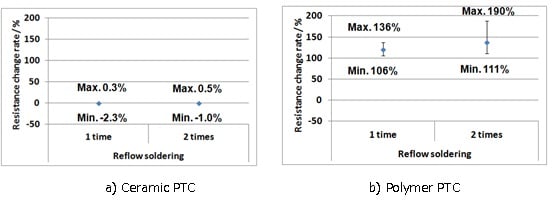

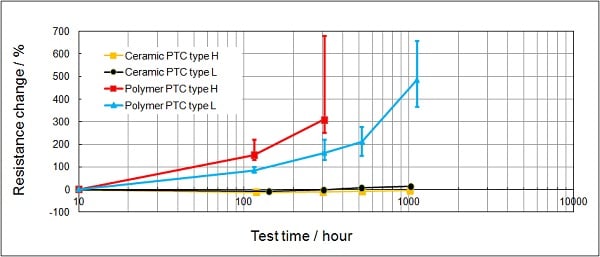

Figure3 shows resistance change after reflow soldering. Polymer PTC resistance reached maximum 190% change after two times of reflow soldering. On the other hand, Ceramic PTC resistance is very stable and their change rate is -1 to max.0.5% with two times reflow soldering.

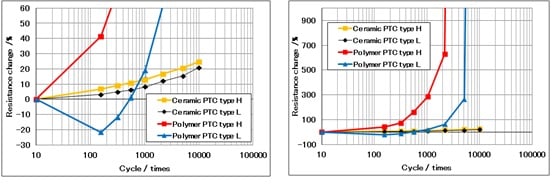

Figure4 shows intermittent load test at room temperature. The resistance change rate of Polymer PTC increased over 40% after 100 cycle road, However Ceramic PTC has stable change rate.

Figure5 shows dump load test at high temperature. The resistance change of Polymer PTC is more than 100% increased at 100 hours. Ceramic PTC has very stable resistance change rate.

As shown, Ceramic PTC has stable reliability in soldering and load test. We note again that Ceramic PTC and Polymer PTC has same Temperature-Resistance characteristic. However, the mechanism of resistance change is different. Ceramic PTC resistance change due to its chemical behavior. In detail, resistance of ceramic boundary increase significantly with increasing temperature at trip state. It can get back to the original value without hysteresis completely. On the other hand, Polymer PTC realizes resistance change due to mechanical change. Polymer PTC is composed resin and connectivity carbon chain. At trip state, its resistance increase due to cut off carbon chain with expanding resin. At reset state, its resistance reduces due to reconnect carbon chain with shrinking resin. However, all of carbon chain cannot reconnect , then resistance keep higher value with hysteresis.

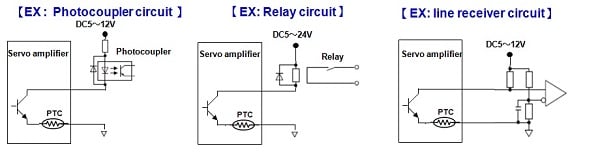

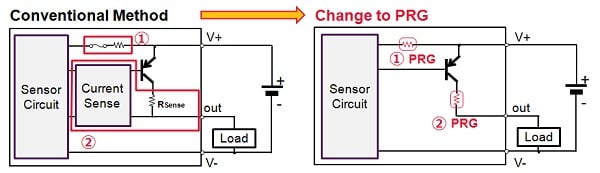

In factory automation, general open-corrector circuit with switch device such a Transistor is used on I/O line for PLC, PAC, Servo drive, inverter and sensors. Ceramic PTC can protect switch device from inrush high current with higher reliability and more safety.

Murata have developed multi layer type of Ceramic PTC at the first time in the world. It technology realize higher hold current with 30V to meet 24V as standard voltage in factory automation market.