Capacitor

Capacitor Guide

This article is a continuation of "Evolving Capacitors: Multilayer Ceramic Capacitors, Part 1 Trend (part 1/2)".

Please read "part 1/2" first for an overall perspective.

As mentioned above, multilayer ceramic capacitors are arranged around microprocessors, DSPs, microcomputers, FPGAs, or other semiconductor devices to support the proper operation of these devices. The number of multilayer ceramic capacitors used in an electronic device is enormous. For example, about 730 units are used in a notebook computer and about 230 units can be found in a mobile phone, while digital TVs and car navigation systems both use about 1,000 units (Table 1).

| Electric device | Number of monolithic ceramic capacitors used |

|---|---|

| Notebook computer | 730 |

| Mobile phone | 230 |

| Digital camcorder | 400 |

| Digital TV | 1000 |

| Car navigation system | 1000 |

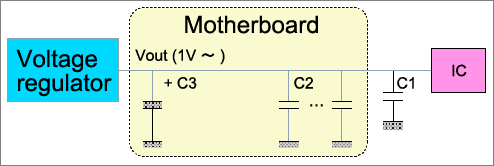

Multilayer ceramic capacitors have two main roles. First, they support the power supply for semiconductor devices. In general, the current required for a semiconductor device varies significantly depending on the operating conditions. In some situations, a large amount of electric power may be suddenly required. The power supply circuit (DC-DC converter, etc.), which is located relatively far from the semiconductor device, will fail to quickly respond to an abrupt load change. To cope with this problem, electric power is stored in a capacitor mounted close to the semiconductor device and supplied from there (Figure 1).

A number of decoupling capacitors are mounted around a semiconductor device. These capacitors play two roles. One is to supply power to the semiconductor device. The other is to shunt the noise component to the power/ground layer. Note that three types of capacitors are mainly used for decoupling. They are tantalum electrolytic capacitors, high-capacitance monolithic ceramic capacitors, and monolithic ceramic capacitors with an exceptionally low equivalent series inductance (ESL).

A number of decoupling capacitors are mounted around a semiconductor device. These capacitors play two roles. One is to supply power to the semiconductor device. The other is to shunt the noise component to the power/ground layer. Note that three types of capacitors are mainly used for decoupling. They are tantalum electrolytic capacitors, high-capacitance multilayer ceramic capacitors, and multilayer ceramic capacitors with an exceptionally low equivalent series inductance (ESL).

Another function of multilayer ceramic capacitors is the elimination of the noise component, which can cause electromagnetic interference (EMI). In a sense, it acts as a filter. By utilizing the small high-frequency impedance of a multilayer ceramic capacitor, only the high-frequency noise component can be shunted away to the power/ground layer.

Generally, capacitors featuring the former function are called decoupling capacitors, while those having the latter function are called bypass capacitors. Now, both functions can be fulfilled at the same time by the introduction of high-capacitance multilayer ceramic capacitors.

The second most pervasive application after decoupling and bypassing is smoothing filters arranged at the output of DC-DC converters. Initially aluminum and tantalum electrolytic capacitors have been adopted for this purpose. However, starting in the late 1990s, multilayer ceramic capacitors came into use in order to reduce the size and thickness of electronic devices.

It is largely due to the efforts of manufacturers of power semiconductor devices that multilayer ceramic capacitors are now available for this smoothing filter function. A capacitor serving as a smoothing filter constitutes part of the feedback control loop of a DC-DC converter. Therefore, if the equivalent series resistance (ESR) is too low, the phase margin of the control loop decreases, resulting in the DC-DC converter not operating in a stable manner.

Meanwhile, electronics manufacturers have strong demand for smaller and thinner DC-DC converters. To meet this demand, power semiconductor device manufacturers made it possible to use multilayer ceramic capacitors by improving the control circuit in DC-DC converter ICs. Around 2000, power semiconductor device manufacturers began selling the new DC-DC converter IC to electronics manufacturers, making the case that multilayer ceramic capacitors can be used in the IC.

At present, the decoupling and smoothing filter applications alone reportedly account for about 70% of the multilayer ceramic capacitor market. Other typical applications include high-frequency filters, impedance matching, and temperature compensation.

Murata provides demonstrations and holds seminars highlighting examples of problem-solving that illustrate easy-to-understand methods for replacing electrolytic capacitors with multilayer ceramic capacitors.

In addition, we also provide design support to help ensure stable DC-DC converter operation when using multilayer ceramic capacitors for smoothing applications. Please feel free to contact your Murata sales representative with any inquiries.

Please visit the following website for further information.

※Indicated company and product names are the trademarks or the registered trademarks of each company.

* The content of this article listed in the from February to March 2010 issue of "Tech On!" Nikkei Business Publications, Inc., was restructured.

* For more details on the Murata Manufacturing multilayer ceramic capacitors, please refer to the following:

▼Capacitor WEB site

The information presented in this article was current as of the date of publication. Please note that it may differ from the latest information.