DX×Murata: The future of manufacturing that is evolving through DX

ECM Reform through the Design Work Improvement Project

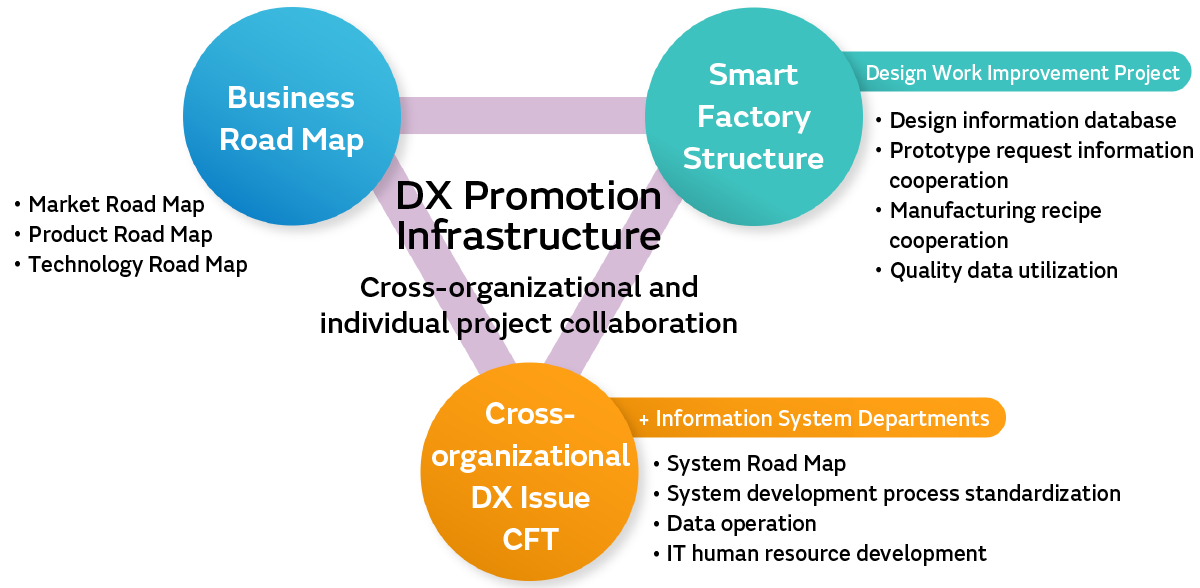

The engineering chain refers to the series of work processes starting from planning and R&D to the transfer of control to the mass production factory through product design, construction method development, equipment design, and more. Activities aiming to shorten the lead time to commercialization and to improve development capabilities and quality by optimizing this engineering chain are called engineering chain management (ECM). ECM is attracting attention as a keyword for DX in the manufacturing industry. Kondo, who promotes ECM reform on a company-wide basis, and Muraoka, who tackles DX through the Design Work Improvement Project, explain here the keys to promoting DX in the ECM field.

Improving Efficiency of Monozukuri through DX Is Extremely Important in the Medium to Long Term

--First, please tell us the background that led to this project.

Kondo: “Murata has set drastically strengthening the ECM axis as a medium-term policy. Accordingly, we have started full-scale initiatives on ECM. It is difficult to proceed with reform all at once when we have so many divisions. Therefore, we are at the stage where the Communication Module Division / RF Device Division and EMI Filter Division are taking the lead in starting work on ECM initiatives. I want to make this medium-term period three years when we consider the potential to deploy these ECM initiatives to other divisions upon first building solid foundations. The department to which I belong is playing the role of leader of this on a company-wide basis.”

Muraoka: “The Communication Module Division has been promoting reform of high-frequency PCB design work. We manufacture high-frequency PCBs at multiple sites. In addition to the sense of the scale of this being large, the quality required is rising and needs are also growing as smartphones become increasingly sophisticated. Under such circumstances, we were aware that realizing efficient monozukuri through DX would be extremely important in the medium to long term.”

Kondo: “The concepts of digital threads and digital twins have emerged recently. There is also a major trend to link information about products and to then attempt to reproduce things that exist in the real world in the digital space (cyberspace). There are not many precedents for company-wide initiatives in the ECM field in Murata. Therefore, I think it is very meaningful that we were able to take the first step. I belong to an information systems department, so, of course, I am conscious of digital. However, I think the key is to first work prioritizing a review of the way work itself should be performed and to then ask how to utilize digital as a means to that.”

--Murata has been working on digitization for some time. Have you felt any issues with that?

Muraoka: “We introduced various systems to implement improvement. However, we had an issue with whether we were able to utilize the data. We had accumulated data, but we lacked the perspective of how to utilize it and how to connect it. That is a trap into which many companies fall.”

Kondo: “Many departments are involved in the ECM field and the work is also diverse. Therefore, I feel it inevitably takes time to solve issues. For that reason, I consciously promote small success / quick success initiatives that produce results quickly even if small on a simultaneous and parallel basis by introducing automation tools, visualization tools, and other tools in addition to themes we work on by spending a lot of time on them. Major trends may also begin starting with small successes. We hope to be able to promote initiatives while allowing designers to experience the effects with this two-stage approach.”

Embodying Engineers’ Ideas of ‘I Wish It Was Like This’

--Please tell us about the project launch flow.

Muraoka: “First, we recognized anew the form of business that we would like to specifically aim for such as contributing to value in society and life as stated in our business policy as our goal image. After that, we shared the strategy and image of achievement to produce the concept.”

--How was the concept set?

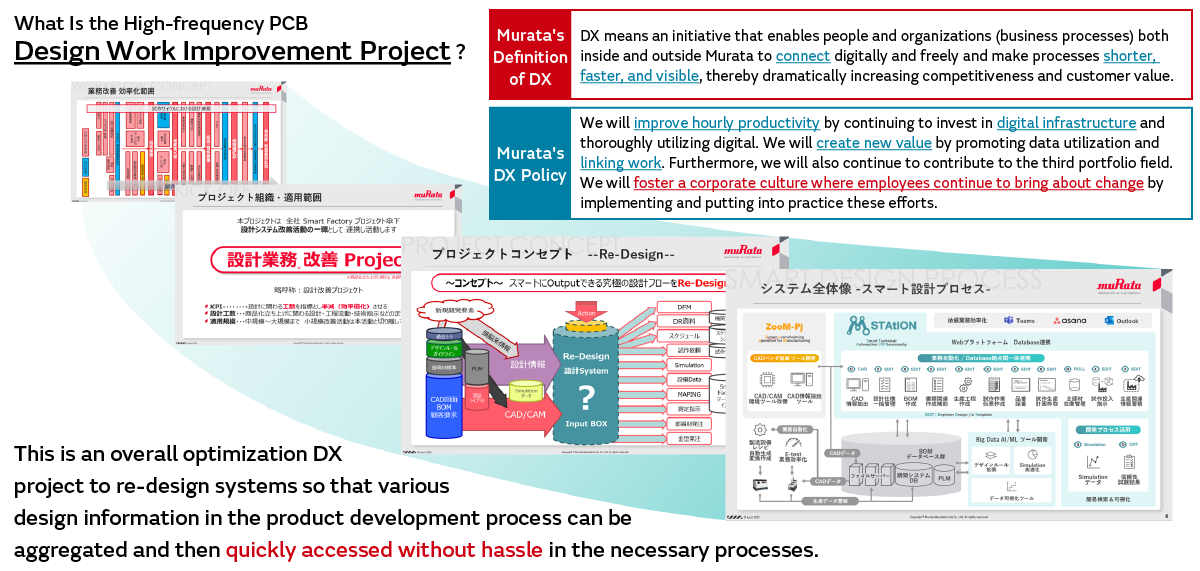

Muraoka: “We wanted to embody the ideas of many of our engineers of ‘I want to eliminate unnecessary tasks’ and ‘I wish it was like this’ as the premise. Accordingly, we came up with the ‘Re-Design’ concept to simplify complex design work processes and to be able to retrieve necessary information from one database. We embedded in that an intention to create a design process with a high degree of freedom in changing and evolving work, for each employee to be able to experience achievements and growth, and to create a model case in Murata.”

Kondo: “ECM reforms for high-frequency PCBs are advanced and leading the way looking at the whole of our company. I hope we can revitalize discussions on the ideal state for Murata upon understanding work sites while listening to the situation of PCBs.”

Centralizing Dispersed Data and Significantly Reducing the Design Workload

--Please tell us about the details of the Design Work Improvement Project.

Muraoka: “Before the project started, although we had a huge amount of data, it was scattered. Accordingly, we proceeded with the idea of consolidating the dispersed data into one database and re-making it so that it would be possible to retrieve the data with one action. Our goal is to significantly reduce the workload involved in design by organizing data such as design specification batch management, production process creation, and main component inventory control on a Web platform.”

--Is this like collecting together ingredients scattered in different places into one location when cooking?

Muraoka: “I think that image is close. To add to that, it is also about automating / simplifying the process instructions: This type of potato is best if making meat and potato stew. It should be about this temperature. We should cook it for so many minutes.”

Importance of a Management Team with Enthusiasm for Transformation

--What kind of future lies ahead once you have launched this project?

Muraoka: “In addition to dramatically increasing work efficiency, we are also looking to improve quality. For example, our dreams are getting bigger and bigger such as by analyzing the degree of impact design information has on malfunctions and improving quality through making prototypes in the cyberspace. However, processes in the manufacturing industry are constantly evolving and changing. Therefore, I don’t think there is a complete end goal for this project.”

Kondo: “Information system members in the monozukuri field are working on the Design Work Improvement Project. Accordingly, this project is characterized by a strong awareness of cooperation with manufacturing. That is one of its greatest strengths. We would like to take on the role of absorbing what is important from examples in high-frequency PCBs as company-wide assets and then deploying them to other divisions.”

--You have cooperated and collaborated with other departments in promoting this project. Did you have any difficulties working across organizations?

Muraoka: “That was a very difficult part of this project. The most important thing in DX is that the department that wants to obtain results should work to achieve them proactively. However, the key is also a promotion structure that allows for the understanding and direct involvement of the management team. I realized that this project would not come to fruition if the management team did not actively drive it and if they did not have the enthusiasm and resolve to work on DX.”

Kondo: “We are promoting the cultivation of an organizational culture that utilizes digital and the development of DX human resources as a set for ECM reform in the EMI Filter Division. When promoting such initiatives, in addition to those who deeply understand the work and members in information system departments, I believe that we need those playing such roles as business translator to serve as a bridge between the two. I want to advance this project involving enthusiastic employees who will drive DX promotion at work sites.”

How to Share, Utilize, and Connect Knowledge?

--Finally, please tell us the realizations you have come to in this initiative and your aspirations for the future.

Kondo: “Murata has accumulated a variety of data and information. However, I still think there is more that we can work on in terms of utilizing that data and information in development and design work. In particular, it is important to work on this knowledge upon forming an image of the specific utilization settings instead of accumulating knowledge in advance. I want to improve accuracy by repeating the cycle of verifying whether the knowledge is truly useful over and over again. Our goal is to shorten the lead time of product development and to improve quality by ensuring designers become able to devote themselves to work to obtain new findings with the utilization of knowledge.”

Muraoka: “The major issue for Murata’s engineers was wastefulness from losing time spent on tasks that could otherwise be made more efficient. I believe this project also has value to produce creative ideas with their true value. Of course, enthusiasm is vital. It think it is essential for DX to have the enthusiasm to incorporate new things and evolve while the manufacturing industry continues to change.”