High-Frequency Noise Suppression in Automotive Equipment Using Common Mode Choke Coils

The current circumstances of noise suppression on in-vehicle equipment power supply lines

Markets have been expanding for in-vehicle equipment for the application of technologies including ADASs, automated driving, V2X, and telematics. Because these applications involve the handling of large amounts of data, the signal processing to handle this data on the equipment are being made to reach higher and higher speeds. At the same time, with the rise in the number of components on this equipment, the density of the mounted components on the equipment increases and creates a need for the miniaturization of these components.

There has also been an expansion in the application of wireless communication capable of communicating data at high speeds. The application of this type of communication technology comes with the need to reduce higher frequency noise.

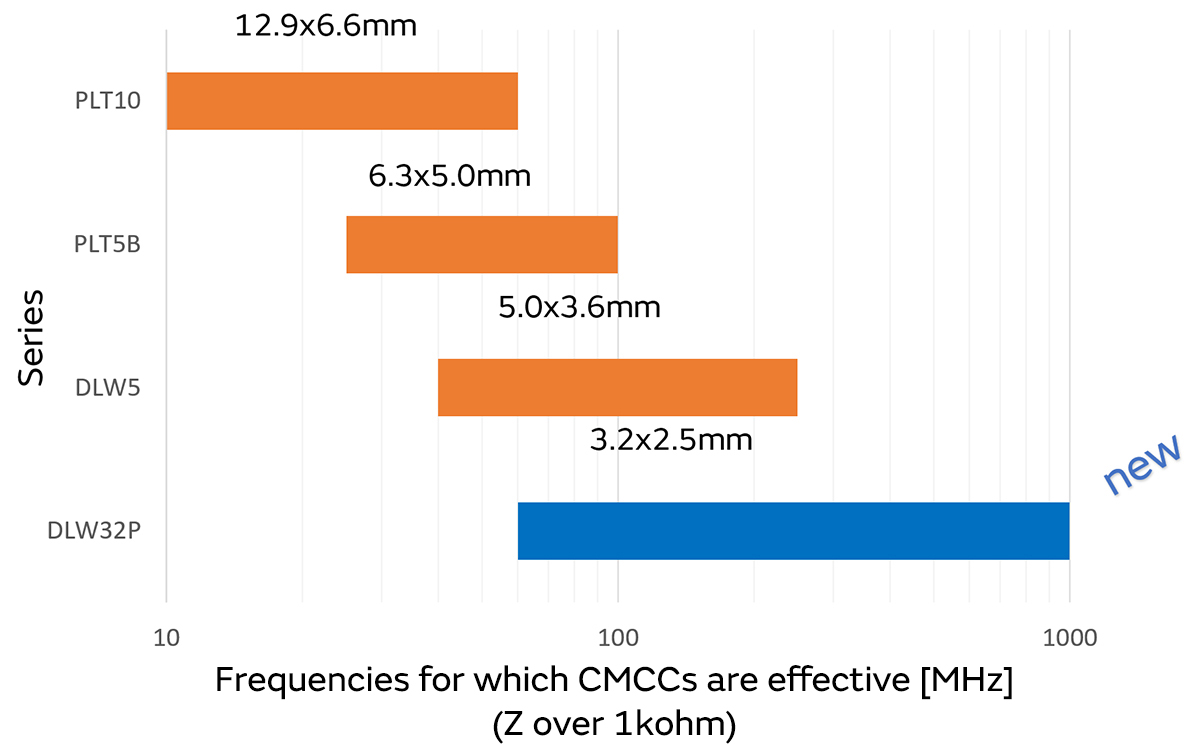

Common mode choke coils are effective in reducing noise generated on power supply lines. With conventional in-vehicle equipment, the main targets for noise suppression on power supply lines were noise in the AM and FM frequency ranges, and larger components were used to suppress low-frequency noise. However, with in-vehicle equipment becoming more sophisticated, there is also the need to prevent noise in frequencies higher than the AM and FM ranges.

Murata Manufacturing has commercialized DLW32PH122XK2, a common mode choke coil designed for use on power supply lines. This compact CMCC responds to the market trends and is suited to reducing higher frequency noise. We explain the noise suppression effects of DLW32PH122XK2 in this article.

Generated noise suppression by common mode choke coils

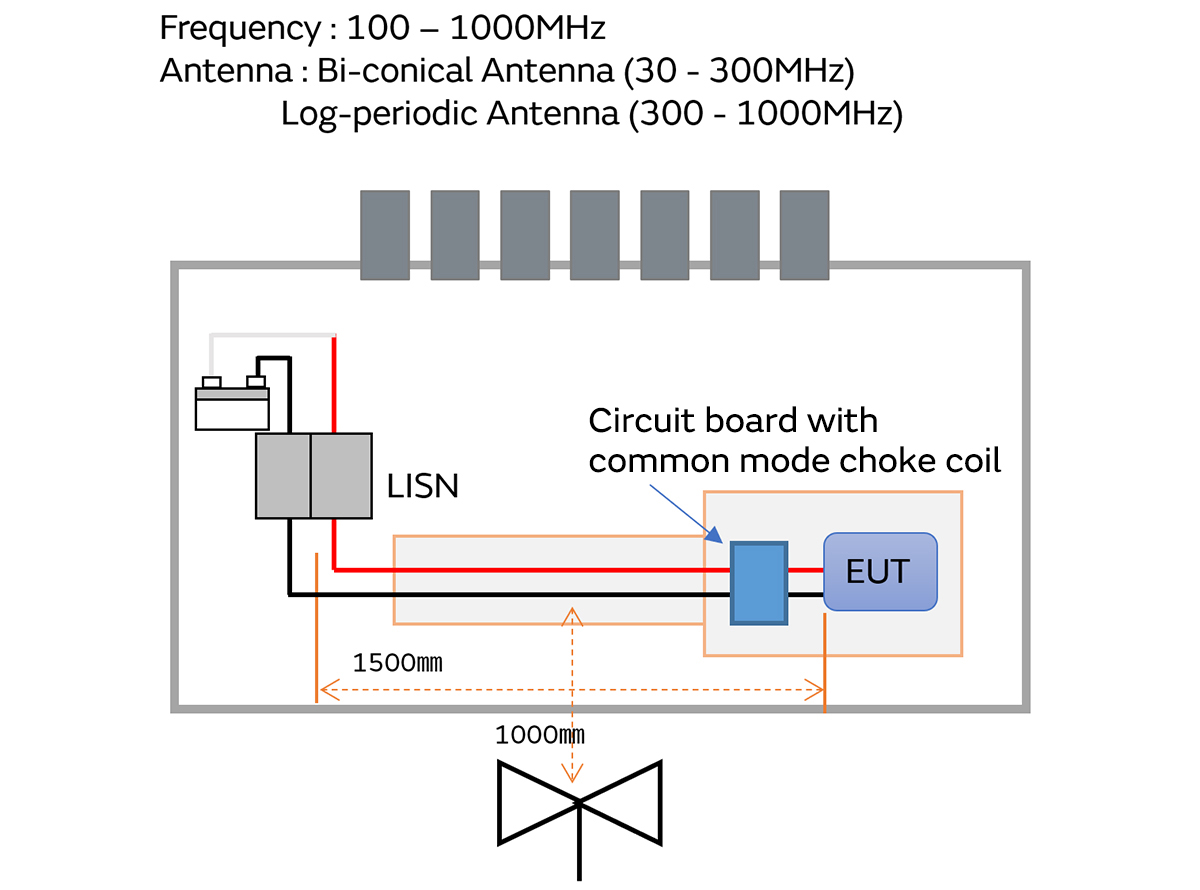

Using a measurement system like the following, we measured the amount of noise generated by the EUT from the power supply cable acting as an antenna and verified how much noise could be reduced by the common mode choke coil.

[Measurement system]

Based on CISPR 25, an international standard for automotive component noise

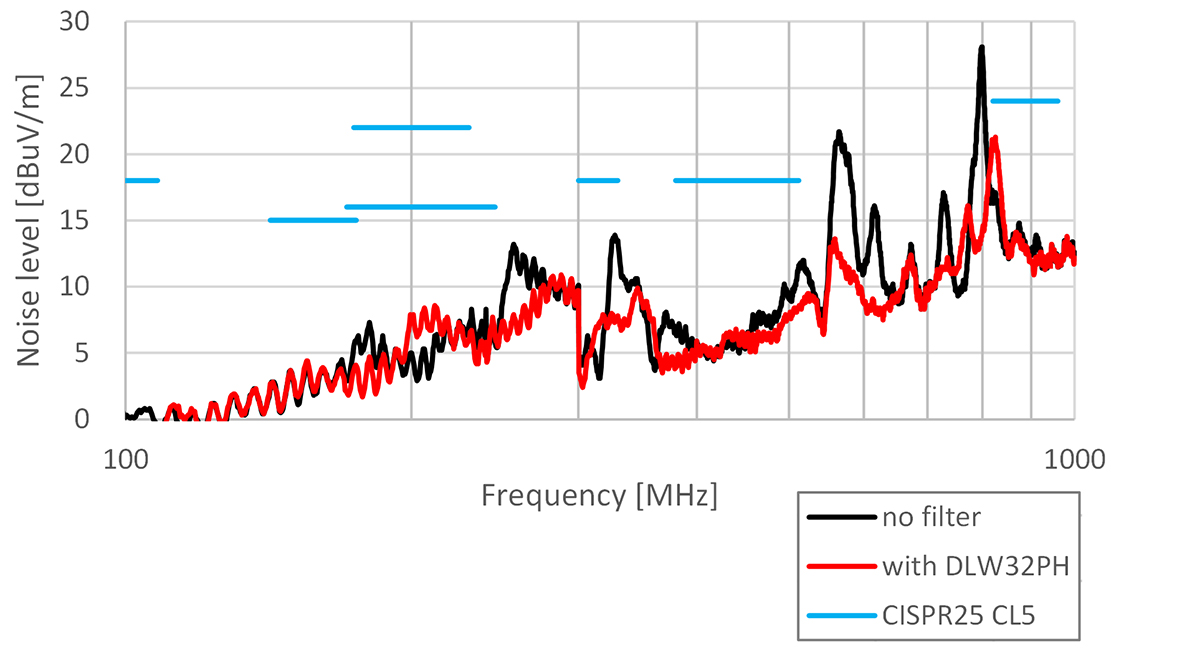

In the EUT used for the measurements, the frequency of the noise generated was in the 200MHz-800MHz range. However, by incorporating DLW32PH122XK2, the noise in this frequency range was greatly reduced.

Noise suppression by common mode choke coils in BCI tests

BCI tests are tests that verify the amount of resistance to external noise.

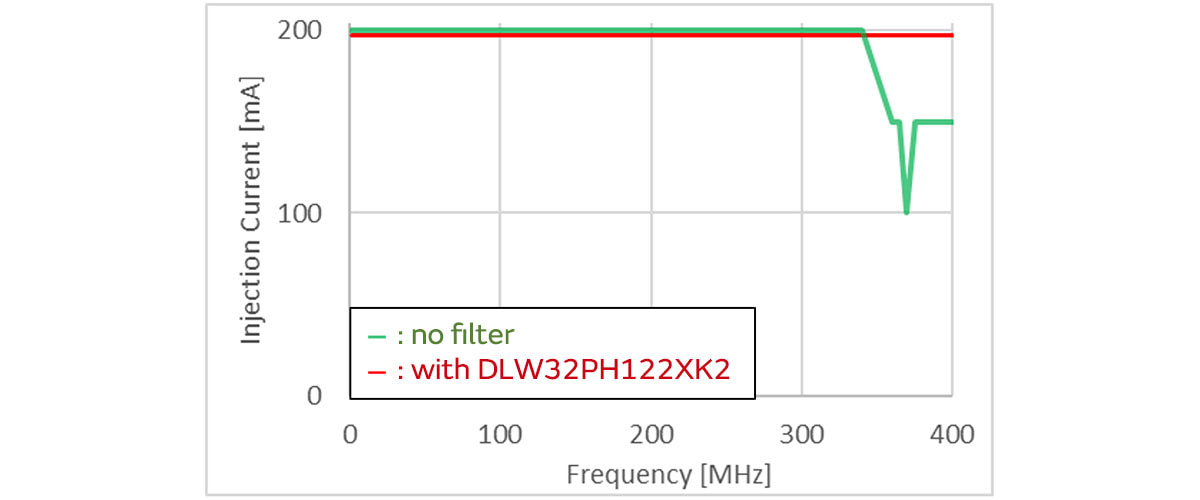

If external noise enters the EUT, the EUT can malfunction. If there is low noise resistance, even lower frequency noise can cause malfunctions. We measured the amount of improvement that could be achieved through the incorporation of DLW32PH122XK2.

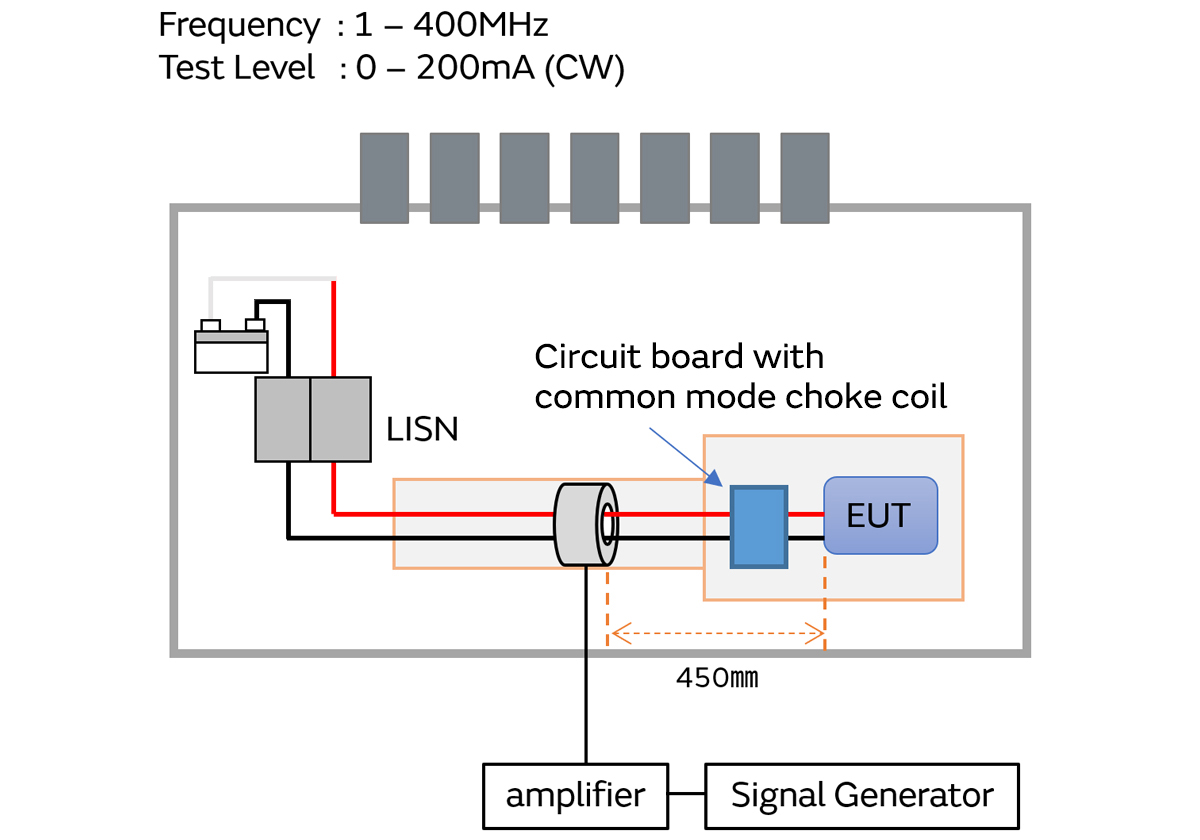

[Measurement system]

Measurements were made through the BCI test substitution method as specified in the international ISO 11452-4 automotive component noise testing standards.

When 360 to 400 MHz frequency noise was injected into the EUT used for measurements in this study, the DC/DC converter stopped switching, resulting in a malfunction that caused the output voltage to drop to 0 V. Incorporation of DLW32PH122XK2 significantly reduced the noise in this frequency range and improved noise tolerance for the prevention of malfunctions.

Conclusion

- AM/FM frequency noise suppression had been sufficient for noise suppression on in-vehicle equipment in the past, but recent advances in in-vehicle equipment technology has made it necessary to also remove higher frequency noise at frequencies of several hundred MHz.

- DLW32PH122XK2 common mode choke coils are superior to conventional common mode choke coils used on power supply lines because of their high-frequency noise suppression performance and ability to reduce noise at frequencies of several hundred MHz.

Part number | size | rated | impedance | impedance | rated |

|---|---|---|---|---|---|

3.2×2.5×2.5mm | 60Vdc | 900Ω typ. | 1200Ω±20% | 1200mA |

Refer to: Circuit board design that addresses the issue of noise paths

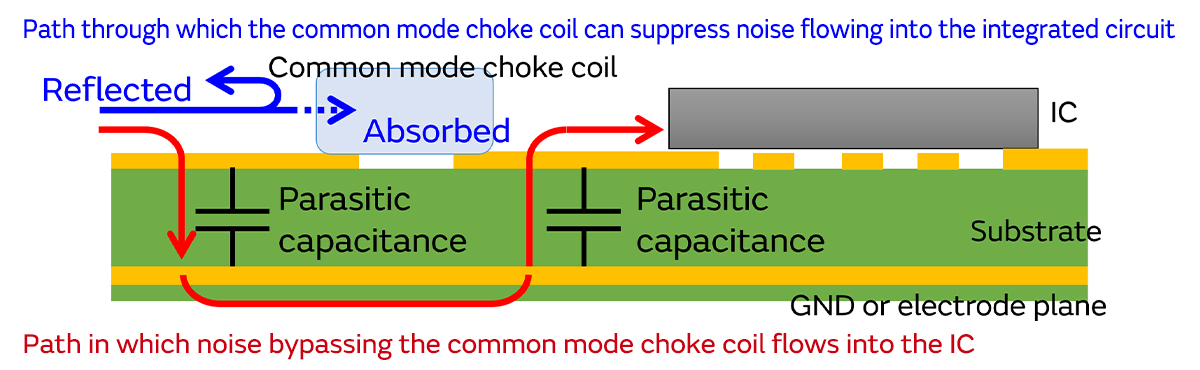

Common mode choke coils can effectively eliminate noise from power supply lines. However, the proper circuit board design is critical to achieve this result.

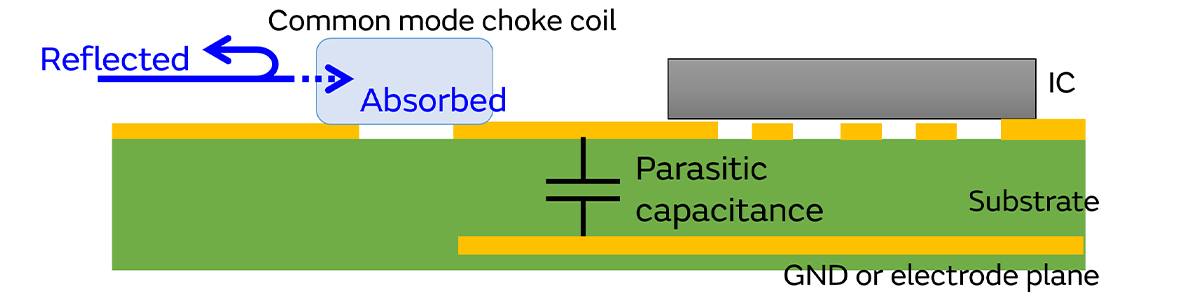

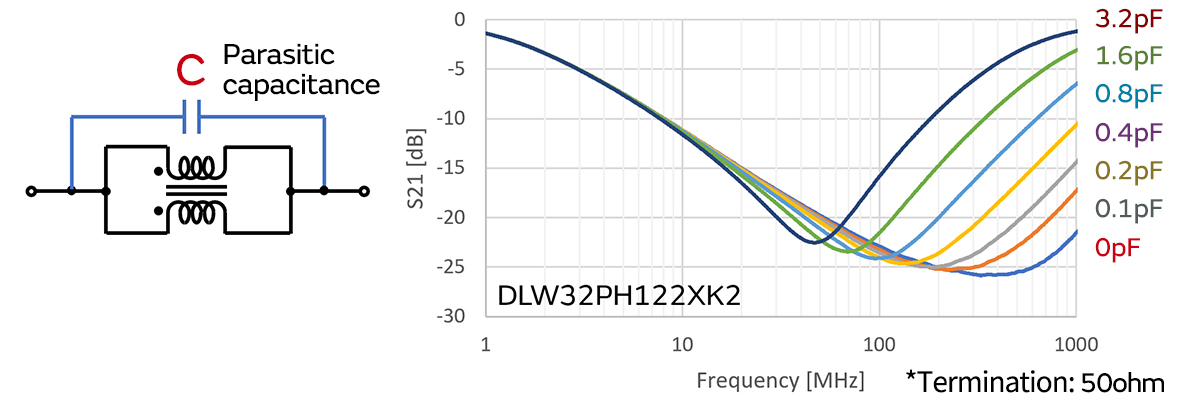

If there is a ground or power plane as an inner layer of the circuit board, parasitic capacitance is generated between the ground and power plane and the pattern on the top layer of the circuit board. When the ground/power plane is flat and uniform, noise propagated through the pattern passes through the ground/power plane via parasitic capacitance. After it passes through the common mode choke coil, it returns to the pattern via parasitic capacitance, bypassing the common mode choke coil as a result. This phenomenon reduces the efficacy of the common mode choke coil.

An issue like this can be solved by removing the ground/power plane directly under the component as shown in the figure below to block the ground/electrode plane bypass path.