Ultrasonic Sensors

CEATEC 2023

INDEX

Ultrasound transmission metamaterial that enables ultrasonic waves to pass through substances

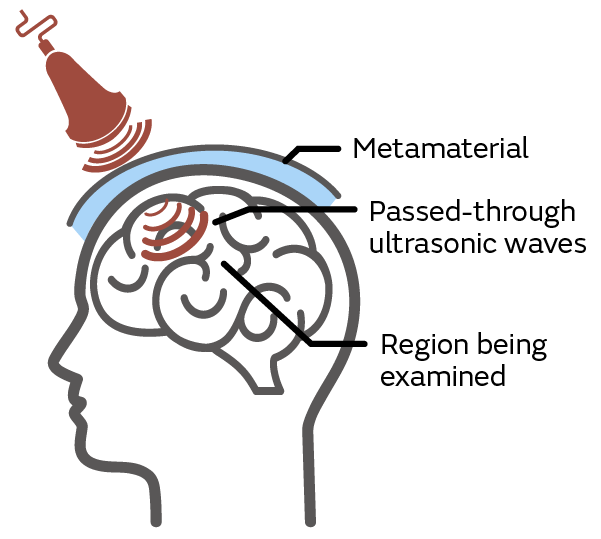

Using an ultrasonic scan to examine a brain encased in the cranium

Installing ultrasonic sensors without detracting from the design attractiveness of automobiles

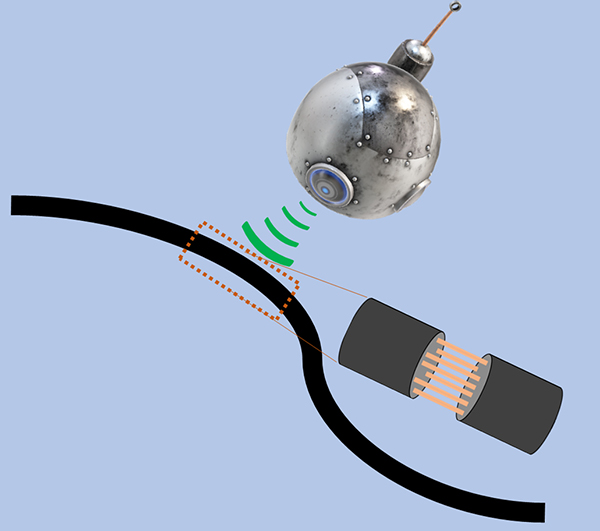

Noncontact inspection of the interior portion of underwater cables within the cladding

Even among people who never miss their yearly medical checkup, very few undergo regular brain examinations. CT scans or magnetic resonance imaging (MRI), which provide a direct view of the state of the brain, utilize equipment that is large, expensive, and requires a high level of specialized expertise in addition to medical knowledge to operate safely. As a result, such examinations are only available at large medical institutions.

Murata Manufacturing (Murata) has developed a technology that has the potential to enable ultrasonic scans, which are presently used to view the fetus within the uterus, to be used to view the brain within the cranium. It may be possible, by placing a sheet with a unique structure called an “ultrasound transmission metamaterial” on the skin of the patient’s head, to make the cranium transmissive to ultrasonic waves. If this can be achieved, it is possible that a wider range of medical institutions will be able to perform examinations of the brain relatively easily.

Potential fields of application for ultrasound transmission metamaterial are not limited to medicine. In a variety of different areas, such as making automobiles “smarter” and the maintenance and management of social infrastructure, this new technology has the potential to encourage wider utilization of ultrasonic waves. Murata exhibited the ultrasound transmission metamaterial at CEATEC 2023, held at Makuhari Messe from October 17 to 20, 2023. We interviewed Mr. Nishida and Mr. Hussain of the Material Technology Sensor Material Process Development Department, Technology & Business Development Unit of Murata Manufacturing, who were involved in the development of the new technology, about the operating principle behind its unique functionality, as well as possible applications.

--What sorts of things does the technology behind the ultrasound transmission metamaterial make possible?

Nishida: An ultrasound transmission metamaterial is a material that makes obstructions, which would otherwise prevent ultrasonic waves from passing through, transmissive. As used here, the term “metamaterial” refers to a man-made substance that has functionality for realizing behavior not seen in the natural world, with respect to the propagation of waves of magnetism or sound.

Ultrasonic waves are sound waves with a frequency beyond the audible range of the human ear (20 kHz and above). They are used in a variety of areas, ranging from industrial and medical devices to home appliances. Many applications are products that most people will be familiar with, such as fishfinders, ultrasonic cleaners for eyeglasses, and ultrasonic humidifiers. When employed as a sensing medium, ultrasonic waves can be used to detect transparent solid or liquid items or small objects in dark places as well as objects with low reflectance of radio waves. In recent years, ultrasonic sensors have also come into use in automated car parking systems.

Ultrasonic waves can be used for many different applications, but one thing limiting the range of uses is that they are unable to pass through barriers made of materials such as metal or resin to reach objects on the other side. When ultrasonic waves impinge on a substance with an acoustic impedance significantly different from that of the propagation medium (air when detecting objects in the atmosphere), most of them are reflected back and very few pass through. “Acoustic impedance” is an index of how easy it is for sound to be conveyed. It is a small value in the case of air, in which molecules are distributed thinly, and a high value in the case of dense substances such as metal or resin. This is why the boundary between air and a solid barrier is not transmissive to ultrasonic waves.

Note: For a detailed description of “acoustic impedance,” click here.

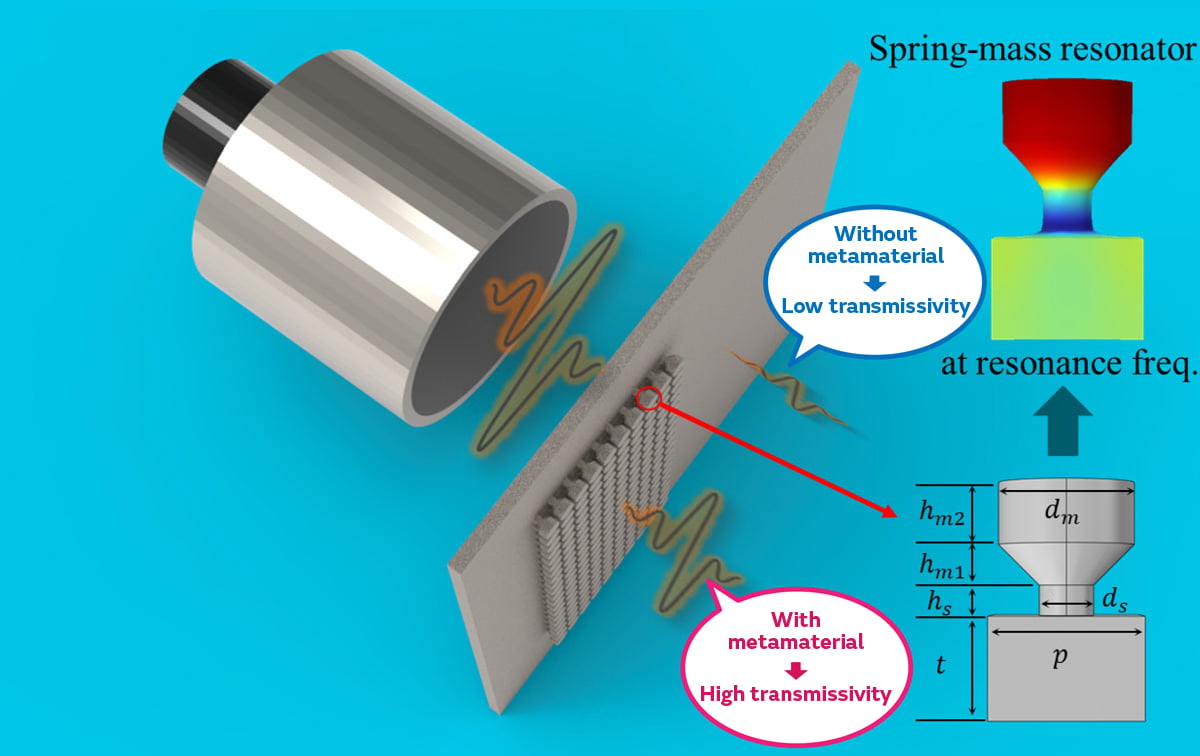

The ultrasound transmission metamaterial developed by Murata incorporates a resonating mechanism utilizing a spring-mass resonator structure. Placed on top of the material constituting the obstruction, it reduces the difference in acoustic impedance, thereby increasing the transmissivity to ultrasonic waves.

--Specifically, what functionality did you achieve when you created a prototype of the ultrasound transmission metamaterial?

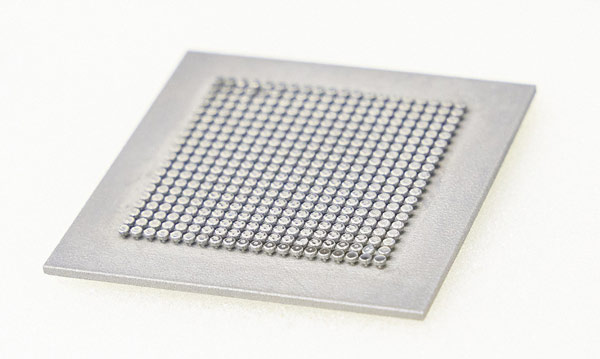

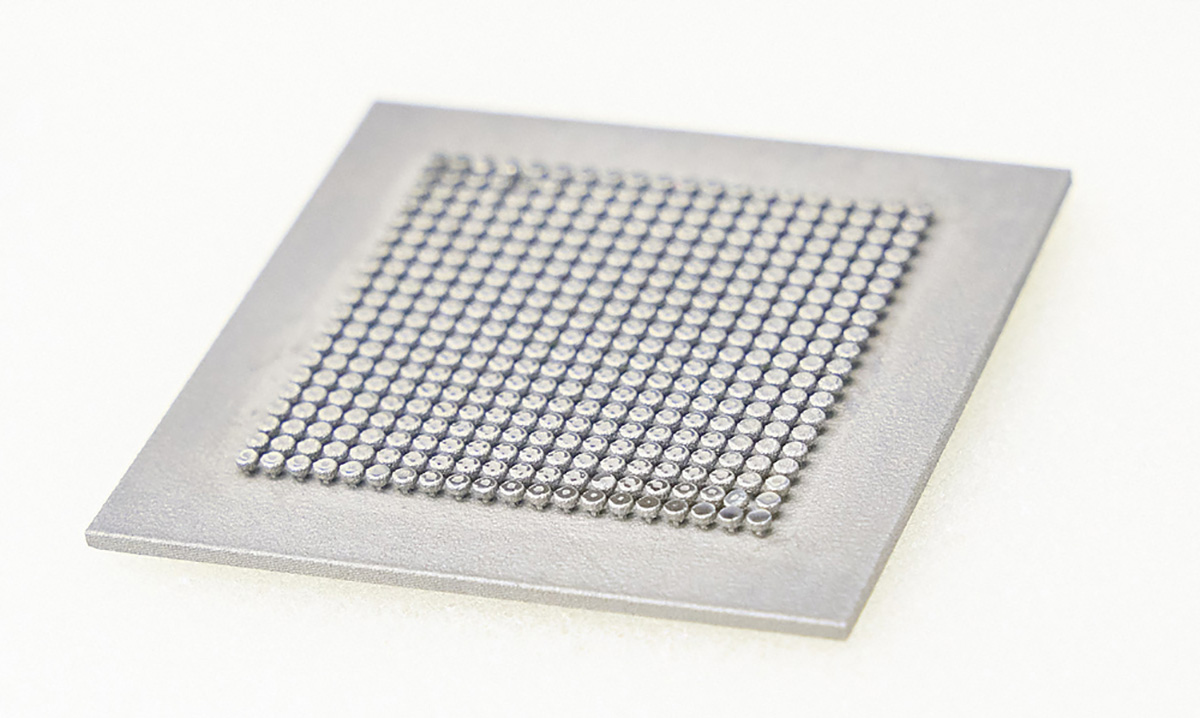

Hussain: The structure of the ultrasound transmission metamaterial developed by Murata consists of “tiny unit cells,” each composed of a weight and a spring, arrayed regularly on a backing sheet (Figure 1). It is designed so that, by adjusting the configuration and size of the weights and springs, the unit cells can act as spring-mass resonators when impinged upon by ultrasonic waves. The unit cells resonate perpendicularly to the direction of the impinging ultrasonic waves, causing an obstruction with a greatly different acoustic impedance to become transmissive and allowing the ultrasonic waves to propagate efficiently.

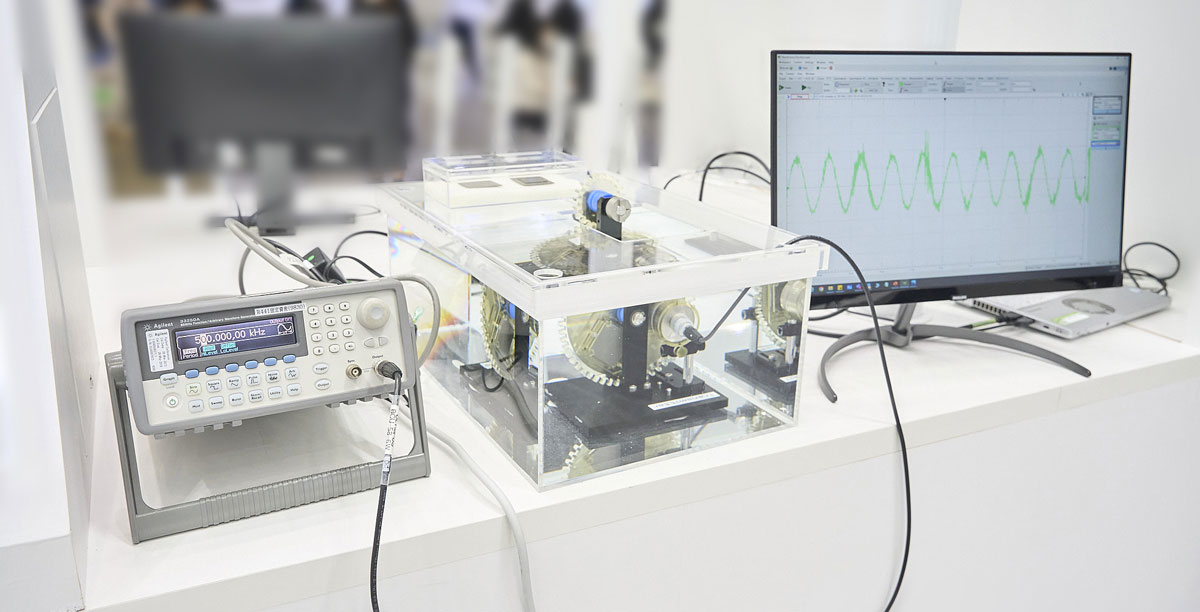

To create the prototype, a 3D printer was used to form tiny unit cells on a stainless steel plate 1 mm thick. This was then immersed in water and ultrasonic waves at a frequency of 500 kHz were directed toward it from a transmitter. The receiver on the other side indicated that we had succeeded in achieving 60% ultrasonic transmissivity. This technology can enable ultrasonic waves to pass through more than just stainless steel plates. It can be applied to a variety of different materials if we can design unit cells matched to the difference in acoustic impedance between the obstruction and the transmission medium.

--What sorts of applications do you envision for the ultrasound transmission metamaterial you have developed?

Nishida: First of all, we envision its application as a material used in medical examinations. In the medical field, ultrasonic scans are used as an examination method to reveal important information that cannot be obtained using X-ray, CT, or MRI scans. A particular advantage of ultrasound scans is that they produce video output showing the movement of the affected part of the body. In addition, unlike examination method such as CT scans that employ X-rays, there is no danger of overexposure to radiation.

But even though ultrasonic scans provide these benefits, ultrasonic waves are not able to pass through bone and can therefore not be used to examine organs or structures that are encased in bone. This means that ultrasonic scans cannot be used to examine the brain, which is encased in the cranium.

The ultrasound transmission metamaterial may make it possible to perform ultrasonic scans of the brain. It is our hope that this will enable detailed examinations to be performed easily, even at smaller medical facilities, while minimizing the burden on the patient.

Hussain: Ultrasonic sensors are used in automotive parking-assist systems, but our new technology will make it possible for them to be installed in places where they are not exposed on the outside of the vehicle. Up to now, it has been necessary to install automotive ultrasonic sensors on the exterior surface of the vehicle’s body. If they are under a cover of some kind, the ultrasonic waves are not able to pass through.

There is no doubt that in the near future automobiles will need to have many different kinds of sensors installed in various places on the vehicle in order to enable autonomous driving functionality. It is possible that for many consumers who love cars, the value as products of models with a large number of unsightly exposed sensors on them will drop. Also, installing the sensors in exposed positions on the body reduces their durability. For this reason, there is demand for technology that will enable ultrasonic sensors to be installed in a way that does not detract from cosmetic appearance or reliability. By using an ultrasound transmission metamaterial, it will become possible to install ultrasonic sensors in places like inside a car’s bumpers.

Nishida: The technology can also be applied in the maintenance and management of underwater cables used for things like long-distance communication and offshore wind power generation. Maintenance and management to ensure the stable operation of underwater cables requires inspection not only of the exterior, but also of the interior portion of the cable inside the cladding. Nevertheless, up to now, there has been no way to check the status of the interior of cables encased in cladding.

Adding an ultrasound transmission metamaterial to the cladding of underwater cables would make it possible to inspect the cable interior without making physical contact, by using underwater drones equipped with ultrasonic sensors or by lowering such sensors from ships. This has the potential to reduce the burden associated with inspections of underwater objects in seas or rivers.

Hussain: In the businesses involved in implementing the newly developed technology in society, I hope we can create a system enabling the design of unit cells optimized for places where ultrasound transmission metamaterials are used, and complete and make available solutions that provide the required results.

Nishida: The three application examples we have described are only some of the candidates we can envision at this point in time. The unique technological characteristics of ultrasound transmission metamaterial will surely expand the range of places where ultrasonic waves can be used and pave the way for many more applications we haven’t even thought of yet. In addition to sensors, applications using ultrasonic waves to process or clean materials may give rise to additional value in the application of the technology we developed.

We still have a lot of work to do refining the new technology for use in actual applications. At the same time, we are working to pave the way for innovative new applications and to attract a wide array of business partners to help with the refinements. If you think your company would be interested in joining us in this effort, please feel free to contact us.

*The content of this article is current as of the publication date. Product specifications and external appearance subject to change without notice.