Inductors

Inductor Guide

As described in the secret story behind the birth of the film-type inductor LQP series introduced in the November 14 article, the size of the LQP series, which could be said to be the fruit of my seniors' efforts, has been reduced in response to market demands. Demand for 0402(in mm)/01005(in inch) size (0.4 x 0.2mm) inductors, which are currently the smallest in the industry, is also gradually increasing. In addition, Murata has also developed the world's first 0201 (in mm)/ 008004 (in inch) size (0.25×0.125mm) chip inductor.

In this manner, LQP series products are becoming increasingly smaller, but the main market for high-frequency inductors is currently the 0603 (in mm)/ 0201 (in inch) size (0.6 x 0.3 mm). Murata components are also used in compact mobile devices such as smartphones. I would like to introduce the history and features of the LQP03TN_02 series as a representative example.

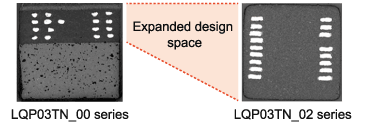

Murata Manufacturing commercialized the 0603 (in mm)/ 0201 (in inch) size high-frequency inductor LQP03TN_00 series (0.6 nH to 56 nH) in the year 2000. This series is the predecessor version of the LQP03TN_02 series, and achieved top-class high-Q characteristics in the industry in the 0603 (in mm)/ 0201 (in inch) size by forming the coil pattern using the photolithography method. As a result, the LQP03T_00 series was widely used in the mobile phone market. Figure 1 shows cross-sectional views of an LQP03TN_00 product.

This product has linear electrodes with accurate dimensions formed using the photolithography method. (See Figure 2)

For this reason, higher Q characteristics could be realized compared to products manufactured using the lamination method widely used by other manufacturers. However, the lower half of the chip is formed by the base board, so the design range in which internal electrodes can be formed is limited, and would be difficult to expand the inductance value to 56 nH or more for this product.

To overcome this issue, it is necessary to eliminate the base board and make full use of the entire chip as the design space. Therefore, efforts were made to develop a new method, and the LQP03TN_02 series was introduced in 2007 as a product with an expanded inductance value range. The inductance range of this series when first developed was 68 nH to 120 nH, and there were only four product types.

During this period, market trends toward smaller sizes and advanced functions accelerated, and the need for 0603(in mm)/0201(in inch) size inductors with high-Q characteristics also increased accordingly. To meet these demands, development was conducted to further increase the Q of all LQP03TN_00 series items, and the new LQP03TN_02 series with a fully expanded inductance lineup from 0.6 nH to 120 nH was launched in 2009.

The cross-sectional view of this series is shown in Figure 1 above.

The new series maintains the feature of linear electrodes with accurate dimensions formed by the photolithography method. In addition, full use is made of the design space, and the coil pattern has been optimized to efficiently generate magnetic flux, enabling achievement of higher Q characteristics.

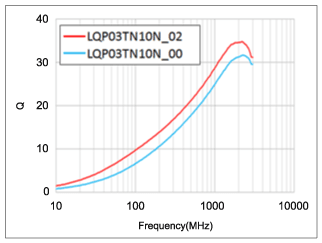

Figure 3 compares the frequency vs. Q value characteristics of 10 nH LQP03TN_00 and LQP03TN_02. This graph shows that the LQP03TN_02 achieves even higher Q characteristics.

In September 2012, the LQP03TN_02 series inductance value was increased to 270 nH, which is the highest in the industry to date in the 0603 (in mm)/ 0201 (in inch) size (as investigated by Murata as of October 2012). This provides a wide lineup that enables circuit design with an even higher degree of freedom than was previously possible.

In the future we intend to continue developing new products to meet diverse needs such as greater miniaturization, more functions, and narrower deviation.

S.S., Components Business Unit, Murata Manufacturing Co., Ltd.

The information presented in this article was current as of the date of publication. Please note that it may differ from the latest information.